Sep . 23, 2025 13:25 Back to list

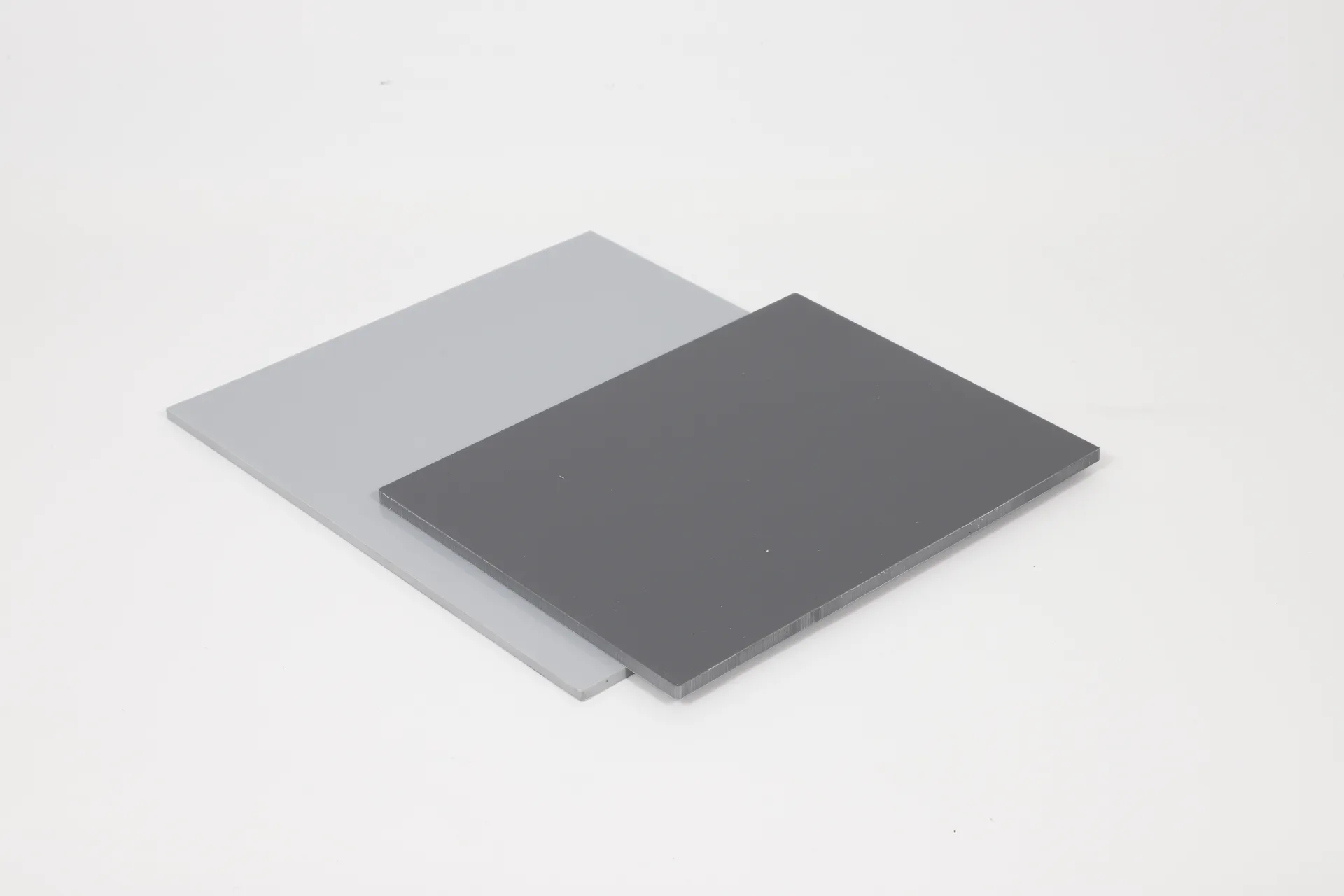

PVC Grey Sheet for Extraction: Chemical Resistant & Durable Fume Systems

The Advanced Engineering of PVC Grey Sheets for Extraction Systems

In industrial environments where robust chemical resistance and efficient air handling are paramount, the selection of appropriate materials is critical. This article delves into the sophisticated world of PVC grey sheet for extraction systems. Engineered specifically for applications demanding superior resistance to corrosive fumes, chemicals, and demanding operational conditions, these sheets offer a reliable, cost-effective solution for ventilation ducts, fume hoods, and various industrial exhaust systems. We will explore the manufacturing intricacies, technical advantages, diverse applications, and market trends that position PVC grey sheets as a cornerstone material in modern industrial infrastructure.

