Aug . 12, 2025 03:00 Back to list

Premium PVC Soft Sheets: Clear, Flexible & Durable

Understanding the Versatility of PVC Soft Sheet in Modern Industries

In today's rapidly evolving industrial landscape, the demand for versatile, durable, and cost-effective materials is paramount. Among these, PVC soft sheet stands out as a fundamental component across a myriad of sectors. Known for its exceptional flexibility, resilience, and adaptability, this material offers solutions for challenges ranging from simple protective coverings to complex industrial applications. Its unique combination of properties, derived from polyvinyl chloride resin and specific plasticizers, enables it to meet stringent technical specifications while remaining economically viable. This comprehensive guide delves into the intricate details of PVC soft sheets, exploring their manufacturing processes, technical specifications, diverse applications, and the strategic advantages they offer to B2B clients seeking reliable material solutions.

The market for flexible PVC products continues to expand, driven by innovation in formulation and processing technologies. This growth is fueled by increasing industrial automation, stricter safety regulations, and a global emphasis on energy efficiency. Manufacturers are continuously researching new ways to enhance the performance characteristics of PVC soft sheet, such as improved UV resistance, enhanced flame retardancy, and better cold-temperature flexibility, making it an indispensable material for future-proof designs and operations. Understanding these trends is crucial for businesses looking to leverage the full potential of this adaptable polymer.

The Advanced Manufacturing Process of PVC Soft Sheet

The production of PVC soft sheet involves a sophisticated manufacturing process, primarily calendering or extrusion, which ensures uniformity and specific material properties. The primary raw material is polyvinyl chloride resin, a thermoplastic polymer. To achieve flexibility and other desired characteristics, plasticizers (like phthalates or non-phthalates), stabilizers (to prevent degradation from heat and UV light), lubricants, and sometimes colorants are blended with the PVC resin. This compound, often in pellet or powder form, is then fed into the processing equipment.

In the calendering process, the compounded PVC material is heated and fed through a series of heated rollers that progressively reduce its thickness and form it into a continuous sheet. The precise control over roller temperature, speed, and gap ensures the desired thickness, width, and surface finish. For thicker sheets or specific profiles, extrusion might be employed, where the molten PVC is pushed through a die. Critical quality control checkpoints are integrated throughout the process, including continuous thickness gauging, visual inspection for defects, and tensile strength testing. Adherence to international standards such as ISO 9001 for quality management and ASTM standards for material testing is paramount, ensuring that the final PVC soft sheet meets rigorous performance requirements for diverse industries like packaging, construction, and general industrial applications.

