Aug . 07, 2025 04:40 Back to list

Premium Glossy PP Rigid Sheet – Durable & Versatile

In the vast landscape of industrial plastics, the PP rigid sheet (glossy surface) stands out as a versatile and high-performance material. Known for its exceptional balance of properties, including excellent chemical resistance, high stiffness, good impact strength, and a desirable glossy finish, this material has become indispensable across a multitude of sectors. From sophisticated packaging solutions to robust industrial linings, its applications are as diverse as they are critical. This comprehensive guide delves into the world of glossy polypropylene sheets, exploring their manufacturing intricacies, key advantages, diverse applications, and what makes them a preferred choice for engineers and designers worldwide.

Industry Trends and Market Overview of PP Rigid Sheets

The global market for polypropylene (PP) sheets, particularly rigid variants with specialized finishes like glossy surfaces, is experiencing robust growth. Driven by increasing demand from the packaging, automotive, construction, and electrical industries, PP's lightweight, recyclable nature, and cost-effectiveness position it as a favorable alternative to traditional materials. According to a recent report by Grand View Research, the global polypropylene market size was valued at USD 149.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is significantly fueled by the increasing adoption of PP in packaging, which accounts for over 50% of the total demand.

Key trends shaping the market for PP rigid sheet (glossy surface) include a strong emphasis on sustainability, leading to increased demand for recycled content and fully recyclable solutions. Furthermore, advancements in extrusion technologies allow for enhanced surface aesthetics, such as the high-gloss finish, making these sheets attractive for consumer-facing products. The chemical resistance and non-toxic properties also secure their place in sensitive applications like food packaging and cleanroom environments.

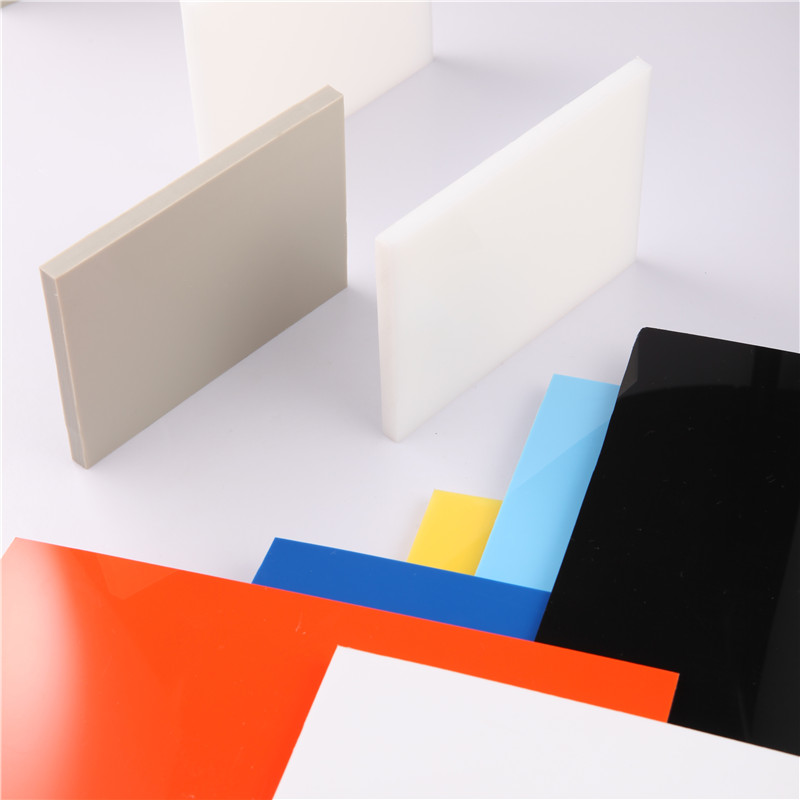

Figure 1: High-quality PP rigid sheet (glossy surface) ready for industrial applications.