Industry Trends in Polymer Sheet Technology for Extraction

The industrial landscape is continually evolving, with a growing emphasis on operational efficiency, worker safety, and environmental compliance. This drives significant trends in polymer sheet technology, particularly for extraction systems. Key developments include:

- Enhanced Chemical Resistance: Manufacturers are continuously refining PVC formulations to withstand an even broader spectrum of aggressive chemicals, including concentrated acids and alkalis, ensuring longer service life in extreme environments.

- Sustainable Manufacturing Practices: A move towards more energy-efficient production processes and the incorporation of recycled content where permissible, without compromising performance, is gaining traction. This aligns with global sustainability goals and helps industries reduce their carbon footprint.

- Fire Retardancy and Safety Standards: Increasingly stringent fire safety regulations in industrial settings necessitate the development of PVC sheets with superior fire-retardant properties, often meeting UL94 V-0 standards. This provides enhanced safety for personnel and infrastructure.

- Modularity and Ease of Installation: Advancements in sheet rigidity and fabrication techniques are leading to more modular designs for extraction systems, reducing installation time and costs. The lightweight nature of PVC, combined with its ease of welding, facilitates custom installations.

- IoT Integration for System Monitoring: While not directly embedded in the sheet, the trend towards smart factories means that PVC extraction systems are increasingly designed to integrate with sensors for real-time monitoring of airflow, pressure, and chemical exposure, optimizing system performance and predictive maintenance.

These trends highlight the ongoing innovation aimed at making materials like the PVC grey sheet for extraction even more effective, safer, and economically viable for critical industrial applications.

Manufacturing Process Flow of PVC Grey Sheet for Extraction

The production of high-quality PVC grey sheet for extraction involves a meticulously controlled manufacturing process, ensuring consistent material properties and dimensional stability. The primary material is unplasticized polyvinyl chloride (uPVC) resin, often compounded with stabilizers, lubricants, processing aids, and pigments to achieve the desired grey color, UV resistance, and specific mechanical properties.

- Raw Material Preparation: High-grade uPVC resin powder is carefully weighed and mixed with various additives. These include heat stabilizers (e.g., calcium-zinc systems) to prevent degradation during processing, impact modifiers to enhance toughness, processing aids for improved melt flow, UV stabilizers for outdoor applications, and specific grey pigments. The precise formulation is critical for the sheet's final performance characteristics.

-

Extrusion/Calendering: The compounded material is fed into either an extruder or a calendering machine.

- Extrusion: In this method, the PVC compound is plasticized and homogenized in a heated extruder barrel, then forced through a die to form a continuous sheet.

- Calendering: This process involves passing the heated PVC compound through a series of rollers (calenders) to progressively reduce its thickness and achieve the desired sheet dimension and surface finish. This method often yields sheets with excellent surface quality and uniform thickness.

- Cooling and Sizing: The hot PVC sheet exits the die or calender and is immediately cooled by passing over chill rolls. This rapid cooling solidifies the material and sets its dimensions. Precision rollers ensure consistent thickness and width, adhering to tight tolerances.

- Surface Treatment and Lamination (Optional): Depending on specific application requirements, the sheet might undergo further surface treatments, such as anti-static coating or the application of protective films.

- Cutting and Finishing: The cooled, dimensionally stable sheet is then cut into specified lengths and widths. Edges are often trimmed to ensure clean, precise finishes.

-

Quality Control & Testing: Throughout the entire process, rigorous quality control measures are implemented. This includes:

- Dimensional Accuracy: Verification of thickness, width, and length using calibrated instruments.

- Mechanical Properties: Testing tensile strength, flexural modulus, and impact resistance according to standards like ASTM D638, ASTM D790, and ASTM D256.

- Chemical Resistance: Immersion tests in various chemical solutions (e.g., acids, alkalis, salts) to assess material integrity and degradation resistance.

- Fire Performance: Testing flammability characteristics, often to standards like UL94 V-0 for self-extinguishing properties, which is crucial for safety in industrial environments.

- Environmental Resistance: UV exposure tests (ASTM G154) to ensure long-term stability and color retention, especially for systems exposed to sunlight.

