Aug . 21, 2025 20:40 Back to list

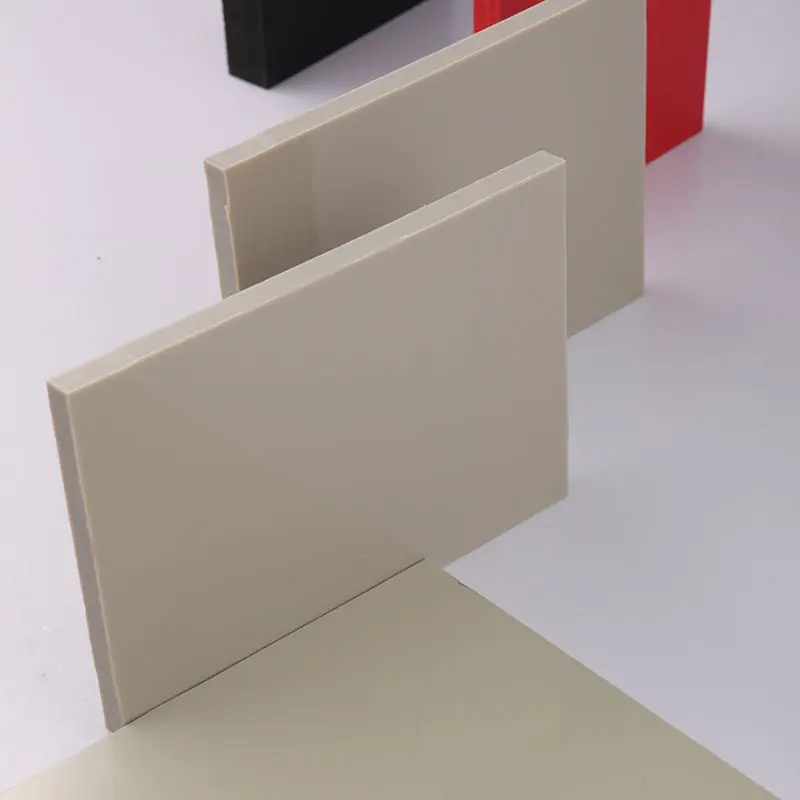

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

Understanding the Versatility and Performance of PP Rigid Sheet

In the realm of advanced material solutions, PP Rigid Sheet stands out as a highly versatile and dependable thermoplastic product, integral to a myriad of industrial and commercial applications. Propylene homopolymer or copolymer forms the fundamental basis of these sheets, bestowing upon them a unique blend of chemical resistance, high stiffness, and excellent dielectric properties. This section will delve into the core characteristics of PP Rigid Sheet, exploring its market significance, prevailing industry trends, and the fundamental reasons behind its widespread adoption across diverse sectors.

The global demand for high-performance plastic sheets continues to expand, driven by innovation in sectors such as chemical processing, water treatment, automotive, and packaging. PP Rigid Sheet, often lauded for its environmental advantages—being fully recyclable—is perfectly positioned to meet these evolving demands. Current trends indicate a significant shift towards more sustainable and durable materials, where polypropylene's inherent characteristics of longevity and recyclability make it a preferred choice over traditional materials. Furthermore, advancements in manufacturing technologies are enabling the production of PP Rigid Sheet with enhanced surface finishes, tighter tolerances, and specialized functionalities, expanding its utility even further.

From robust chemical tanks and corrosion-resistant ducting in industrial settings to lightweight and durable components in consumer electronics, the applications for PP Rigid Sheet are continuously diversifying. Its inherent resistance to most acids, alkalis, and organic solvents makes it indispensable in environments where chemical inertness is paramount. Moreover, its relatively low density contributes to significant weight savings, an increasingly critical factor in transportation and energy-efficient designs. Understanding the foundational aspects of this material is crucial for any B2B decision-maker seeking optimal performance and cost-effectiveness in their material procurement strategies.