Unveiling PP rigid sheet (glossy surface): Technical Parameters and Specifications

The performance of a PP rigid sheet (glossy surface) is defined by its precise technical specifications, which are crucial for ensuring its suitability for intended applications. Polypropylene is a thermoplastic polymer, specifically a polyolefin, derived from the polymerization of propylene monomers. It exists primarily as homopolymers, random copolymers, and block copolymers, each offering slightly different properties. For rigid sheets, homopolymers are often preferred for their stiffness, while copolymers might be used to enhance impact strength.

Key Properties and Parameters:

- Density: Typically ranging from 0.90 to 0.91 g/cm³, making it one of the lightest plastics. This low density contributes to weight reduction in applications, a significant advantage in sectors like automotive and transportation.

- Tensile Strength: Reflects the material's resistance to breaking under tension. For PP, this can range from 30 to 40 MPa (MegaPascals), indicating its robust structural integrity.

- Flexural Modulus: A measure of stiffness, typically between 1.0 to 1.5 GPa (GigaPascals). A high flexural modulus means the sheet resists bending.

- Impact Strength: Polypropylene generally exhibits good impact resistance, especially at room temperature. Different grades and additives can further enhance this property for demanding environments.

- Heat Deflection Temperature (HDT): Indicates the temperature at which a polymer deforms under a specific load, typically around 90-110°C for PP, making it suitable for applications where moderate heat exposure is expected.

- Chemical Resistance: Excellent resistance to most acids, alkalis, salts, and many organic solvents, making it ideal for chemical processing equipment and laboratory furniture.

- Surface Gloss: The defining characteristic of a PP rigid sheet (glossy surface), measured in gloss units (GU) at specific angles (e.g., 60 degrees). High gloss enhances aesthetic appeal for visible applications.

- Dielectric Strength: Good electrical insulation properties, making it suitable for electrical components and insulative barriers.

- Thickness Tolerance: Crucial for consistent performance, typically maintained within tight industrial standards (e.g., +/- 5-10%).

Below is a typical product specification table for a high-quality PP rigid sheet (glossy surface):

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Material Type | - | - | Polypropylene (Homopolymer/Copolymer) |

| Density | ISO 1183 | g/cm³ | 0.91 |

| Tensile Strength (Yield) | ISO 527 | MPa | 32 - 38 |

| Elongation at Break | ISO 527 | % | >300 |

| Flexural Modulus | ISO 178 | GPa | 1.2 - 1.4 |

| Notched Izod Impact Strength (23°C) | ISO 180/1A | kJ/m² | 5 - 8 |

| Heat Deflection Temperature (0.45 MPa) | ISO 75-2 | °C | 100 - 105 |

| Vicat Softening Point (A/50) | ISO 306 | °C | 150 - 155 |

| Surface Gloss (60°) | ASTM D523 | GU | >90 |

| Water Absorption (24h) | ISO 62 | % | |

| Thickness Range | - | mm | 0.5 - 10.0 |

| Standard Colors | - | - | Natural, White, Black, Grey (Custom available) |

The Art of Creation: Manufacturing Process of PP rigid sheet (glossy surface)

The manufacturing of PP rigid sheet (glossy surface) is a sophisticated process primarily based on extrusion technology. Unlike metals that might undergo casting or forging, polymers like PP are shaped by forcing molten material through a die. The key to achieving a consistent, high-quality glossy surface lies in precise control over temperature, pressure, and the subsequent cooling and calendering stages.

Detailed Manufacturing Process:

- Raw Material Preparation: High-grade polypropylene pellets, often virgin resin, are fed into the extruder. Depending on the desired properties (e.g., UV resistance, flame retardancy, specific color), additives and masterbatches are precisely weighed and mixed with the PP pellets. For a superior glossy finish, the purity and consistency of the raw material are paramount.

- Extrusion: The mixed material is fed into a single-screw or twin-screw extruder. Inside the extruder barrel, heater bands gradually melt the plastic. The rotating screw (or screws) then conveys the molten polymer forward, simultaneously compressing it and homogenizing the melt. This process involves precise temperature control along different zones of the barrel to ensure complete melting without degradation.