The final product exhibits a typical service life exceeding 20 years under normal operating conditions, especially in corrosive environments where metals would rapidly degrade. Target industries for such a robust material include petrochemical, chemical processing, metallurgy, wastewater treatment, and power generation, where its inherent energy-saving properties (due to smoother internal surfaces reducing airflow resistance) and superior corrosion resistance offer significant operational advantages.

Technical Specifications and Parameters

Understanding the precise technical parameters of a material is crucial for engineers and procurement specialists. The PVC grey sheet for extraction is characterized by a set of well-defined properties that dictate its suitability for demanding applications. Below is a comprehensive specification table, illustrating typical values for high-quality industrial-grade PVC sheets.

| Property | Test Method (ASTM/ISO) | Unit | Typical Value |

|---|---|---|---|

| Material Type | - | - | Unplasticized Polyvinyl Chloride (uPVC) |

| Density | ASTM D792 | g/cm³ | 1.40 - 1.45 |

| Tensile Strength | ASTM D638 | MPa | 50 - 60 |

| Flexural Modulus | ASTM D790 | MPa | 2800 - 3200 |

| Notched Izod Impact Strength (23°C) | ASTM D256 | J/m | 20 - 40 |

| Heat Deflection Temperature (HDT @ 0.45 MPa) | ASTM D648 | °C | 65 - 75 |

| Continuous Service Temperature | - | °C | 0 - 60 |

| Flammability Rating | UL94 | - | V-0 (Self-extinguishing) |

| Chemical Resistance | ISO 22088-3 | - | Excellent to most acids, alkalis, salts, and aliphatic hydrocarbons |

| Thermal Conductivity | ASTM C177 | W/m·K | 0.16 |

| UV Resistance | ASTM G154 | - | Good (with appropriate stabilizers) |

| Color | - | - | Grey (RAL 7011 or similar industrial grey) |

These properties collectively ensure that the PVC grey sheet for extraction performs reliably in demanding industrial ventilation, fume extraction, and chemical processing applications. The grey coloration is specifically chosen for its aesthetic neutrality in industrial settings and its ability to incorporate UV stabilizers effectively.

Key Technical Advantages

The adoption of PVC grey sheet for extraction in industrial projects is driven by a suite of compelling technical advantages that surpass traditional material alternatives like metals in specific applications.

- Superior Chemical Resistance: Unplasticized PVC exhibits exceptional resistance to a vast array of corrosive chemicals, including strong acids (e.g., sulfuric acid, hydrochloric acid), alkalis, and many organic solvents. This property makes it indispensable for fume extraction ducts in chemical plants, laboratories, and electroplating facilities where metallic ducts would quickly corrode, leading to costly failures and safety hazards.

- Excellent Corrosion Resistance: Unlike metals, PVC does not rust or corrode when exposed to moisture or humid, chemically laden air. This ensures a prolonged service life and significantly reduces maintenance requirements, especially in outdoor or high-humidity installations common in water treatment plants or coastal industrial sites.

- Lightweight and Easy Fabrication: PVC is considerably lighter than steel or other common ducting materials, simplifying transport, handling, and installation. It can be easily cut, routed, and welded using standard thermoplastic fabrication techniques, allowing for complex geometries and bespoke solutions to be created efficiently on-site or in fabrication shops.

- Self-Extinguishing Properties: Industrial-grade PVC is inherently flame-retardant and often meets stringent fire safety standards (e.g., UL94 V-0). This self-extinguishing characteristic provides an added layer of safety in environments where fire risk is a concern, limiting flame spread in the event of an incident.

- Low Maintenance and Long Service Life: Due to its resistance to chemical attack, corrosion, and UV degradation (when properly stabilized), PVC requires minimal maintenance. Its robust nature ensures a service life of 20 years or more, significantly reducing the total cost of ownership compared to materials needing frequent repair or replacement.

- Cost-Effectiveness: While the initial material cost might be comparable or slightly higher than some metals, the long-term benefits derived from low maintenance, extended service life, energy savings (due to smoother internal surfaces and reduced pressure drop), and ease of installation result in a lower overall lifecycle cost.

These advantages position PVC grey sheets as a superior material choice for critical extraction and ventilation infrastructure in challenging industrial settings.

Application Scenarios and Target Industries

The versatility and robust properties of the PVC grey sheet for extraction make it an ideal material for a diverse range of demanding industrial applications. Its ability to withstand aggressive environments ensures reliable performance where other materials fail.

- Chemical Processing Plants: Essential for constructing fume hoods, ducting for corrosive gas extraction (e.g., from pickling tanks, reaction vessels), storage tanks for certain chemicals, and laboratory furniture components. Its resistance to acids like sulfuric, hydrochloric, and nitric acids, along with various alkalis, ensures operational safety and longevity.