The Advanced Manufacturing Process of PP Rigid Sheet

The production of high-quality PP Rigid Sheet is a sophisticated industrial process that requires precision engineering and stringent quality control at every stage. Unlike metals that might undergo casting or forging, polypropylene sheets are primarily manufactured through extrusion or calendering, processes optimized for thermoplastic polymers.

Material Selection and Preparation

The journey begins with the selection of premium-grade polypropylene resin. This can be a homopolymer (for higher stiffness and heat resistance) or a copolymer (for improved impact strength and flexibility, especially at low temperatures). Additives such as UV stabilizers, flame retardants, colorants, and impact modifiers are meticulously blended with the base resin to achieve specific performance characteristics. This precise compounding ensures that the final PP Rigid Sheet meets the rigorous demands of its intended application.

Extrusion Process

Extrusion is the predominant method for producing PP Rigid Sheet. The prepared resin mixture is fed into an extruder, a large machine equipped with a rotating screw. As the screw turns, it melts the plastic and forces it through a heated die, which is shaped to produce a continuous sheet. The temperature profile within the extruder is carefully controlled to ensure uniform melting and prevent degradation of the polymer. Key stages of extrusion include:

- Feeding and Melting: Polypropylene pellets are fed into the extruder barrel where they are gradually melted by a combination of heating elements and shear friction from the rotating screw.

- Metering and Pumping: The molten polymer is homogenized and pumped forward by the screw towards the die.

- Die Forming: The molten plastic is forced through a flat-sheet die, which shapes it into a continuous sheet of the desired width and initial thickness.

- Cooling and Calendering: The hot sheet emerges from the die and immediately enters a set of polished, temperature-controlled rollers (calendering rolls). These rolls cool the sheet, precisely control its thickness, and impart the desired surface finish (e.g., smooth, embossed). This stage is critical for achieving dimensional stability and superior surface quality of the PP Rigid Sheet.

- Trimming and Cutting: Once cooled and dimensionally stable, the edges of the sheet are trimmed, and the continuous sheet is cut into specific lengths or rolled up, depending on customer requirements.

Quality Control and Testing Standards

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the PP Rigid Sheet meets international standards and customer specifications. This includes:

- Dimensional Accuracy: Thickness, width, and length are continuously monitored using inline sensors and verified through manual measurements.

- Mechanical Properties: Samples are regularly tested for tensile strength (ASTM D638), flexural modulus (ASTM D790), impact strength (ASTM D256), and hardness.

- Chemical Resistance: Immersion tests are conducted to verify resistance to specific acids, alkalis, and solvents, adhering to standards like ASTM D543.

- Thermal Properties: Heat deflection temperature (ASTM D648) and vicat softening point (ASTM D1525) are crucial for high-temperature applications.

- Surface Quality: Inspection for defects such as scratches, bubbles, or discoloration.

- Certifications: Manufacturers typically adhere to ISO 9001 for quality management and ISO 14001 for environmental management. Product-specific certifications may include FDA compliance for food contact applications or ROHS compliance for electronics.

The typical service life of a well-manufactured PP Rigid Sheet can range from 10 to 50 years, depending on the specific application, environmental exposure (especially UV radiation if not stabilized), and mechanical stresses. For instance, a PP Rigid Sheet used in an indoor chemical tank lining will far outlast one exposed to continuous outdoor UV radiation without proper stabilization.

Technical Parameters and Specifications of PP Rigid Sheet

Understanding the precise technical parameters of PP Rigid Sheet is crucial for engineers and procurement specialists to ensure optimal material selection for specific applications. Polypropylene's molecular structure—specifically its isotactic arrangement—gives rise to its semi-crystalline nature, influencing its mechanical, thermal, and chemical properties.

Key Material Properties

- Density: Typically ranges from 0.90 to 0.91 g/cm³, making it one of the lightest commercial plastics. This low density is a significant advantage in applications where weight reduction is critical, such as automotive interior components or portable equipment.