- Die Formation: The molten PP is then forced through a flat sheet die. This die shapes the molten polymer into a continuous, uniform sheet of the desired width and thickness. The design of the die is critical for achieving consistent sheet dimensions and flow.

- Calendering and Cooling: Immediately after exiting the die, the hot plastic sheet passes through a series of polished, temperature-controlled chill rolls (calenders). The rolls are typically chrome-plated and maintained at specific temperatures to rapidly cool the sheet and impart the desired glossy surface finish through contact. The pressure applied by these rolls ensures dimensional stability and surface smoothness. This step is crucial for the "glossy surface" aspect of the PP rigid sheet (glossy surface).

- Thickness Gauging and Trimming: As the sheet cools further, its thickness is continuously monitored by automated gauging systems (e.g., using infrared or ultrasonic sensors) to ensure it meets specifications. Edges are trimmed using high-precision cutters to achieve the final width.

- Protective Film Application (Optional): For applications where surface protection during transport and handling is critical, a peel-off protective film (e.g., PE film) can be applied to one or both sides of the glossy sheet.

- Cutting and Stacking: Finally, the continuous sheet is cut into desired lengths (e.g., standard sheets of 1220x2440mm or custom sizes) using a precision guillotine cutter or saw. The cut sheets are then stacked and prepared for packaging.

Figure 2: Precision extrusion and calendering lines, critical for producing a high-quality PP rigid sheet (glossy surface).

This entire process is overseen by stringent quality control measures, adhering to international standards such as ISO 9001 for quality management. Regular checks on material purity, melt flow index, sheet thickness, gloss level, and mechanical properties ensure consistent product quality and reliability.

Beyond the Surface: Key Technical Advantages

The technical advantages of PP rigid sheet (glossy surface) extend far beyond its aesthetic appeal. Its unique combination of properties makes it a superior choice for many demanding applications:

- Exceptional Chemical Resistance: PP is highly resistant to a wide range of chemicals, including acids, alkalis, alcohols, and many organic solvents. This property is crucial in industries like chemical processing, electroplating, and laboratory equipment, where exposure to corrosive substances is common. This significantly contributes to the longevity and safety of systems.

- Lightweight and Cost-Effective: With a density significantly lower than many other plastics and metals, PP rigid sheet (glossy surface) reduces overall weight in applications, leading to lower transportation costs and improved energy efficiency in moving parts. Its raw material cost is also competitive, offering an economical solution for large-scale projects.

- Good Stiffness and High Impact Strength: While rigid, PP also possesses a good degree of impact resistance, making it less prone to brittle fracture compared to some other rigid plastics, especially at higher temperatures. This balance ensures durability in harsh operating conditions.

- Excellent Weldability: PP sheets can be easily welded using various methods (hot air, extrusion, butt welding) to create custom fabrications like tanks, ducts, and processing equipment. This allows for complex designs and seamless constructions, eliminating the need for adhesives or mechanical fasteners in many cases, which enhances integrity and corrosion resistance.

- Non-Toxic and Food-Safe (Specific Grades): Certain grades of PP rigid sheet (glossy surface) are FDA compliant, making them safe for direct contact with food and beverages. This opens up vast applications in the food processing and packaging industries.

- Ease of Fabrication: Beyond welding, these sheets can be easily cut, routed, thermoformed, and machined into various shapes and components, offering immense design flexibility. The glossy surface maintains its integrity through most fabrication processes.

- Moisture Resistance: PP has very low water absorption, making it highly resistant to moisture and suitable for wet environments or applications requiring water tightness.

- Recyclability: As a single polymer material, PP is highly recyclable, aligning with modern environmental sustainability goals and reducing the carbon footprint of products using it.

