Oct . 16, 2025 13:35 Back to list

PVC Rigid Sheet(UV Stabilized) – Weatherproof & Tough

PVC Rigid Sheet(UV Stabilized) is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Rigid Sheet(UV Stabilized) Overview

- Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) Overview

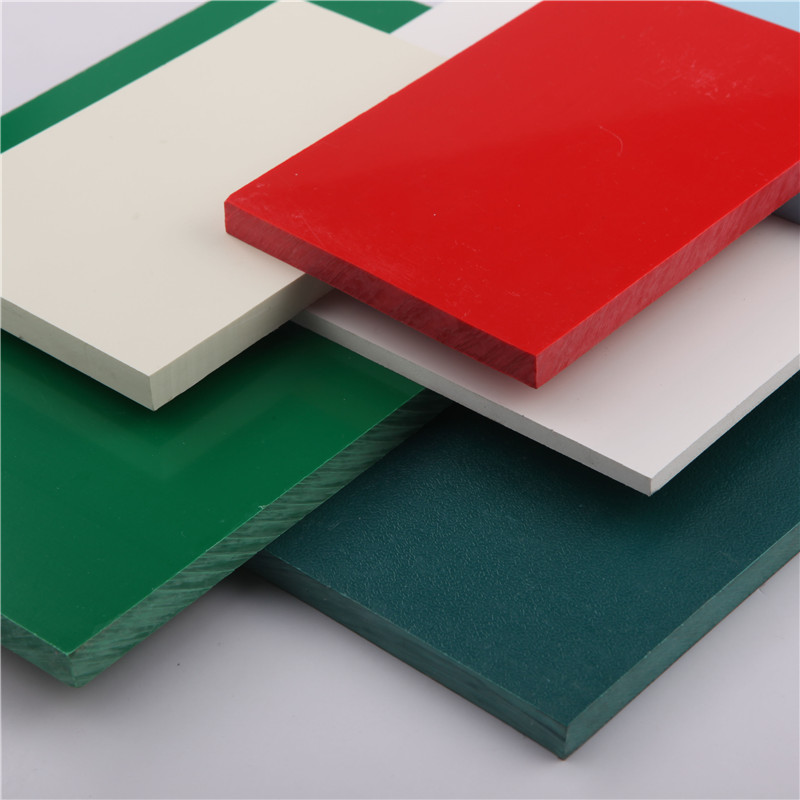

Engineered for outdoor durability and structural integrity, PVC Rigid Sheet(UV Stabilized) is an unplasticized PVC sheet compounded with UV-absorbers and stabilizers to resist yellowing, embrittlement, and surface chalking. In the plastic product industry—especially the manufacturing of plastic sheets, pipes, and profiles—this substrate is valued for its consistent mechanical performance, flame retardancy, and outstanding chemical resistance. Typical specifications include thickness options from 0.8–30 mm, widths up to common industrial standards, smooth or matte finishes, and colors such as grey, white, and custom tones. Key properties often targeted by engineers include density around 1.35–1.45 g/cm³, tensile strength in the 45–55 MPa range, Vicat softening temperature around 73–80°C, and UL 94 V-0 self-extinguishing behavior at suitable gauges.

Baoding Lida Plastic Industry Co., Ltd manufactures PVC Rigid Sheet(UV Stabilized) with strict thickness tolerance, uniform surface quality, and stable weathering performance for long-term outdoor use. The material machines well (CNC, routing, drilling), bonds reliably with industry adhesives, and can be thermoformed within defined temperature windows. Whether the end product is a protective panel, cladding component, equipment guard, or fabricated profile, Baoding Lida ensures repeatable quality across batches and supports OEM requirements from prototyping through scale-up.

Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

For manufacturers of plastic sheets, pipes, and profiles, PVC Rigid Sheet(UV Stabilized) delivers a balanced combination of weatherability, rigidity, and workability. Common applications include exterior cladding and façades, outdoor electrical and equipment enclosures, chemical processing components (tanks, ducting, splash guards), signage and displays, protective covers, cleanroom fit-outs, and machine housings. The UV-stabilized formulation preserves color and mechanical properties under prolonged sunlight, supporting long service life in harsh environments.

Competitive advantages include excellent chemical resistance versus many acids and alkalis, intrinsic flame retardancy, dimensional stability for precise fabrication, and cost-effectiveness compared with alternatives like polycarbonate or acrylic in UV-exposed, non-optical applications. Baoding Lida Plastic Industry Co., Ltd leverages application-driven compounding, consistent extrusion, and customizable formats (colors, cut-to-size, protective films) to meet B2B specifications. Their technical team assists with material selection, bonding/printing recommendations, and forming parameters so that project teams reduce trial-and-error, accelerate time-to-market, and achieve reliable fit, finish, and durability.

Cost, Maintenance & User Experience

Total cost of ownership with PVC Rigid Sheet(UV Stabilized) is favorable due to long outdoor lifespan, reduced repainting or replacement cycles, and low maintenance. The sheet resists corrosion, does not require anti-rust treatments, and cleans easily with mild detergents—helping operators minimize downtime. Its predictable fabrication behavior (cutting, routing, drilling, bending, and thermoforming) reduces scrap and tooling wear, lowering production waste and improving throughput.

Customers in the plastic product industry report improved ROI when replacing painted metals or non-UV-stabilized plastics, citing fewer warranty claims and more stable aesthetics over time. Fabricators value the sheet’s consistent thickness and surface smoothness for CNC machining and digital printing, and installers appreciate its balanced stiffness-to-weight ratio for easier handling on site. Over multi-year deployments in signage and outdoor enclosures, feedback indicates stable color retention and mechanical integrity, translating into tangible lifecycle savings for B2B buyers managing fleets of assets across multiple locations.

Sustainability & Market Trends in manufacturing

As manufacturers align with stricter environmental standards and extended product lifecycles, PVC Rigid Sheet(UV Stabilized) supports sustainability goals through durability, repairability, and recyclability at end of life. Industry trends include the shift toward calcium-zinc stabilization systems, REACH and RoHS compliance, and process optimizations that reduce energy consumption per kilogram of extruded sheet. Extended outdoors service life curbs replacement frequency, cutting material and logistics footprints for large deployments.

Market demand is growing in building products, infrastructure, transportation, and industrial equipment—segments that require weatherable, flame-retardant, and chemically resistant materials. Baoding Lida Plastic Industry Co., Ltd invests in quality control and formulation refinement to meet evolving regulations while delivering consistent performance globally. With application support for bonding, printing, and forming, the company helps B2B decision makers design more durable assemblies, reduce maintenance emissions, and progress toward circularity via scrap recovery and material take-back where feasible.

Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) provides the outdoor resilience, mechanical stability, and fabrication efficiency that manufacturers of plastic sheets, pipes, and profiles need. From cladding and industrial enclosures to signage and chemical process components, it offers strong lifecycle value and dependable performance. Backed by Baoding Lida Plastic Industry Co., Ltd’s manufacturing expertise and application support, your teams can accelerate production and reduce total cost of ownership.

Contact us: email: lidaplastic@ldsy.cn

Visit our website: https://www.lidaplastic.com

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025