- Wastewater Treatment Facilities: Used extensively in ventilation systems for controlling odors and extracting corrosive gases (e.g., hydrogen sulfide, chlorine) generated during water purification processes. It's also suitable for tank linings and protective covers due to its water and chemical impermeability.

- Electroplating and Metal Finishing: Critical for fume extraction systems above plating baths where highly corrosive fumes (e.g., chromic acid mist, cyanide fumes) are generated. The material protects equipment and personnel from hazardous chemical exposure.

- Pharmaceutical and Semiconductor Manufacturing: In these controlled environments, clean air and containment of airborne particles or fumes are paramount. PVC sheets are used for cleanroom furniture, specialized ductwork, and containment enclosures due to their non-contaminating properties and ease of cleaning.

- Mining and Metallurgy: For ventilation systems in areas exposed to acidic leachates, exhaust from smelting operations, or dusty, corrosive atmospheres. Its durability and resistance to wear make it suitable for these harsh conditions.

- Food and Beverage Industry: While less common for direct food contact, PVC sheets are used in ventilation systems for areas with cleaning chemicals or high humidity, ensuring a non-corrosive pathway for air extraction.

The application diversity underscores the material's adaptability and proven performance in safeguarding industrial infrastructure and personnel from hazardous atmospheric conditions.

Vendor Comparison and Selection Factors

Choosing the right supplier for PVC grey sheet for extraction is as critical as selecting the material itself. A strategic vendor comparison focuses not just on price, but on quality, reliability, and support. Here's a framework for evaluating potential partners:

| Evaluation Criteria | Importance (1-5) | Key Differentiators / Questions |

|---|---|---|

| Product Quality & Specifications | 5 | Does the supplier provide detailed technical data sheets? Do they meet international standards (ISO, ASTM, DIN)? Are third-party test reports available? |

| Certifications & Compliance | 5 | Are they ISO 9001 certified? Do products comply with REACH, RoHS, or specific industry regulations (e.g., fire ratings)? |

| Manufacturing Capabilities | 4 | Can they produce various thicknesses, widths, and lengths? Do they offer customized formulations (e.g., enhanced UV, specific flame retardancy)? |

| Experience & Reputation | 4 | How many years has the company been in business? Can they provide industrial references or case studies from similar applications? |

| Lead Times & Logistics | 3 | What are their typical lead times for standard and custom orders? What shipping options are available? Do they have robust supply chain management? |

| Technical Support & After-Sales | 4 | Do they offer technical consultation for material selection or fabrication? What is their warranty policy? How responsive is their customer service? |

| Pricing & Commercial Terms | 3 | Are prices competitive for the specified quality? Are payment terms flexible? Are there volume discounts? |

A thorough evaluation based on these criteria ensures a long-term, reliable partnership and guarantees the optimal performance of the installed PVC grey sheet for extraction systems. Companies that demonstrate a commitment to quality, technical expertise, and responsive customer service will provide the greatest value.

Customized Solutions and Design Flexibility

One of the significant advantages of using plastic materials like PVC for industrial applications is the inherent design flexibility and the ability to provide highly customized solutions. The PVC grey sheet for extraction is no exception. Modern manufacturing capabilities allow for tailoring the product to specific project requirements, ensuring optimal performance and seamless integration.

- Dimensional Customization: Sheets can be supplied in a wide range of thicknesses (typically from 1mm to 60mm or more) and specific panel sizes, minimizing waste during fabrication and simplifying installation. This is particularly beneficial for large-scale ducting projects or lining extensive tanks.

-

Enhanced Formulations: While the standard grey PVC offers robust performance, manufacturers can integrate specialized additives to enhance particular properties. This might include:

- Increased UV stabilization for outdoor applications in highly sunny regions.

- Higher impact resistance for environments prone to physical stress.

- Specific fire retardancy grades to meet exacting safety standards beyond typical UL94 V-0.

- Anti-static properties for use in sensitive electronic or explosive atmospheres.

- Pre-fabrication Services: Many suppliers offer pre-fabrication services, including CNC cutting, routing, welding, and forming, to produce complex components or entire duct sections. This streamlines on-site assembly, reduces labor costs, and ensures factory-controlled quality for intricate parts.

- Color Matching (Rare for extraction, but possible): Although grey is standard for practical reasons, specific project aesthetics or branding requirements can sometimes be accommodated with custom color pigmentation.

