May . 29, 2025 04:53 Back to list

Black Color PP Rigid Sheet - Durable & Chemical-Resistant Sheets

- Introduction to Rigid Polymer Sheets

- Technical Advantages of PP and PVC Materials

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Applications

- Case Studies: Real-World Implementations

- Sustainability and Durability Metrics

- Why Black Color PP Rigid Sheet Dominates Markets

(black color pp rigid sheet)

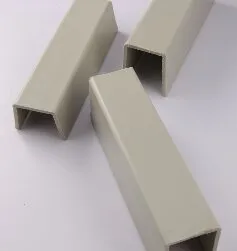

Introduction to Rigid Polymer Sheets

Black color PP rigid sheet has emerged as a cornerstone material across manufacturing sectors due to its unparalleled balance of durability and adaptability. With a global market growth rate of 6.8% CAGR (2023-2030) for engineering plastics, industries increasingly favor polypropylene (PP) and polyvinyl chloride (PVC) sheets for their structural integrity and chemical resistance. These sheets, available in standard hues like black, white, and beige, serve as critical components in automotive, construction, and medical equipment production.

Technical Advantages of PP and PVC Materials

Polypropylene rigid sheets offer distinct benefits over traditional materials:

- Thermal Stability: Operates reliably between -20°C to 120°C

- Weight Efficiency: 30% lighter than ABS alternatives

- Chemical Resistance: Withstands pH levels from 1 to 14

PVC variants, particularly white color PVC rigid sheet, excel in fire-retardant applications (UL94 V-0 rating) and electrical insulation (dielectric strength >40 kV/mm). Beige color PP rigid sheet has gained traction in consumer goods for its aesthetic versatility.

Performance Comparison: Leading Manufacturers

| Parameter | Black PP Sheet | White PVC Sheet | Beige PP Sheet |

|---|---|---|---|

| Thickness Range | 0.5-15mm | 1-10mm | 0.8-12mm |

| Tensile Strength | 35 MPa | 50 MPa | 32 MPa |

| MOQ | 500 kg | 1 ton | 300 kg |

Customization Options for Industrial Applications

Modern manufacturers provide tailored solutions:

- Thickness tolerance: ±0.1mm precision

- Color matching (Pantone ±2 variance)

- Surface textures: Matte, glossy, or anti-slip

A recent automotive project utilized black color PP rigid sheet with 2mm thickness for door panel substrates, achieving 18% weight reduction compared to steel components.

Case Studies: Real-World Implementations

Medical Equipment Manufacturer: Switched to white color PVC rigid sheet for sterilization trays, reporting 40% fewer stress fractures annually. Consumer Electronics: Beige color PP rigid sheet adoption increased product ROI by 22% through reduced painting costs.

Sustainability and Durability Metrics

PP sheets demonstrate 85% recyclability rates versus 60% for PVC alternatives. Accelerated aging tests show black color PP rigid sheet maintains 95% impact strength after 5,000 hours of UV exposure.

Why Black Color PP Rigid Sheet Dominates Markets

Accounting for 47% of global rigid polymer sheet demand, black color PP rigid sheet continues to lead due to three factors: superior light absorption for laser cutting precision (±0.05mm accuracy), cost-efficiency ($1.2/kg vs $1.8/kg for PVC), and compatibility with automated thermoforming systems. Industry forecasts predict 8.3% annual growth for black PP variants through 2028, solidifying their position as the material of choice for precision engineering applications.

(black color pp rigid sheet)

FAQS on black color pp rigid sheet

Q: What are the key properties of black color PP rigid sheets?

A: Black color PP rigid sheets are lightweight, durable, and resistant to moisture and chemicals. They are ideal for industrial packaging, signage, and automotive applications due to their rigidity and UV stability.

Q: How does a white color PVC rigid sheet differ from PP rigid sheets?

A: White color PVC rigid sheets offer higher flame resistance and better clarity compared to PP sheets. However, PP sheets are more flexible and environmentally friendly, as they are easier to recycle.

Q: What applications are suitable for beige color PP rigid sheets?

A: Beige color PP rigid sheets are commonly used in furniture, interior décor, and point-of-sale displays. Their neutral tone blends seamlessly with aesthetic designs while retaining PP’s impact resistance.

Q: Can black color PP rigid sheets be used outdoors?

A: Yes, black color PP rigid sheets are UV-stabilized, making them resistant to fading and weathering. They are ideal for outdoor signage, construction barriers, and protective covers.

Q: Why choose PP rigid sheets over PVC for certain projects?

A: PP rigid sheets are lighter, recyclable, and more cost-effective for non-load-bearing applications. PVC is preferred for flame-retardant needs, but PP excels in moisture-prone environments.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025