- Tensile Strength: Ranging from 25 to 40 MPa, indicating its resistance to breaking under tension. Homopolymers generally exhibit higher tensile strength.

- Flexural Modulus: Approximately 1.0 to 1.8 GPa, demonstrating its stiffness and resistance to bending. A higher modulus indicates a more rigid material.

- Heat Deflection Temperature (HDT): Typically between 90°C and 110°C at 0.45 MPa, which defines the temperature at which the material deforms under a specific load. This property is vital for applications exposed to elevated temperatures.

- Chemical Resistance: Excellent resistance to a wide range of inorganic acids, alkalis, salts, and many organic solvents. This 'chemical inertness' is a primary driver for its use in chemical processing equipment.

- Dielectric Strength: High dielectric properties make it suitable for electrical insulation applications, typically ranging from 50 to 80 kV/mm.

- Impact Strength: Polypropylene generally has good impact resistance, which can be further enhanced by copolymerization or compounding with rubber modifiers. Izod impact strength can range from 20 J/m to 100 J/m (notched).

- Operating Temperature Range: Generally suitable for continuous use from -10°C to +100°C, with intermittent exposure possible at higher temperatures.

Typical PP Rigid Sheet Product Specifications Table

The following table provides a general overview of typical technical parameters for standard PP Rigid Sheet, though specific values may vary based on grade (homopolymer, copolymer), additives, and manufacturer. These values are based on common industry standards such as ASTM and ISO for material testing.

| Property | Test Method | Typical Value (Homopolymer PP) | Typical Value (Copolymer PP) |

|---|---|---|---|

| Density | ASTM D1505 / ISO 1183 | 0.90 - 0.91 g/cm³ | 0.90 - 0.91 g/cm³ |

| Tensile Strength at Yield | ASTM D638 / ISO 527 | 30 - 40 MPa | 25 - 35 MPa |

| Tensile Elongation at Break | ASTM D638 / ISO 527 | >50% | >100% |

| Flexural Modulus | ASTM D790 / ISO 178 | 1.4 - 1.8 GPa | 1.0 - 1.5 GPa |

| Notched Izod Impact Strength (23°C) | ASTM D256 / ISO 179 | 20 - 50 J/m | 40 - 100 J/m |

| Heat Deflection Temperature (0.45 MPa) | ASTM D648 / ISO 75 | 95 - 110 °C | 85 - 100 °C |

| Vicat Softening Point | ASTM D1525 / ISO 306 | 145 - 155 °C | 135 - 145 °C |

| Continuous Use Temperature | Industry Standard | -10 to +100 °C | -20 to +90 °C |

| Coefficient of Linear Thermal Expansion | ASTM E831 | 90 - 120 x 10⁻⁶ K⁻¹ | 100 - 150 x 10⁻⁶ K⁻¹ |

| Water Absorption (24h) | ASTM D570 | <0.01% | <0.01% |

These specifications highlight the robust nature of PP Rigid Sheet, making it an ideal candidate for demanding applications where durability, chemical inertness, and thermal stability are paramount.

Diverse Application Scenarios of PP Rigid Sheet

The exceptional combination of properties offered by PP Rigid Sheet makes it an indispensable material across a vast spectrum of industries. Its robust performance, particularly in corrosive environments and applications requiring high strength-to-weight ratios, ensures its continued demand.

Chemical and Petrochemical Industry

One of the primary sectors benefiting from PP Rigid Sheet is the chemical and petrochemical industry. Its unparalleled resistance to a broad range of aggressive chemicals, including strong acids, alkalis, and solvents, makes it an ideal material for:

- Chemical Storage Tanks: For safe and long-term containment of various corrosive liquids. The seamless fabrication possible with PP sheets minimizes leak points, enhancing safety.

- Fume Hoods and Ventilation Systems: In laboratories and industrial facilities where corrosive fumes are present, PP ducting and hoods provide excellent corrosion resistance and extend the life of ventilation infrastructure.