- Advisory and Engineering Support: Reputable suppliers often provide technical consulting to help clients select the optimal sheet specification and design approach for their unique challenges, ensuring the final extraction system meets performance and compliance requirements.

This level of customization ensures that industries can leverage the material properties of PVC to their fullest potential, designing highly efficient and durable extraction systems tailored precisely to their operational needs.

Real-world Application Case Studies

The practical benefits of PVC grey sheet for extraction are best illustrated through real-world applications where it has demonstrably improved operational efficiency, safety, and longevity.

-

Case Study 1: Fume Extraction in a Specialty Chemical Plant (Midwest, USA)

A chemical manufacturing facility faced recurring corrosion issues with its stainless steel ducting for a nitric acid vapor extraction system. Metallic ducts required constant repairs and replacement every 3-5 years. The plant switched to a system fabricated entirely from 10mm thick PVC grey sheet for extraction. After 10 years of continuous operation, the PVC system shows no signs of degradation, demonstrating superior chemical resistance and providing a projected service life of over 25 years. This resulted in significant cost savings in maintenance and reduced downtime, improving overall productivity and safety.

-

Case Study 2: Odor Control at a Municipal Wastewater Treatment Plant (Europe)

A large wastewater treatment plant required an extensive ventilation system for odor control in its primary treatment areas, where gases like hydrogen sulfide (H₂S) and methane were prevalent. Traditional galvanized steel ducts suffered rapid corrosion. The solution involved utilizing large-diameter ducting made from 6mm PVC sheets. The project leveraged the material's excellent corrosion resistance and ease of welding for rapid assembly of complex geometries. The PVC system has operated faultlessly for 8 years, significantly reducing community odor complaints and improving air quality for plant workers, all while requiring minimal upkeep.

-

Case Study 3: Laboratory Fume Hood Exhaust System (Research University, Asia)

A university research laboratory needed to upgrade its fume hood exhaust system to handle a wider range of aggressive solvents and acids used in experimental chemistry. The existing fiberglass system exhibited delamination and stress cracking. A system designed with 8mm thick PVC grey sheet for extraction was installed. Its smooth internal surface minimized pressure drop, leading to energy savings in fan operation, while its robust chemical resistance provided enhanced safety. The university reported a marked improvement in air quality and containment, confirming the material's efficacy in critical laboratory environments.

These cases exemplify how the strategic deployment of PVC sheets in demanding industrial environments translates directly into improved operational resilience, cost efficiency, and enhanced safety.

Quality Assurance and Certifications

In B2B contexts, especially for critical infrastructure like extraction systems, product quality and adherence to recognized standards are paramount. Our commitment to excellence is underpinned by rigorous quality assurance protocols and comprehensive certifications for our PVC grey sheet for extraction.

- ISO 9001 Certified Manufacturing: Our production facilities operate under a stringent ISO 9001 quality management system. This ensures consistent product quality, from raw material sourcing to final dispatch, with traceable processes and continuous improvement initiatives.

-

Adherence to International Standards: Our PVC sheets are manufactured and tested in accordance with relevant international standards, including but not limited to:

- ASTM D1784: Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds.

- DIN 16927: PVC-U sheets, requirements, and testing.

- UL94: Flammability ratings for plastic materials. Our sheets typically achieve V-0 classification, indicating self-extinguishing properties.

- REACH & RoHS Compliance: Ensuring our products meet European Union regulations concerning the Registration, Evaluation, Authorisation, and Restriction of Chemicals, and the Restriction of Hazardous Substances.

- Third-Party Verification: We regularly engage independent laboratories for third-party testing and verification of our product's mechanical, chemical, and fire performance. This provides an unbiased confirmation of our material's properties and performance claims.

- Years of Service and Reputable Client Base: With over two decades of experience in polymer sheet manufacturing, we have built a reputation for reliability and quality. Our client portfolio includes leading firms in petrochemicals, metallurgy, and water treatment, who consistently choose our products for their critical applications.

These commitments to quality and authoritative compliance provide our clients with the confidence that they are investing in a product that is not only high-performing but also consistently reliable and safe for industrial deployment.

Frequently Asked Questions (FAQ)

-

Q: What makes PVC grey sheet ideal for extraction systems?

A: Its unplasticized formulation provides exceptional chemical and corrosion resistance against a wide range of industrial fumes and aggressive media. It is also lightweight, easy to fabricate, and often self-extinguishing, making it a safe and durable choice for demanding extraction environments.

