Oct . 23, 2025 05:00 Back to list

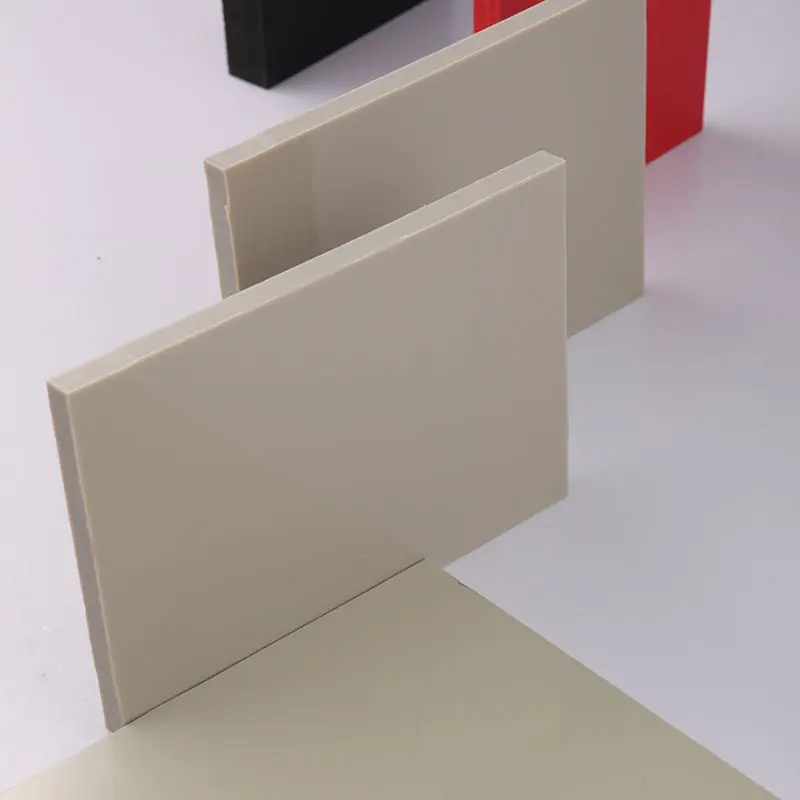

PP Rigid Sheet | Chemical Resistant, Custom Sizes & Colors

PP Rigid Sheet is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PP Rigid Sheet Overview

- Benefits & Use Cases of PP Rigid Sheet in Manufacturing of plastic sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PP Rigid Sheet from Baoding Lida Plastic Industry Co., Ltd

PP Rigid Sheet Overview

PP Rigid Sheet is an extruded polypropylene sheet engineered for high stiffness, excellent chemical resistance, and clean fabrication in industrial environments. Within the plastic product industry—especially in the Manufacturing of plastic sheets, pipes, and profiles—it is a workhorse material for tanks, ventilation components, liners, and formed parts. Typical characteristics of PP include a low density of around 0.91 g/cm³, very low moisture absorption, and a melting range near 160–170°C, supporting service temperatures commonly up to about 100°C depending on the application. Fabricators value that PP is readily weldable (hot-air and extrusion welding), machinable, and suitable for thermoforming.

- Typical specifications requested by B2B buyers include thicknesses from 1–30 mm, widths up to 1000–2000 mm, and options for smooth or matte finishes to suit bonding, printing, or forming processes.

- In a representative fabrication scenario, switching from heavier materials to PP Rigid Sheet reduces component weight, simplifies handling, and improves corrosion resistance in chemical service, contributing to fewer maintenance interventions.

- Baoding Lida Plastic Industry Co., Ltd is a reliable manufacturer providing consistent gauge control, flatness, and color customization, backed by rigorous quality control and responsive technical support for industrial buyers.

Benefits & Use Cases of PP Rigid Sheet in Manufacturing of plastic sheets, pipes, and profiles

In sheet, pipe, and profile manufacturing, PP Rigid Sheet serves as both a finished product and a versatile semi-finished stock. Fabricators convert sheets into tanks, fume ducts, baffles, splash guards, machine covers, and trays, while also cutting blanks for PP pipe flanges and fittings. The material’s weldability enables strong, homogeneous joints in butt, hot-air, and extrusion welding, which is essential for chemical handling systems, water treatment plants, and ventilation lines. For thermoforming, PP maintains good definition and impact performance, making it suitable for protective housings, transport trays, and cabinet components.

- Competitive advantages: low density (lighter assemblies), broad chemical resistance (acids, bases, salts), good heat resistance versus PVC, low moisture uptake, and excellent fatigue resistance for living-hinge type features.

- Production benefits: consistent thickness tolerance supports precision CNC routing; stable flatness reduces scrap; and surface options help downstream printing, lamination, or bonding with approved methods.

- Baoding Lida Plastic Industry Co., Ltd leverages robust extrusion know-how to deliver repeatable batches and custom dimensions, assisting OEMs and processors in standardizing components and shortening lead times.

Cost, Maintenance & User Experience

From a total cost of ownership perspective, PP Rigid Sheet offers compelling value. The material’s low density reduces freight and handling costs; fast welding and machining shorten fabrication time; and robust chemical resistance cuts corrosion-related downtime. Over multi-year service, these factors translate into favorable ROI for components exposed to acids, alkalis, and cleaning agents. Maintenance is straightforward: PP surfaces are non-porous and easy to clean with mild detergents; scale and residue are less prone to adhere compared with some alternatives. For outdoor or UV-intensive settings, buyers typically specify UV-stabilized grades or provide shielding to extend life.

- Fabricator feedback highlights consistent gauge, flatness, and weldability as key reasons for selecting Baoding Lida Plastic Industry Co., Ltd sheets—helping reduce rework and improve throughput.

- Best-practice tips: use mechanical fastening or welding rather than structural adhesives; pre-dry is generally unnecessary due to low moisture uptake; and adopt approved welding parameters for leak-tight assemblies.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping material selection. PP is halogen-free and widely recyclable (resin identification code 5), and its low density supports material and transport efficiency. As regulatory frameworks emphasize safer chemistries and circularity, many manufacturers are shifting from heavier or halogenated materials to PP where performance allows. In parallel, growth sectors—water treatment, chemical processing, EV and battery plants, and semiconductor support infrastructure—require corrosion-resistant, weldable plastics that keep uptime high and maintenance low.

- Baoding Lida Plastic Industry Co., Ltd positions PP Rigid Sheet as a responsible choice by focusing on process efficiency, scrap reduction, and consistent quality that minimizes customer waste.

- The company partners with B2B buyers on specification guidance and documentation needs, supporting compliance-driven projects and long-term supply stability in globally competitive markets.

Conclusion on PP Rigid Sheet from Baoding Lida Plastic Industry Co., Ltd

For B2B decision makers in the manufacturing of plastic sheets, pipes, and profiles, PP Rigid Sheet delivers the balanced performance, fabrication ease, and lifecycle value needed to compete. Its chemical resistance, weldability, and low density help optimize both production and end-use reliability. Baoding Lida Plastic Industry Co., Ltd combines dependable extrusion quality with attentive service, making it a trusted partner from prototyping to volume supply. Contact us: email: lidaplastic@ldsy.cn — Visit our website: https://www.lidaplastic.com

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025