- Process Piping and Linings: As liners for steel tanks or components in process lines, enhancing the chemical resistance of metal structures and reducing maintenance.

- Scrubbers and Purifiers: Components within gas scrubbers that handle corrosive exhaust gases.

Water Treatment and Environmental Engineering

In water and wastewater treatment plants, PP Rigid Sheet is widely used due to its non-toxicity, corrosion resistance, and ease of fabrication.

- Holding Tanks and Basins: For pure water, reverse osmosis (RO) systems, and various stages of wastewater treatment.

- Filter Press Plates: In filtration systems, PP plates are preferred due to their chemical inertness and mechanical strength under pressure.

- Ventilation Systems: For air treatment within facilities that may have corrosive atmospheres.

Electroplating and Surface Finishing

The electroplating industry relies heavily on materials that can withstand aggressive chemical baths and electrical currents. PP Rigid Sheet excels in this environment:

- Electroplating Tanks: Construction of the tanks themselves or as liners for steel tanks, resisting acids like sulfuric acid, hydrochloric acid, and various plating solutions.

- Anode and Cathode Holders: Offering both chemical resistance and good electrical insulation.

- Drip Trays and Sumps: Containing spills and preventing corrosion of surrounding structures.

Automotive and Transportation

The lightweight and durable nature of PP Rigid Sheet makes it increasingly valuable in the automotive sector for improving fuel efficiency and reducing overall vehicle weight.

- Interior Trim Components: Door panels, dashboards, and cargo liners.

- Battery Housings: Providing resistance to battery acids and impact.

- Under-the-Hood Applications: Reservoirs and ducting where heat and chemical resistance are required.

Construction and Architecture

For building and construction, PP Rigid Sheet is used for its moisture resistance, rigidity, and ease of fabrication.

- Partition Walls and Ceiling Panels: Especially in cleanrooms or areas requiring high hygiene and moisture resistance.

- Protective Barriers: In areas susceptible to impact or chemical splashes.

- Damp-Proofing Membranes: Providing an effective barrier against moisture.

Packaging and Storage Solutions

Its lightweight and printable surface make PP Rigid Sheet popular for packaging.

- Reusable Totes and Bins: Durable and lightweight for logistics and storage.

- Protective Packaging: For sensitive electronics or industrial components.

- Signage and Displays: Indoor and short-term outdoor signage due to its printability and rigidity.

In each of these scenarios, the inherent advantages of PP Rigid Sheet—such as its corrosion resistance, lightweight nature, and excellent dielectric properties—translate into significant benefits for the end-user, including reduced maintenance costs, extended operational life, and improved system efficiency. For example, in a chemical processing plant, replacing traditional metal components with PP Rigid Sheet structures can lead to substantial energy savings due to lighter weight, and drastically cut down on costly repairs associated with corrosion.

Technical Advantages and Customization Solutions for PP Rigid Sheet

Beyond its core properties, the true value of PP Rigid Sheet lies in its compelling technical advantages over alternative materials and the extensive customization possibilities it offers to meet precise industrial requirements.

Superior Technical Advantages

- Exceptional Chemical Resistance: As discussed, this is a cornerstone advantage, providing durability in environments where metals would corrode and other plastics might degrade. This reduces downtime and replacement costs.

- High Strength-to-Weight Ratio: PP Rigid Sheet is significantly lighter than many traditional materials like steel, yet offers considerable structural integrity. This leads to reduced transportation costs, easier installation, and improved energy efficiency in moving applications.

- Excellent Dielectric Properties: Its ability to resist the flow of electrical current makes it an ideal insulator, crucial for electrical enclosures and components in sensitive environments.

- Thermal Stability: Good heat deflection temperatures and a broad operating range allow it to perform reliably in diverse temperature conditions.