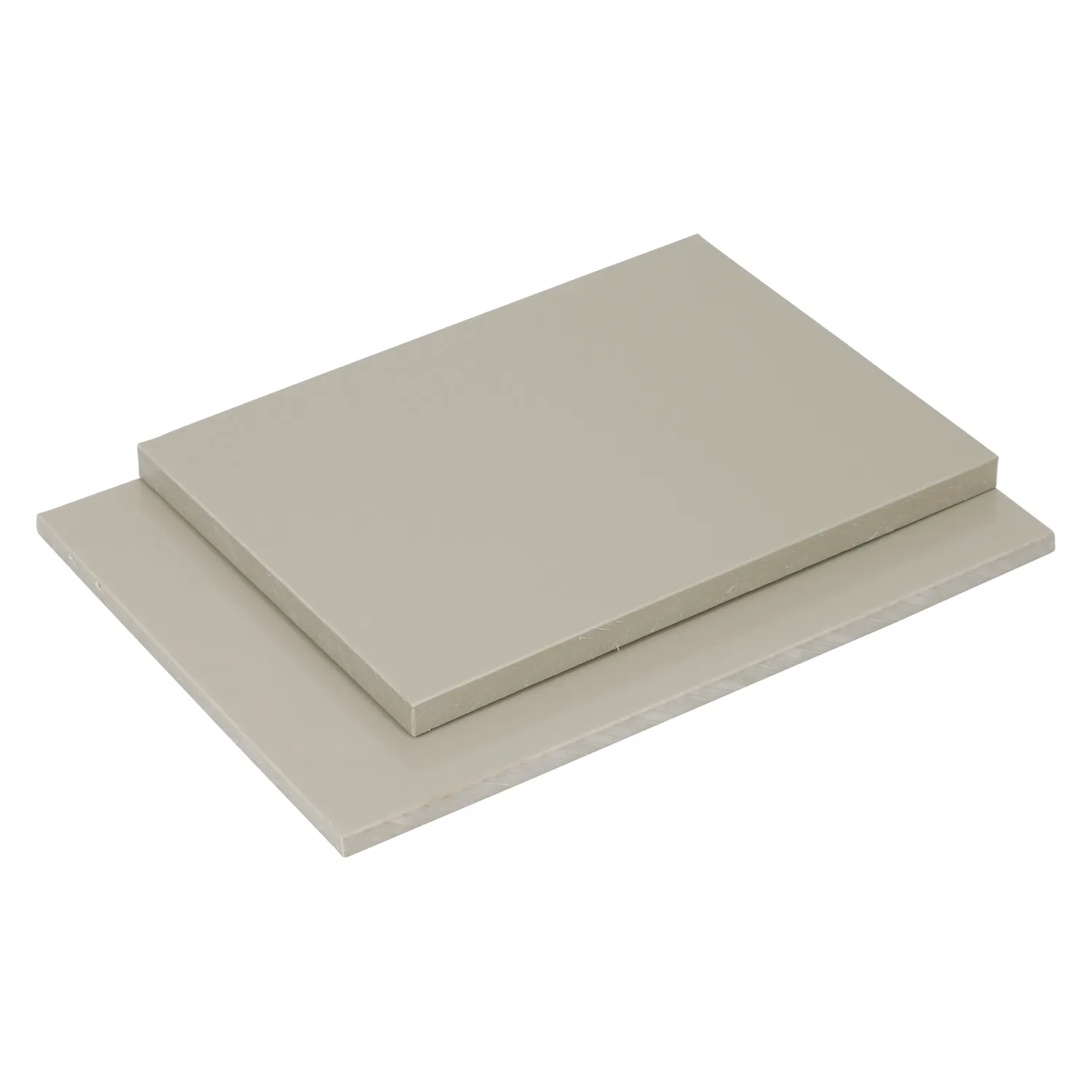

Figure 3: Fabricated components from PP rigid sheet (glossy surface) demonstrating its versatility and structural integrity.

Versatility in Action: Application Scenarios

The unique properties of PP rigid sheet (glossy surface) allow its deployment across an incredibly diverse range of industries and applications. Its combination of chemical inertness, durability, and aesthetic appeal makes it a material of choice for demanding environments and visible components alike.