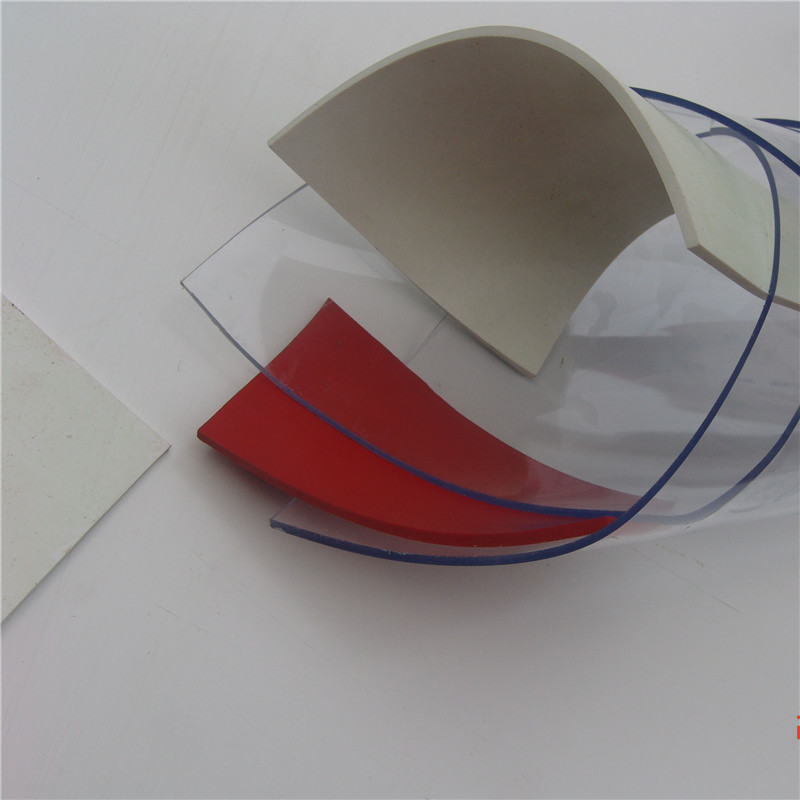

Figure 1: Typical applications showcasing the flexibility and clarity of PVC soft sheet.

Key Technical Parameters and Specifications

Selecting the right PVC soft sheet requires a thorough understanding of its technical parameters. These specifications dictate the material's suitability for specific environments and applications, ensuring optimal performance and longevity. Below is a table outlining typical parameters, though custom specifications are often available based on unique project requirements. Manufacturers often provide detailed technical data sheets conforming to standards like ISO, ASTM, and DIN, which are crucial for engineering and procurement decisions.

Beyond these base parameters, specialized PVC soft sheet variants can offer enhanced properties such as UV stabilization for outdoor applications, anti-static or conductive properties for sensitive electronics manufacturing, flame retardancy (meeting standards like UL94 V-0), and even anti-bacterial surfaces for medical or food processing environments. The applicability of PVC soft sheet in demanding sectors like cleanroom partitioning or industrial curtain walls directly benefits from its robust technical profile and compliance with industry-specific certifications like RoHS or REACH.

Diverse Application Scenarios and Key Advantages

The inherent flexibility, durability, and cost-effectiveness of PVC soft sheet make it an incredibly versatile material with applications spanning numerous industries. Its unique properties provide significant advantages that address specific operational and environmental challenges. For instance, in manufacturing and warehousing facilities, clear PVC soft sheet is widely used for strip curtains or partition walls, significantly reducing energy loss in temperature-controlled environments (e.g., cold storage) and minimizing dust or noise transfer between areas. This direct impact on energy efficiency and operational hygiene translates into tangible cost savings and improved working conditions.

Furthermore, its exceptional chemical resistance makes it ideal for protective linings in tanks or industrial process areas where exposure to corrosive substances is a concern. Unlike metals, PVC soft sheet does not corrode, offering a long-term, low-maintenance solution for chemical containment. Its electrical insulation properties are crucial in applications requiring safety barriers or protective covers for wiring and components. In the packaging sector, its clarity, flexibility, and compliance with certain food-grade standards make it suitable for transparent packaging films, protecting goods while allowing product visibility. Feedback from clients consistently highlights its ease of fabrication, allowing for rapid customization and installation across various complex projects, from flexible doors in high-traffic zones to custom-fabricated protective covers for machinery, underscoring its broad utility and real-world performance.

Strategic Manufacturer Comparison and Tailored Solutions

Choosing the right supplier for PVC soft sheet is a critical decision for any business, directly impacting product quality, project timelines, and overall cost-efficiency. Key factors to consider include the manufacturer's adherence to international quality certifications (e.g., ISO 9001, ISO 14001), their years of experience in the industry, and their commitment to research and development. A reputable manufacturer will not only offer a standard range of products but also provide comprehensive customization solutions, allowing clients to specify precise requirements for thickness, width, color, transparency, and specialized additives.

For instance, a client might require PVC soft sheet with enhanced UV resistance for outdoor applications, anti-static properties for electronic manufacturing environments, or specific flame retardancy ratings for building codes. A leading manufacturer will possess the technical expertise and production capabilities to formulate and produce sheets meeting these exact specifications. They should also be able to provide detailed test reports and compliance certificates (e.g., RoHS, REACH, FDA for specific grades) to ensure product safety and regulatory adherence. By partnering with a manufacturer that emphasizes technical consultation and bespoke production, businesses can ensure they receive PVC soft sheet perfectly tailored to their unique operational needs, thereby optimizing performance and extending service life in demanding industrial settings.