- Ease of Fabrication: PP Rigid Sheet can be easily cut, routed, welded, thermoformed, and machined using standard plastic fabrication techniques. This flexibility allows for complex designs and seamless integration into existing systems. Welding, particularly hot gas or extrusion welding, creates strong, leak-proof joints, critical for tanks and ducts.

- Low Moisture Absorption: With water absorption rates typically below 0.01%, it maintains dimensional stability and properties even in humid or submerged conditions, preventing issues like swelling or property degradation common in other materials.

- Food Contact and Medical Grade Options: Specific grades of PP Rigid Sheet can meet stringent FDA or other regulatory requirements, making them safe for use in food processing, pharmaceutical, and medical applications.

- Eco-Friendliness and Recyclability: Polypropylene is a thermoplastic that is readily recyclable, contributing to sustainable manufacturing practices and a circular economy. This also helps companies meet their environmental compliance goals.

Tailored Customization Solutions

Leading manufacturers offer extensive customization options for PP Rigid Sheet to precisely match client specifications:

- Thickness and Dimensions: Available in a wide range of thicknesses (from 2mm to 100mm or more) and custom sheet sizes, minimizing waste and optimizing material usage for large-scale projects.

- Colors: While natural (translucent white) is common, sheets can be pigmented to virtually any color to meet aesthetic requirements or for color-coding in industrial settings.

- Surface Finishes: Options include smooth, matte, textured, or embossed surfaces for specific functional or aesthetic needs, such as anti-slip properties or improved bonding surfaces.

- Additives for Enhanced Properties:

- UV Stabilizers: Essential for outdoor applications to prevent degradation from ultraviolet radiation, significantly extending service life.

- Flame Retardants: To meet specific fire safety standards (e.g., UL 94 V-0 for certain applications), crucial in construction or electrical enclosures.

- Anti-Static Agents: For applications in electronics manufacturing or explosive environments to dissipate static electricity.

- Impact Modifiers: To increase toughness and resistance to brittle fracture, especially in low-temperature environments.

- Glass Fiber Reinforcement: For significantly enhanced stiffness, strength, and dimensional stability in highly demanding structural applications.

- Specialized Grades: Including antistatic, conductive, or cleanroom-grade options. For instance, in a semiconductor manufacturing cleanroom, a specialized anti-static PP Rigid Sheet can prevent static discharge damage to sensitive electronic components.

Engaging with a manufacturer that offers robust custom solutions means a partner can provide not just a material, but a tailored component that perfectly integrates into your project, optimizing performance and cost-efficiency. This includes technical consultation, CAD design support, and prototyping services to ensure the final product aligns perfectly with the application's demands.

Manufacturer Comparison and Strategic Partnership

Selecting the right supplier for PP Rigid Sheet is a critical decision for any B2B entity, impacting project timelines, product quality, and long-term cost-efficiency. While many manufacturers produce polypropylene sheets, not all offer the same level of quality, customization, technical support, or commitment to sustainability.

Key Criteria for Manufacturer Evaluation

When comparing manufacturers of PP Rigid Sheet, consider the following:

- Certifications and Compliance: Look for ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product certifications like FDA (for food contact), RoHS (for electronics), or industry-specific standards (e.g., ASTM, DIN). A company with robust certifications demonstrates a commitment to consistent quality and ethical manufacturing.

- Experience and Track Record: A manufacturer with a long history in the industry and a portfolio of successful projects (especially complex, custom solutions) suggests reliability and expertise. Inquiry about their service years and major corporate clients can be insightful.

- Technological Capabilities: Assess their manufacturing equipment (e.g., advanced extrusion lines, precise calendering systems), R&D investment, and ability to produce sheets with tight tolerances, specialized finishes, and complex additive packages.

- Customization and Fabrication Services: Can they provide specific sizes, colors, additives, or even pre-fabricated components (e.g., welding, CNC cutting)? A full-service provider can significantly streamline your supply chain.

- Quality Control and Testing: Beyond certifications, inquire about their internal QC processes, testing methodologies, and traceability of materials.

