Jul . 22, 2025 19:01 Back to list

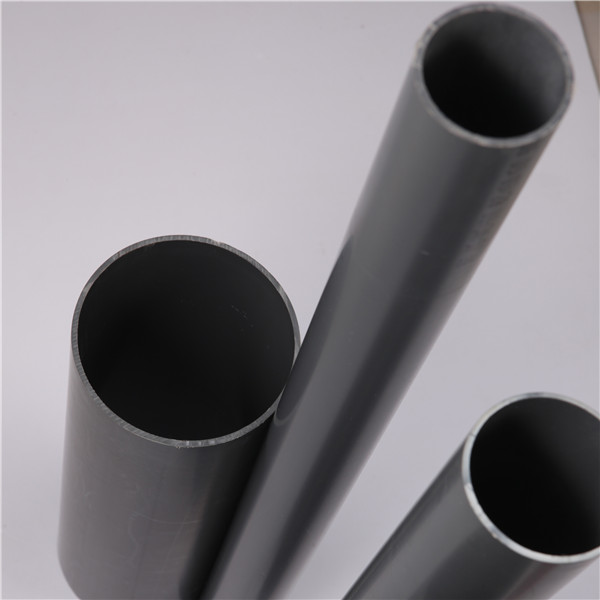

High-Quality PVC-M Water Supply Pipe for Reliable Plumbing Solutions

- Company Name:

- (Official Website)

- Contact Phone:

- 0086-312-5381013

- Mobile:

- 0086-17731201156

- Email:

- lidaplastic@ldsy.cn

- Address:

- No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250

1. What is PVC-M water supply pipe?

PVC-M water supply pipe stands for Modified Polyvinyl Chloride pipes, engineered using salinized rigid inorganic particles to fortify PVC with superior toughness and remarkable impact resistance. These pipes preserve high-strength characteristics innate to PVC, while enhancing ductility, pressure handling, and anti-cracking performance. This next-generation evolution surpasses both unplasticized (PVC-U) and modified (C-PVC) variants in several key properties, marking PVC-M water supply pipe as the preferred solution for modern water infrastructure.

PVC-M water supply pipes are widely preferred within potable water supply networks, urban municipal systems, industrial processing, and agricultural irrigation, owing to their cost-efficiency, lifespan extension, and environmentally friendly characteristics.

High impact PVC-M water supply pipes are manufactured from rigid inorganic particles for pipe toughening. This process retains the high-strength nature of PVC while boosting ductility, pressure resistance, and anti-cracking.

Standard: CJ/T272—2008 | Specification: Ф20mm—Ф800mm

For further product details, visit: PVC-M water supply pipe product page

2. Industry Trends for PVC-M water supply pipe: Market Insights & Future Growth

The PVC-M water supply pipe sector is experiencing unprecedented growth worldwide. According to Plastic Pipe Institute, global demand for high-performance, environmentally safe, and durable piping solutions is driving the adoption of materials like PVC-M in city and rural infrastructure alike.

- Global Market Growth: Estimated CAGR of over 6% by 2030 (Source)

- Urbanization & Water Scarcity: Cities increasingly opt for pipe networks offering superior longevity, corrosion-resistance, rapid installation and low leakage. PVC-M water supply pipe meets these requirements

- Regulatory Standards: Strict national and international regulations (e.g., CJ/T272—2008) are elevating the minimum technical baseline for water pipes, encouraging a transition to advanced materials like PVC-M

- Sustainability: Enhanced recyclability and low energy input in manufacture make PVC-M water supply pipe a central pillar of green infrastructure