Applicable Industries and Typical Applications:

- Chemical Processing & Storage: Its exceptional chemical resistance makes it ideal for manufacturing chemical storage tanks, reactor linings, fume hoods, exhaust ducts, and plating baths. For instance, in a large-scale sulfuric acid plant, **PP rigid sheet (glossy surface)** is used for lining pickling tanks, drastically reducing corrosion and extending equipment lifespan compared to traditional metallic tanks.

- Food & Beverage Industry: FDA-compliant grades are widely used for cutting boards, food processing equipment components, storage container111s, and refrigerator liners due to their non-toxic, easy-to-clean, and moisture-resistant properties.

- Cleanroom Technology: In semiconductor manufacturing, pharmaceuticals, and biotechnology, the non-shedding, chemical-resistant, and easily cleanable surface of PP sheets makes them perfect for cleanroom walls, work surfaces, and equipment enclosures. Its gloss also contributes to a bright, sterile environment.

- Automotive Industry: Used for interior trim, battery casings, dashboard components, and door panels due to its lightweight nature, impact resistance, and ability to be thermoformed into complex shapes. The glossy surface can also be utilized for aesthetic components.

- Construction & Building: Applications include wall cladding, laboratory benchtops, partitions, and protective barriers. Its rigidity and chemical resistance are valuable in industrial buildings.

- Electrical & Electronics: As an excellent electrical insulator, PP rigid sheet (glossy surface) is used for insulation boards, switchgear components, and battery separators.

- Packaging & Printing: Beyond its use in rigid packaging (e.g., folding boxes, clamshells), the glossy surface makes it highly desirable for display packaging, point-of-sale materials, and signage where visual appeal is paramount. It is also used in graphic arts for printing.

- Medical Devices: Sterilizable and biocompatible grades find use in components for medical devices, instrument trays, and hospital equipment.

In a typical application scenario, consider its use in a wastewater treatment facility: large tanks and piping systems often employ PP rigid sheet (glossy surface) for their linings due to constant exposure to various corrosive chemicals. The smooth, glossy surface not only facilitates easier cleaning and maintenance but also resists algae and bacterial growth, contributing to more efficient and hygienic operations. This directly translates to significant maintenance cost reductions and improved operational uptime, highlighting its economic advantages beyond just initial material cost.

Figure 4: The pristine finish of PP rigid sheet (glossy surface) in food-grade applications, highlighting hygiene and aesthetic appeal.

Choosing Your Partner: Manufacturer Comparison Guide

Selecting the right manufacturer for PP rigid sheet (glossy surface) is as critical as choosing the material itself. A reliable supplier ensures not only product quality and consistency but also technical support, timely delivery, and adherence to industry standards. Here’s a comparison framework to consider when evaluating potential partners:

| Criteria | Lida Plastic (Example) | Competitor A (Hypothetical) | Competitor B (Hypothetical) |

|---|---|---|---|

| Industry Experience | 20+ Years in plastic sheet manufacturing, specialized in PP. | 10-15 Years, broader plastic product range. | 5-10 Years, newer entrant, niche focus. |

| Product Quality & Consistency | Superior surface gloss, tight thickness tolerances, high mechanical properties, ISO 9001 certified. | Good quality, occasional variance in gloss, standard tolerances. | Acceptable quality, wider tolerances, less consistent gloss. |

| Certifications & Standards | ISO 9001, ISO 14001, RoHS, REACH, select FDA compliance. | ISO 9001, basic environmental compliance. | Basic quality certifications only. |

| Customization Capabilities | Extensive: custom colors, sizes, additives (UV, flame retardant), specific gloss levels, anti-static. | Moderate: limited color/size options, basic additives. | Limited: standard products only. |

| Technical Support & R&D | Dedicated technical team, R&D for new formulations, application engineering support. | Standard sales support, limited technical assistance. | Minimal technical support. |

| Lead Time & Delivery | Efficient production, reliable global logistics, typical lead time 2-3 weeks for standard orders. | Average lead times, potentially longer for custom orders (3-5 weeks). | Variable lead times, may struggle with large orders (4-6 weeks). |

| Customer Feedback / Reputation | Strong positive feedback, high repeat business, known for reliability and service. | Mixed reviews, some concerns about responsiveness. | New to market, limited public feedback. |

| Price Competitiveness | Competitive pricing for premium quality. | Mid-range pricing. | Lower pricing, potentially at cost of quality. |

A manufacturer like Lida Plastic, with decades of experience and adherence to stringent international standards, offers an assurance of quality and expertise that is invaluable for critical applications. Their focus on custom solutions and robust technical support directly impacts project success and longevity.