- Supply Chain Reliability: Evaluate their production capacity, lead times, and ability to handle large or urgent orders. A stable supply chain is crucial for uninterrupted operations.

- Technical Support and Customer Service: Do they offer engineering consultation, material selection guidance, or troubleshooting? Responsive and knowledgeable support is invaluable.

- Sustainability Initiatives: Increasingly important, consider their commitment to recycling, waste reduction, and energy efficiency in their operations.

Example of Manufacturer Capabilities (Generic Comparison)

While specific company names are avoided, this table illustrates typical distinguishing features among different tiers of PP Rigid Sheet suppliers.

| Feature | Tier 1 (Premium/Specialized) | Tier 2 (Volume/Standard) | Tier 3 (Budget/Emerging) |

|---|---|---|---|

| Product Range | Extensive, custom, specialized grades (FR, UV, Antistatic, etc.) | Standard sizes & grades, some common additives | Limited standard sizes & colors, basic grades |

| Quality Certifications | ISO 9001, 14001, FDA, RoHS, multiple industry-specific | ISO 9001, sometimes 14001 | May have basic quality control, fewer formal certs |

| Customization & Fabrication | Full service: Welding, CNC, thermoforming, design support | Basic cutting & some welding, limited design support | Only sheet supply |

| Lead Times (Typical) | 2-4 weeks (custom), shorter for stock | 3-6 weeks | 4-8 weeks, less predictable |

| Technical Support | Dedicated engineers, application specialists | Sales team with basic product knowledge | Minimal or general support |

| Pricing Strategy | Premium for quality, service, customization | Competitive for standard volumes | Cost-focused, potentially inconsistent quality |

A strategic partnership with a reliable manufacturer of PP Rigid Sheet ensures not only the supply of high-quality materials but also access to technical expertise, consistent delivery, and tailored solutions that can significantly enhance your project's success. This approach transforms a simple vendor relationship into a true collaborative partnership focused on long-term value creation.

Application Cases and Success Stories with PP Rigid Sheet

Real-world application cases powerfully illustrate the benefits and performance of PP Rigid Sheet in demanding industrial settings. These examples highlight how tailored solutions using PP Rigid Sheet have provided tangible improvements in efficiency, durability, and cost-effectiveness for various businesses.

Case Study 1: Corrosion Resistance in a Major Chemical Processing Plant

A prominent chemical manufacturing facility faced persistent issues with the corrosion of traditional steel tanks used for storing concentrated sulfuric acid and sodium hydroxide. Frequent repairs and replacements led to significant downtime and high maintenance costs. After extensive consultation and material testing, they opted to line their existing steel tanks with custom-fabricated PP Rigid Sheet panels, and for new installations, to construct entire tanks from self-supporting PP Rigid Sheet. The chosen PP material was a homopolymer grade with excellent chemical resistance. Within the first year, the plant reported a 70% reduction in tank maintenance expenditures and virtually eliminated unexpected downtime caused by corrosion. The project's success was attributed to the precise chemical inertness of the PP Rigid Sheet, which stood up to the aggressive chemicals far better than steel, showcasing its long-term cost savings and operational reliability.

Case Study 2: Enhancing Efficiency in a Water Treatment Facility

A municipal water treatment plant sought to upgrade its filter press system, which used heavy, metal-based plates prone to corrosion and high wear from abrasive solids. The weight of the metal plates also made maintenance cumbersome and inefficient. They collaborated with a PP Rigid Sheet manufacturer to design and supply lightweight, high-strength polypropylene filter plates. The new plates were fabricated from a copolymer PP Rigid Sheet, offering enhanced impact resistance and flexibility. The transition resulted in a 40% reduction in the weight of each filter plate, significantly easing handling and maintenance. Furthermore, the superior chemical resistance of the PP plates to various treatment chemicals and the abrasive nature of the filtered sludge led to a doubling of the lifespan of the filter press components compared to their metal predecessors, thereby boosting overall operational efficiency and reducing replacement frequencies.