3. Comprehensive Technical Parameters Table for PVC-M water supply pipe

| Parameter | Value / Range | Remarks |

|---|---|---|

| Standard | CJ/T272—2008 | Chinese National Standard for PVC-M water supply pipe |

| Nominal Diameter (DN) | Ф20mm—Ф800mm | Bespoke sizing for diverse networks |

| Pressure Class | 0.6 to 2.5 MPa | Variable classes suitable for several pressure ratings |

| Impact Strength | ≥8 kJ/m2 | High-impact resistance |

| Material Properties | Modified (m-PVC) with high modulus, improved toughness | Inorganic particle modification |

| Burst Pressure | ≥2.5–6.5 MPa (varies by diameter & class) | Superior to standard PVC-U/C pipes |

| Elongation at Break | ≥30% | Excellent anti-cracking and ductility |

| Service Temperature | -10℃ to +60℃ | For potable water systems |

| Lifespan | 50+ Years | If operating within guidelines |

4. Data Visualization: Technology Parameter Trends of PVC-M water supply pipe

5. Major Application Scenarios of PVC-M water supply pipe

- Municipal Water Distribution: Urban potable water transmission and delivery, benefiting from leakproofing and long system life (Source).

- Rural Water Networks: Infrastructure upgrades in rural communities with low environmental impact.

- Building Plumbing: Internal cold/hot water supply due to its hygiene and pressure/temperature resilience.

- Irrigation & Agriculture: Drip and mainline irrigation, thanks to chemical inertness and weathering resistance.

- Industrial Liquid Transport: Suitable for mildly alkaline/acidic water and special process liquids.

- Pipeline Rehabilitation: Used in trenchless/no-dig relining owing to flexibility and robust structure (Source).

6. Product Advantages: Why Choose PVC-M water supply pipe?

- Outstanding Mechanical Strength: The modified structure ensures high impact and burst resistance (Analysis).

- Exceptional Toughness: Delays crack initiation, expands tolerance to ground movement, and resists water hammer.

- Lightweight & Cost-efficient: Easy handling, fast installation, lower labor expenses than metallic or older polymers.

- Corrosion & Chemical Resistance: No rust or encrustation; inert to scale-forming ions.

- Superior Flow Characteristics: Mirror-smooth bore remains unobstructed for decades (Details).

- Environmental Sustainability: Both the raw material and final product offer high recyclability with minimal carbon footprint (Details).

7. Professional Q&A for PVC-M water supply pipe Technical Terms

8. PVC-M Water Supply Pipe: A Game Changer in Urban Hydraulic Engineering

As highlighted, PVC-M water supply pipe aligns with global calls for robust, efficient, and green water transport infrastructure. Its superior toughness, pressure rating, and reliability under demanding application scenarios enable compliance with contemporary municipal needs. Guidance from industry forums such as the PVC4Pipes Association and technical journals forecast further innovations, with enhanced composites and real-time monitoring technologies expected in the next decade.

PVC-M water supply pipe not only resolves challenges of legacy materials but also paves the way for higher safety, efficiency, and sustainability. Authorities, engineers, and developers are encouraged to consider this revolutionary product as their backbone for all modern, long-life water infrastructure projects.

- “PVC-M: Modified Unplasticized Polyvinyl Chloride Pipes — Properties and Applications,” PVC4Pipes Association, https://www.pvc4pipes.com/materials/pvc-m/

- “Water Transmission and Distribution Design and Applications,” Water Environment Federation Technical Bulletin, https://www.wef.org/resources/publications/

- “Analysis of the Toughness and Fracture Behavior of PVC-M Compared to Standard PVC Pipes,” Construction and Building Materials, Elsevier, https://www.sciencedirect.com/science/article/pii/S0950061819307965

- PVC Pipe Association. “Industry News,” https://www.plasticpipe.org/resources/industry-news.html

- “Market Insights: Global PVC Pipe Trends,” MarketResearchFuture, https://www.marketresearchfuture.com/reports/pvc-pipes-market-1818

- “PVC-M Pipes in Trenchless Rehabilitation,” Trenchlesspedia, https://www.trenchlesspedia.com/definition/3203/pvc-m-pipes

- “Sustainability of PVC-M Water Pipes,” PVC.org, https://pvc.org/sustainability/

Phone: 0086-312-5381013 Email: lidaplastic@ldsy.cn

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025