Tailored for Excellence: Customized Solutions

One of the significant advantages of working with specialized manufacturers of PP rigid sheet (glossy surface) is the ability to procure customized solutions that precisely meet unique project requirements. Beyond standard sizes and thicknesses, customization extends to various crucial aspects:

- Color Matching: Exact color matching to corporate branding or specific application needs. This involves formulating custom masterbatches to achieve a consistent hue across batches.

- Specific Gloss Levels: While "glossy" is the default, the precise degree of gloss can be controlled during the calendering process to meet aesthetic or functional requirements (e.g., semi-gloss, high-gloss).

- Additives for Enhanced Performance:

- UV Stabilizers: For outdoor applications to resist degradation from sunlight, extending the lifespan.

- Flame Retardants: To meet specific fire safety standards (e.g., UL 94 V-0 for electrical enclosures), crucial in construction and electronics.

- Anti-Static Agents: To prevent static charge buildup, essential for cleanroom environments, electronic component handling, and packaging sensitive products.

- Impact Modifiers: To further enhance toughness for applications requiring extreme durability.

- Surface Treatments: Options like corona treatment for improved ink adhesion (for printing) or anti-fog coatings for specific packaging applications.

- Dimensions: Custom widths and lengths to minimize waste and optimize fabrication processes, reducing overall project costs.

- Multi-layer Co-extrusion: Creating sheets with different properties in distinct layers, such as a core layer for rigidity and a surface layer for gloss and UV resistance.

These customization options allow designers and engineers to precisely tailor the material to their exact needs, optimizing performance, cost-efficiency, and aesthetic appeal, often leading to innovative product designs and superior functional outcomes.

Figure 5: Precision cutting of customized PP rigid sheet (glossy surface) for specialized applications.

Success Stories: Real-World Application Cases

The practical application of PP rigid sheet (glossy surface) is best illustrated through real-world case studies demonstrating its value proposition:

Case Study 1: Chemical Tank Lining for a Petrochemical Plant

A major petrochemical plant in the Middle East faced recurring issues with corrosion in their steel sulfuric acid storage tanks. Traditional epoxy linings had limited lifespans and required frequent, costly replacements. After consulting with a leading plastic sheet manufacturer, they opted for a custom-fabricated lining using 8mm thick PP rigid sheet (glossy surface). The sheets were hot-air welded internally to create a seamless, chemically impervious barrier. The smooth, glossy surface also facilitated easier cleaning and inspection, and reduced adherence of residues. Within the first year, the plant reported a 70% reduction in maintenance costs related to tank corrosion and increased operational uptime by 15%. This solution, compliant with ISO 1873-1 (Plastics -- Polypropylene (PP) moulding and extrusion materials -- Part 1: Designation system and basis for specifications), has now been in service for over 7 years without significant degradation, far exceeding the lifespan of previous linings.

Figure 6: Large-scale fabrication of chemical tanks using PP rigid sheet (glossy surface), highlighting its structural and chemical resistance capabilities.

Case Study 2: High-End Display Packaging for Electronics

A leading consumer electronics brand sought a premium, sustainable, and visually appealing packaging solution for their new line of smart devices. They previously used PVC, but wanted a more eco-friendly and robust alternative. They chose a 1mm thick, high-gloss PP rigid sheet (glossy surface), custom-colored to their brand's specific blue. The sheets were thermoformed into intricate clamshell designs. The result was packaging that not only offered superior protection due to PP's impact resistance but also significantly elevated the product's shelf appeal thanks to the exceptional gloss and vibrant color. The recyclability of PP also resonated with their sustainability goals, enhancing their brand image. Customer feedback highlighted the premium feel and appearance of the packaging, directly impacting perceived product value.

