aug . 26, 2025 17:27 Tilbake til listen

Infrastructure Projects with Durable HDPE Solutions

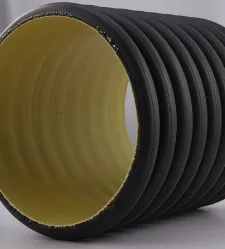

In the realm of modern infrastructure, selecting the right piping system is crucial for ensuring longevity, efficiency, and cost-effectiveness. High-Density Polyethylene (HDPE) pipes have emerged as a superior choice, offering unparalleled advantages over traditional materials. Their resilience, flexibility, and environmental benefits make them indispensable in various applications, from water supply to sewage systems.

Enhancing System Reliability with HDPE Pipes And Fittings

The integration of HDPE pipes and fittings into infrastructure projects significantly boosts system reliability. These components are known for their exceptional resistance to corrosion, abrasion, and chemical reactions, ensuring a prolonged service life. Their flexibility allows for easy installation across diverse terrains, reducing the need for additional fittings and joints. Moreover, the leak-free joints achieved through fusion welding techniques minimize water loss and prevent contamination, thereby safeguarding public health and the environment. The lightweight nature of HDPE materials also simplifies transportation and handling, leading to faster project completion times and reduced labor costs.

Optimizing Wastewater Management with HDPE Sewer Pipe

Implementing HDPE sewer pipe systems revolutionizes wastewater management by offering robust and efficient solutions. These pipes exhibit high resistance to the corrosive substances commonly found in sewage, ensuring structural integrity over extended periods. Their smooth internal surfaces reduce friction, enhancing flow rates and minimizing blockages. Additionally, the flexibility of HDPE pipes accommodates ground movements and settlements without compromising the system's functionality. This adaptability is particularly beneficial in areas prone to seismic activities or unstable soil conditions, where traditional rigid pipes might fail.

Ensuring Seamless Connectivity through HDPE Pipe Jointing

The process of HDPE pipe jointing is pivotal in establishing a continuous and leak-proof piping network. Techniques such as butt fusion and electrofusion create joints that are as strong as the pipe itself, eliminating weak points susceptible to leaks or breaks. These methods facilitate the creation of monolithic systems, which are crucial for applications requiring high-pressure tolerance and long-term reliability. Furthermore, the versatility of HDPE jointing allows for connections with various materials, enabling integration into existing infrastructure with minimal modifications.

Advancing Drainage Solutions with Perforated HDPE Pipe

The utilization of perforated HDPE pipe in drainage systems offers an effective means of managing surface and subsurface water. These pipes are designed with strategically placed perforations that allow water to enter or exit the pipe, facilitating efficient drainage in agricultural fields, roadways, and landscaping projects. Their high durability ensures consistent performance even under heavy loads and harsh environmental conditions. Moreover, the lightweight and flexible nature of HDPE pipes simplifies installation, reducing time and labor requirements. This efficiency translates into cost savings and improved project timelines.

Balancing Budget and Performance with HDPE Pipe Cost

Evaluating HDPE pipe cost involves considering both initial investment and long-term savings. While the upfront cost may be higher compared to some traditional materials, HDPE pipes offer significant savings over their lifespan due to reduced maintenance, lower repair frequencies, and extended service life. Their resistance to corrosion and chemical damage minimizes the need for replacements, and their leak-free joints prevent water loss, contributing to operational efficiency. Additionally, the ease of installation reduces labor costs and project durations, further enhancing their cost-effectiveness.

Understanding the Economic Advantages of HDPE Pipes And Fittings

Investing in HDPE pipes and fittings yields substantial economic benefits. Their durability reduces the frequency of repairs and replacements, leading to lower maintenance costs. The efficiency of installation processes decreases labor expenses, and the longevity of the system ensures a favorable return on investment. These factors collectively make HDPE systems a financially sound choice for infrastructure projects.

Evaluating Long-Term Savings with HDPE Pipe Cost

When assessing HDPE pipe cost, it's essential to consider the total cost of ownership. The initial expenditure is offset by the pipe's extended lifespan, minimal maintenance requirements, and energy-efficient performance. These attributes contribute to significant savings over time, validating the investment in HDPE piping solutions.

HDPE Pipes FAQs

Q: What are the primary applications of HDPE pipes and fittings?

A: HDPE pipes and fittings are widely used in water supply, sewage systems, gas distribution, and industrial processes due to their durability and resistance to corrosion.

Q: How does HDPE sewer pipe compare to traditional materials?

A: HDPE sewer pipes offer superior flexibility, chemical resistance, and longevity, making them more reliable and cost-effective than traditional materials like concrete or PVC.

Q: What jointing methods are used for HDPE pipes?

A: Common jointing methods include butt fusion and electrofusion, both of which create strong, leak-proof connections that enhance the integrity of the piping system.

Q: In what scenarios is perforated HDPE pipe most beneficial?

A: Perforated HDPE pipes are ideal for applications requiring efficient drainage, such as agricultural fields, roadways, and landscaping projects, due to their ability to manage water flow effectively.

Q: How does the cost of HDPE pipes compare over their lifespan?

A: Although the initial cost may be higher, HDPE pipes offer lower total ownership costs through reduced maintenance, longer service life, and improved system efficiency.

-

Transform Your Projects with Premium Hdpe Plastic Sheets

NyheterAug.26,2025

-

Revolutionizing Irrigation Efficiency with Advanced HDPE Solutions

NyheterAug.26,2025

-

Optimize Plumbing Systems with High-Quality Pipe Fittings

NyheterAug.26,2025

-

Optimize Fluid Systems with Advanced Piping Solutions

NyheterAug.26,2025

-

Infrastructure Projects with Durable HDPE Solutions

NyheterAug.26,2025

-

Enhance Structural Integrity with Advanced Polymer Sheets

NyheterAug.26,2025