Case Study 3: Advanced Packaging for Electronics Manufacturing

An electronics manufacturer required durable, anti-static packaging solutions for shipping sensitive circuit boards and components. Their previous cardboard solutions offered insufficient protection against physical damage and electrostatic discharge (ESD). The solution involved custom-fabricated reusable totes and dividers made from specialized anti-static PP Rigid Sheet. This specific grade of PP Rigid Sheet was engineered to dissipate static charges effectively while offering high rigidity and impact protection. The implementation led to a 95% reduction in product damage due to ESD and physical shock during transit and storage. The reusability of the PP totes also contributed to a 25% reduction in packaging waste over two years, aligning with their corporate sustainability goals.

Case Study 4: Durable Ventilation in Semiconductor Cleanroom

A leading semiconductor fabrication plant needed an overhaul of its cleanroom ventilation system. The existing PVC ducts showed signs of aging and micro-cracking due to continuous exposure to specific processing gases and stringent cleanroom particle requirements. They opted for a comprehensive replacement using fire-retardant and low-outgassing PP Rigid Sheet for all ductwork and plenum components. The high purity and smooth surface finish of the PP Rigid Sheet minimized particle generation, critical for ISO Class 1 cleanroom environments. The superior welding capabilities of PP allowed for seamless, leak-proof construction. Post-installation, the facility reported a noticeable improvement in air quality metrics and a significant reduction in routine maintenance and cleaning cycles for the ventilation system, validating the choice of PP Rigid Sheet for this highly sensitive application.

These diverse case studies underscore the adaptability and effectiveness of PP Rigid Sheet as a material solution. From mitigating severe corrosion challenges to improving operational efficiency and ensuring product safety, its unique properties consistently deliver measurable benefits to industrial clients seeking robust, long-lasting, and cost-effective material solutions.

Trustworthiness: FAQ, Delivery & Warranty for PP Rigid Sheet Solutions

Building trust with B2B clients involves transparent communication regarding product capabilities, supply chain logistics, and post-purchase support. This section addresses common inquiries, clarifies typical delivery processes, and outlines the warranty commitments associated with PP Rigid Sheet products.

Frequently Asked Questions (FAQ) About PP Rigid Sheet

- Q1: What is the maximum operating temperature for PP Rigid Sheet?

- A1: Standard homopolymer PP Rigid Sheet typically has a continuous operating temperature range of -10°C to +100°C. Copolymer grades might tolerate lower temperatures, down to -20°C, while reinforced or specialized grades might offer slight improvements at higher temperatures. It's crucial to consider the specific grade and application for precise temperature limits.

- Q2: Is PP Rigid Sheet resistant to UV degradation?

- A2: Standard PP Rigid Sheet is not inherently UV resistant and will degrade over time with prolonged outdoor exposure. However, UV-stabilized grades are specifically manufactured with additives that provide excellent resistance to UV radiation, making them suitable for outdoor applications such as signage, playground equipment, or agricultural components. Always specify UV resistance if the application involves direct sunlight exposure.

- Q3: Can PP Rigid Sheet be welded or fabricated?

- A3: Absolutely. PP Rigid Sheet is highly thermoplastic and can be easily welded using hot gas welding, extrusion welding, or butt fusion welding techniques, creating strong, homogenous, and leak-proof joints. It can also be readily cut, routed, drilled, thermoformed, and machined, offering significant design flexibility for complex structures.

- Q4: What is the typical lead time for custom PP Rigid Sheet orders?

- A4: Lead times vary depending on the order complexity, quantity, and current production schedule. For standard stock items, delivery can be within 1-2 weeks. For custom sizes, colors, or specialized additive formulations, typical lead times range from 3 to 6 weeks. Larger or highly specialized orders may require longer lead times. We recommend consulting with our sales team for precise lead time estimates based on your specific requirements.