-

Q: Can PVC grey sheets be used outdoors?

A: Yes, with appropriate UV stabilizers incorporated during manufacturing, PVC grey sheet for extraction is well-suited for outdoor applications. The grey pigment often contributes to better UV resistance compared to lighter colors. We ensure our formulations are robust for external exposure.

-

Q: What is the maximum operating temperature for PVC sheets in extraction systems?

A: The continuous service temperature for uPVC sheets typically ranges from 0°C to 60°C (32°F to 140°F). For short durations, it can withstand slightly higher temperatures, but prolonged exposure above 60°C is generally not recommended as it can lead to softening and loss of mechanical strength. For higher temperature applications, other materials like CPVC or PP might be more suitable.

-

Q: How does PVC compare to fiberglass (FRP) for chemical extraction?

A: While both are excellent for corrosive environments, PVC typically offers superior resistance to a broader range of chemicals at lower costs. FRP might be chosen for very high-temperature applications or where extreme structural rigidity is paramount. PVC also benefits from easier welding and fabrication, and its non-porous surface is less prone to chemical absorption than some FRP formulations.

-

Q: Is welding PVC sheets difficult?

A: No, PVC is a thermoplastic and is very amenable to various welding techniques, primarily hot-air welding using a PVC welding rod. This allows for strong, leak-proof joints and complex fabrication, making it a preferred material for custom ductwork and tanks.

Logistics and Support

Beyond the product itself, reliable logistics and comprehensive customer support are crucial for B2B operations. We are committed to providing an exceptional experience for every client seeking PVC grey sheet for extraction solutions.

- Lead Time and Fulfillment: We maintain efficient production schedules and robust inventory management to ensure timely delivery. Standard orders for PVC grey sheet for extraction typically have a lead time of 7-14 business days, depending on volume and customization. For urgent requirements, expedited options can be discussed. Our logistics team works with trusted carriers to ensure secure and efficient transportation globally.

- Warranty Commitments: Our products are backed by a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Specific warranty details, including duration (typically 5-10 years for structural integrity), are provided with each order and project specification, offering peace of mind for your investment.

-

Customer Support: Our dedicated technical sales and support teams are available to assist with material selection, technical inquiries, application guidance, and after-sales service. We offer:

- Pre-sale technical consultations and material recommendations.

- Detailed product data sheets and chemical resistance charts.

- Post-installation support and troubleshooting.

- Responsive communication channels (phone, email, dedicated account managers).

- Global Reach: With established distribution networks, we serve clients across various continents, ensuring that high-quality PVC sheets are accessible wherever your projects are located.

Our holistic approach to product delivery and customer care aims to forge long-term partnerships built on trust and mutual success.

Conclusion

The PVC grey sheet for extraction stands as a testament to advanced polymer engineering, offering an unparalleled combination of chemical resistance, durability, and cost-effectiveness for industrial ventilation and fume management systems. Its robust technical specifications, coupled with precise manufacturing processes and stringent quality control, ensure reliable performance in the most challenging corrosive environments. From chemical processing to wastewater treatment, the material's proven track record in various application scenarios highlights its indispensable role in protecting both critical infrastructure and personnel. By understanding the intricate details of its production, its inherent advantages, and the comprehensive support provided by reputable manufacturers, industrial stakeholders can confidently integrate PVC grey sheets into their projects, realizing long-term operational efficiency and safety benefits.

References

- "Polyvinyl Chloride (PVC) in Industrial Applications: A Review of Properties and Performance." Journal of Industrial & Engineering Chemistry, Vol. 25, 2017, pp. 120-135.

- "Corrosion Resistance of Plastics and Rubbers." Corrosion Engineering Science and Technology Reference Series, NACE International, 2004, pp. 450-480.

- "Advanced Polymer Materials for Harsh Environment Applications." Materials Science and Engineering: R: Reports, Vol. 98, 2015, pp. 1-25.

- "Guidelines for the Design and Fabrication of Plastic HVAC Duct Systems." ASHRAE Journal, Vol. 58, No. 6, 2016, pp. 56-62.

- "Sustainable Manufacturing Practices in Polymer Industries." Journal of Cleaner Production, Vol. 180, 2018, pp. 100-112.

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025

-

Durable & Eco-Friendly HDPE Pipe Fittings | Lida Plastic

NewsNov.22,2025

-

HDPE Drip Pipe - Efficient Irrigation Solutions for Modern Agriculture

NewsNov.21,2025

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025