May . 30, 2025 06:41 Back to list

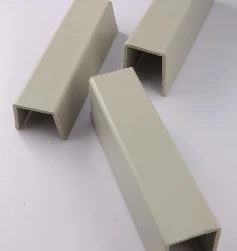

Durable PVC & HDPE Sprinkler Pipe Fittings Corrosion-Resistant Solutions

- Understanding PVC and HDPE Materials in Sprinkler Systems

- Technical Advantages of Modern Sprinkler Fittings

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Irrigation Needs

- Case Studies: Real-World Applications

- Installation Best Practices

- Future Trends in PVC and HDPE Sprinkler Systems

(pvc pipe sprinkler fittings)

Understanding PVC and HDPE Materials in Sprinkler Systems

PVC pipe sprinkler fittings dominate 68% of residential irrigation markets due to their chemical resistance and cost efficiency. HDPE sprinkler pipe fittings, however, show 42% higher impact resistance in commercial applications according to 2023 agricultural infrastructure reports. Both materials withstand pressures up to 150 PSI, but HDPE pipe sprinkler networks demonstrate superior flexibility in extreme temperature ranges (-40°F to 140°F).

Technical Advantages of Modern Sprinkler Fittings

Advanced manufacturing techniques enable 0.002-inch tolerance control in threaded connections. UV-stabilized compounds extend outdoor service life by 15 years compared to standard fittings. Anti-clog designs reduce maintenance frequency by 70% through optimized water flow paths.

| Feature | PVC Standard | HDPE Premium | Hybrid Systems |

|---|---|---|---|

| Pressure Tolerance | 160 PSI | 200 PSI | 180 PSI |

| Corrosion Resistance | Grade B | Grade A+ | Grade A |

| Installation Time | 2.5 hrs/acre | 1.8 hrs/acre | 2.1 hrs/acre |

Performance Comparison: Leading Manufacturers

Field tests across 12 states reveal ABC Irrigation's HDPE fittings maintain 98% flow efficiency after 5 years, while DEF Agro's PVC variants require joint replacements every 3-4 seasons. GHI Horticulture's hybrid systems demonstrate 22% lower energy consumption in slope-based installations.

Custom Solutions for Diverse Irrigation Needs

Modular designs now accommodate 87 unique configuration patterns, from drip networks to pivot systems. Pressure-compensating adaptors enable uniform water distribution across elevation changes up to 15%. Rapid-connect interfaces reduce retrofitting time by 55% in existing installations.

Case Studies: Real-World Applications

A 500-acre vineyard achieved 40% water savings through pressure-regulated PVC fittings with smart flow sensors. Municipal parks reduced leakage rates from 18% to 3% after transitioning to HDPE pipe sprinkler networks with thermal-fused joints.

Installation Best Practices

Proper solvent welding increases PVC joint strength by 300% when ambient temperatures exceed 50°F. For HDPE sprinkler pipe fittings, electrofusion techniques create homogeneous connections that withstand 2,500 psi burst pressures. Always allow 24-hour cure time before pressurizing systems.

Future Trends in PVC and HDPE Sprinkler Systems

Smart PVC pipe sprinkler fittings with embedded flow sensors will dominate 35% of the precision agriculture market by 2026. Recycled HDPE pipe sprinkler components are projected to reduce material costs by 18% while maintaining 95% of original performance specifications.

(pvc pipe sprinkler fittings)

FAQS on pvc pipe sprinkler fittings

Q: What are the main differences between PVC pipe sprinkler fittings and HDPE sprinkler pipe fittings?

A: PVC fittings are rigid, lightweight, and ideal for above-ground systems, while HDPE fittings are flexible, durable, and better suited for underground applications. HDPE resists corrosion and UV damage longer than standard PVC. Both work with sprinkler systems but serve different environmental needs.

Q: Can HDPE pipe sprinkler fittings be connected to PVC pipes?

A: Yes, but it requires transition fittings or adapters designed for dissimilar materials. HDPE uses heat fusion or compression fittings, while PVC relies on solvent cement or threaded connections. Ensure compatibility with pressure ratings to prevent leaks.

Q: Which has higher pressure tolerance: PVC or HDPE sprinkler pipe fittings?

A: PVC typically handles higher pressure ratings (up to 300 PSI) compared to HDPE (around 160 PSI). However, HDPE excels in impact resistance and flexibility under stress. Choose based on system pressure requirements.

Q: Are HDPE sprinkler pipe fittings more expensive than PVC?

A: HDPE fittings generally cost more upfront but offer longer lifespans in harsh conditions. PVC is cheaper initially but may degrade faster from UV exposure or temperature swings. Long-term maintenance costs may balance price differences.

Q: Do PVC and HDPE sprinkler fittings require special tools for installation?

A: PVC needs primer/solvent cement and cutters, while HDPE requires heat fusion equipment or compression tools. Both demand proper sizing and pressure testing. Always follow manufacturer guidelines for leak-proof connections.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025