- Q5: Is PP Rigid Sheet recyclable?

- A5: Yes, polypropylene is a fully recyclable thermoplastic, typically identified by the resin code '5'. This makes PP Rigid Sheet an environmentally responsible choice, contributing to reduced landfill waste and resource conservation. Manufacturers often have programs for recycling post-industrial waste.

Delivery Cycle and Logistics

Our commitment to reliable supply chain management ensures efficient delivery of PP Rigid Sheet. Once an order is confirmed, our logistics team coordinates with production to ensure timely dispatch. For standard orders, typical delivery is within 2-3 weeks, depending on destination. For expedited services or international shipments, tailored solutions are available. We utilize robust packaging to protect sheets during transit and can arrange various shipping methods including truck freight, sea freight, or air cargo to meet your project timelines and budget requirements. Our transparent communication keeps you informed at every stage from order placement to final delivery.

Quality Assurance and Warranty Commitment

We stand behind the quality of our PP Rigid Sheet products with comprehensive quality assurance protocols and a clear warranty. All our sheets are manufactured under strict ISO 9001 certified quality management systems, undergoing rigorous inspection and testing to meet published specifications. We offer a standard warranty against manufacturing defects and material non-conformance for a period of typically 1 to 5 years from the date of purchase, depending on the product grade and application. Specific warranty terms will be provided with your quotation. Our dedicated customer support team is always available to address any post-delivery queries, provide technical assistance, or resolve potential issues, ensuring your complete satisfaction and confidence in our PP Rigid Sheet solutions. This commitment to service extends beyond just the product, encompassing full lifecycle support to maximize the value of your investment.

Conclusion: The Enduring Value of PP Rigid Sheet in Modern Industry

The comprehensive analysis of PP Rigid Sheet reinforces its position as a cornerstone material in a wide array of industrial applications. Its unique combination of chemical resistance, lightweight properties, mechanical strength, and ease of fabrication makes it an unparalleled choice for demanding environments where durability and cost-effectiveness are paramount.

From safeguarding critical infrastructure in chemical processing and water treatment facilities to enabling lightweight and efficient designs in automotive and electronics industries, the adaptability of PP Rigid Sheet is truly remarkable. The ongoing advancements in manufacturing processes and material science continue to unlock new potentials, allowing for specialized grades with enhanced UV resistance, flame retardancy, and anti-static properties, thus broadening its scope even further.

For B2B decision-makers, investing in high-quality PP Rigid Sheet from a reputable manufacturer translates into reduced operational costs, extended asset lifecycles, and compliance with increasingly stringent environmental regulations due to its recyclability. The emphasis on robust quality control, adherence to international standards like ISO and ASTM, and a commitment to customer support provides an assurance of trustworthiness and long-term value. As industries continue to evolve, seeking more sustainable, efficient, and resilient material solutions, PP Rigid Sheet will undoubtedly remain a material of choice, driving innovation and performance across the global industrial landscape.

References and Authoritative Citations

- Polypropylene Handbook: A Guide to the Nomenclature, Properties, Structure, Processing and Applications of Polypropylene. Edited by E.P. Moore. Hanser Publications, 1996.

- Standard Specification for Polypropylene Plastic Injection and Extrusion Materials, ASTM D4101. ASTM International.

- Plastics Engineering Handbook. Edited by Donald V. Rosato, Dominick V. Rosato, Matthew Rosato. Springer, 22nd Edition, 2017.

- Modern Plastics Handbook. Edited by Charles A. Harper. McGraw-Hill Professional, 2000.

- Chemical Resistance of Plastics and Elastomers: A Guide to Material Selection. By Industry Council for Plastic Pipe (ICPP).

- Polymer Processing Fundamentals. By Morton M. Denn. Marcel Dekker, 2008.

- Handbook of Plastics, Elastomers, and Composites. By Charles A. Harper. McGraw-Hill, 2002.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025