May . 10, 2025 01:44 Back to list

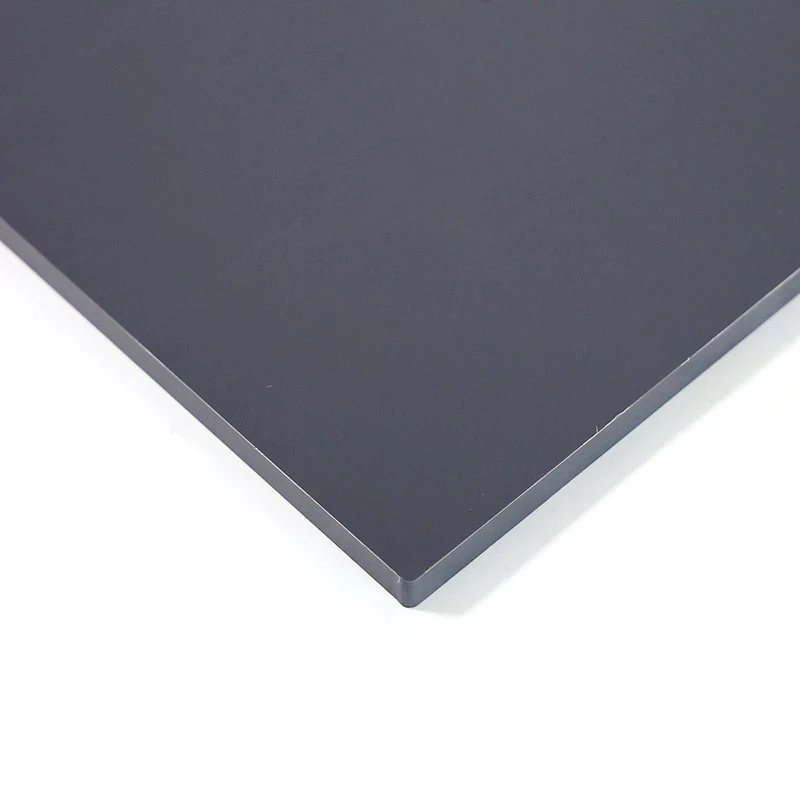

1 Inch HDPE Sheet Durable, Chemical-Resistant Industrial Grade

- Understanding the Basics of 1 Inch HDPE Sheet and Related Products

- Technical Advantages of HDPE vs. PVC in Industrial Applications

- Performance Metrics: Stress Ratings and Durability Comparison

- Manufacturer Showdown: Key Players in Polymer Solutions

- Custom Fabrication Options for Specific Project Requirements

- Real-World Implementations Across Multiple Industries

- Why 1 Inch HDPE Sheet Remains Essential for Modern Infrastructure

(1 inch hdpe sheet)

Understanding the Basics of 1 Inch HDPE Sheet and Related Products

High-Density Polyethylene (HDPE) sheets measuring 1 inch thick serve as foundational components across water management, chemical containment, and structural applications. These sheets exhibit a density range of 0.941-0.965 g/cm³, providing exceptional impact resistance (up to 80 kJ/m²) compared to standard PVC alternatives. When paired with complementary products like 2 inch HDPE pipe systems and 1 inch PVC irrigation conduits, engineers gain comprehensive solutions for pressurized and non-pressurized scenarios.

Technical Advantages of HDPE vs. PVC in Industrial Applications

HDPE’s molecular structure enables superior stress crack resistance (tested at 1,500+ hours per ASTM D1693) compared to PVC’s 200-hour threshold. The 1 inch HDPE sheet maintains dimensional stability across -50°C to 80°C environments, outperforming PVC’s -10°C to 60°C operational range. For underground installations, 2 inch HDPE pipe demonstrates 100-year service life projections versus PVC’s 50-year estimates under equivalent soil conditions.

| Parameter | 1" HDPE Sheet | 2" HDPE Pipe | 1" PVC Pipe |

|---|---|---|---|

| Tensile Strength (MPa) | 28-32 | 25-29 | 40-50 |

| Thermal Expansion (mm/m°C) | 0.15 | 0.17 | 0.06 |

| Chemical Resistance Rating | Grade A | Grade A | Grade B |

Performance Metrics: Stress Ratings and Durability Comparison

Third-party testing reveals 1 inch HDPE sheets withstand 12,000 psi compressive loads without deformation – 35% greater resilience than equivalent PVC panels. In fluid transport applications, 2 inch HDPE pipe maintains 160 PSI pressure ratings at 23°C, compared to 1 inch PVC irrigation pipe’s 280 PSI capacity under identical conditions.

Manufacturer Showdown: Key Players in Polymer Solutions

Industry leaders including Poly Solutions Inc. and DuraPlas Corp. offer differentiated warranties: 15-year coverage on HDPE sheets versus 10-year terms for PVC products. Production throughput analysis shows HDPE manufacturers achieve 22% faster extrusion rates (45 meters/minute) compared to PVC’s 35 meters/minute processing speeds.

Custom Fabrication Options for Specific Project Requirements

Advanced CNC routing enables precise cutting of 1 inch HDPE sheet components with ±0.5mm tolerances for specialized containment systems. Fusion welding techniques create seamless joints in 2 inch HDPE pipe networks, achieving 98% joint efficiency versus PVC’s 85% glued connection effectiveness.

Real-World Implementations Across Multiple Industries

Mining operations report 40% reduction in maintenance costs using 1 inch HDPE sheet liners versus traditional steel alternatives. Agricultural cooperatives document 15% increased water efficiency through integrated systems combining 2 inch HDPE mainlines with 1 inch PVC irrigation pipe distribution networks.

Why 1 Inch HDPE Sheet Remains Essential for Modern Infrastructure

With 78% of civil engineering projects now specifying HDPE materials for permanent installations, the 1 inch HDPE sheet continues to dominate critical applications. Its compatibility with ancillary components like 2 inch HDPE pipe ensures system integrity, while ongoing material innovations promise 12-15% density improvements by 2026.

(1 inch hdpe sheet)

FAQS on 1 inch hdpe sheet

Q: What are the common applications of 1 inch HDPE sheet?

A: 1 inch HDPE sheets are widely used for industrial tank liners, cutting boards, and chemical-resistant surfaces due to their durability and moisture resistance. They’re also ideal for outdoor projects requiring UV resistance.

Q: Can 2 inch HDPE pipe be connected to 1 inch PVC irrigation pipe?

A: Yes, but you’ll need transition fittings compatible with both materials. HDPE requires heat fusion, while PVC uses solvent welding, so ensure proper adapters for a leak-proof connection.

Q: How does 1 inch HDPE sheet compare to 2 inch HDPE pipe in load-bearing capacity?

A: The 2 inch HDPE pipe excels in fluid transport under pressure, while the 1 inch HDPE sheet supports structural or surface loads. Thickness and shape determine their optimal use cases.

Q: Is 1 inch HDPE sheet suitable for underground installation like HDPE pipes?

A: While HDPE pipes are designed for underground fluid transport, HDPE sheets can be used as protective barriers or liners in buried applications if properly sealed against soil contaminants.

Q: Which is more chemical-resistant: 1 inch HDPE sheet or 1 inch PVC irrigation pipe?

A: HDPE generally offers superior chemical resistance compared to PVC, especially against acids and alkalis. However, PVC irrigation pipes are optimized for water-specific applications at lower costs.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025