Real-World Case Studies and Implementation Successes

The practical application of PVC soft sheet can best be illustrated through real-world case studies demonstrating its efficacy and adaptability. In one notable instance, a major cold storage facility faced significant energy losses due to frequent door openings. Implementing custom-designed transparent PVC soft sheet strip curtains at all entry points resulted in an estimated 25% reduction in energy consumption for refrigeration over a six-month period. The clarity of the sheets also maintained visibility for forklift operators, enhancing safety.

Another case involved a pharmaceutical manufacturing plant that needed to create sterile, dust-free zones within its existing facility without undergoing extensive structural renovations. By utilizing specialized anti-static and anti-bacterial grade PVC soft sheet for temporary cleanroom partitions, the plant was able to quickly establish controlled environments for sensitive processes, meeting stringent FDA requirements. The ease of installation and ability to conform to existing layouts minimized downtime and capital expenditure. These examples underscore how tailored PVC soft sheet solutions can address complex industrial challenges, providing both immediate operational benefits and long-term cost efficiencies.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of PVC soft sheet?

The lifespan of PVC soft sheet varies significantly based on its specific formulation, application environment, and exposure to elements like UV radiation and extreme temperatures. Generally, indoor applications can see a lifespan of 5-10 years or more, while outdoor applications with UV-stabilized sheets might last 3-7 years. Proper maintenance and cleaning can further extend its service life.

Q2: Is PVC soft sheet recyclable?

Yes, PVC soft sheet is thermoplastic and can be recycled. Many manufacturers and specialized recycling facilities now process PVC waste into new products. This contributes to a circular economy and reduces environmental impact. Look for suppliers who participate in PVC recycling initiatives or offer take-back programs.

Q3: What are the lead times for custom orders of PVC soft sheet?

Lead times for custom PVC soft sheet orders typically depend on the complexity of the customization, order volume, and current production schedules. Standard products might ship within 1-2 weeks, while highly customized or large volume orders could require 4-6 weeks or more. It is always best to consult directly with your supplier for an accurate timeline tailored to your specific needs.

Q4: What kind of warranty or after-sales support is offered?

Reputable manufacturers typically offer a standard product warranty covering material defects and manufacturing flaws for a specified period, often 1-3 years. Beyond this, comprehensive after-sales support includes technical assistance for installation, troubleshooting, and guidance on optimal product use and maintenance. Establishing a relationship with a supplier that offers robust support ensures long-term satisfaction and performance.

Ensuring Seamless Delivery and Unwavering Support

Beyond the intrinsic quality and technical specifications of PVC soft sheet, the reliability of delivery and the robustness of customer support are paramount for B2B operations. A reliable supplier understands the critical nature of timely delivery in maintaining project schedules and operational continuity. They will employ efficient logistics, offer various shipping options, and provide transparent communication regarding order status and estimated arrival times. This commitment to punctuality minimizes disruptions and maximizes client productivity.

Furthermore, comprehensive customer support, encompassing pre-sales consultation and extensive after-sales service, establishes a foundation of trust. This includes expert guidance in selecting the appropriate PVC soft sheet grade for specific applications, assistance with technical inquiries, and prompt resolution of any post-delivery concerns. A strong customer support framework ensures that businesses not only receive high-quality products but also benefit from a partnership that values long-term success and mutual growth.

Conclusion: The Enduring Value of PVC Soft Sheet

PVC soft sheet remains a cornerstone material in industrial and commercial applications due to its unparalleled combination of flexibility, durability, chemical resistance, and cost-effectiveness. From enhancing energy efficiency in cold storage facilities to providing critical protective barriers in manufacturing environments, its versatility continues to drive innovation and provide practical solutions across diverse sectors. As industries evolve, the demand for adaptable and high-performance materials will only increase, solidifying the position of PVC soft sheet as an indispensable component for future-proof engineering and design. Partnering with a knowledgeable and reputable manufacturer ensures access to tailored solutions that meet the most stringent technical and operational requirements.

References

- American Society for Testing and Materials (ASTM) International Standards for Plastics.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- European Chemicals Agency (ECHA) - REACH Regulation Guidelines.

- The Society of Plastics Engineers (SPE) Technical Papers and Journals.

- Modern Plastics Encyclopedia and Industry Handbooks.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025