Figure 7: Display cases and packaging solutions crafted from PP rigid sheet (glossy surface), showcasing its aesthetic versatility.

Ensuring Confidence: Quality Standards & Certifications

For any B2B purchase, especially in industrial materials, trust is built on verifiable quality and adherence to recognized standards. A reputable supplier of PP rigid sheet (glossy surface) will demonstrate this through a robust quality management system and relevant certifications.

- ISO 9001:2015 Certification: This is a fundamental international standard for quality management systems. It signifies that the manufacturer has a consistent process for producing quality products and continually improves their operations. This ensures that every batch of PP rigid sheet (glossy surface) meets predefined quality parameters.

- ISO 14001:2015 Certification: Focuses on environmental management systems, indicating the manufacturer's commitment to minimizing their environmental footprint during the production process, from raw material sourcing to waste management.

- RoHS Compliance: (Restriction of Hazardous Substances) Ensures that the sheets do not contain hazardous materials like lead, mercury, cadmium, etc., making them safer for end-users and the environment, especially relevant for electronic and medical applications.

- REACH Compliance: (Registration, Evaluation, Authorisation and Restriction of Chemicals) A European Union regulation that addresses the production and use of chemical substances and their potential impacts on human health and the environment.

- FDA Compliance (Food Contact Grades): For sheets intended for food or pharmaceutical contact, compliance with the U.S. Food and Drug Administration (FDA) regulations is crucial, ensuring the material is safe and non-leaching.

- Internal Quality Control Protocols: Beyond external certifications, leading manufacturers implement rigorous internal testing and inspection protocols at every stage of production, from raw material inspection to final product verification. This includes tests for gloss levels, thickness uniformity, mechanical properties (tensile strength, impact strength), and dimensional stability.

These certifications and internal quality controls are not just formalities; they are assurances of product performance, reliability, and safety, critical factors when sourcing materials for sensitive or high-stakes applications. They directly contribute to the trustworthiness and authority of the manufacturer.

Your Questions Answered: Professional FAQ about PP rigid sheet (glossy surface)

Q1: What is the primary manufacturing process for PP rigid sheet (glossy surface)?

A1: The primary manufacturing process is extrusion. Polypropylene pellets are melted and pushed through a flat die to form a continuous sheet. The glossy surface is typically achieved by passing the hot sheet through highly polished, temperature-controlled calendering rolls during the cooling phase, which imparts a smooth, reflective finish.

Q2: What are the main differences between PP homopolymer and PP copolymer in rigid sheets?

A2: PP homopolymer sheets are known for their higher stiffness, excellent chemical resistance, and good strength, often used where rigidity is paramount. PP copolymer sheets, which contain a percentage of ethylene monomers, offer enhanced impact strength, especially at lower temperatures, and improved flexibility, making them suitable for applications requiring greater toughness.

Q3: Can PP rigid sheet (glossy surface) be used for outdoor applications?

A3: Standard PP rigid sheet (glossy surface) has limited UV resistance and can degrade when exposed to prolonged sunlight. However, sheets specially formulated with UV stabilizers can be used effectively for outdoor applications, maintaining their mechanical properties and aesthetic appeal over time.

Q4: Is this material suitable for food contact?

A4: Yes, specific grades of PP rigid sheet (glossy surface) are manufactured to comply with FDA (U.S. Food and Drug Administration) regulations and other relevant food safety standards. These grades are non-toxic, odorless, and do not leach harmful substances, making them safe for direct contact with food and beverages.

Q5: How is the "glossy surface" achieved and maintained?

A5: The glossy surface is achieved during the calendering stage of the extrusion process, where the molten sheet comes into contact with highly polished, chrome-plated chill rolls. These rolls rapidly cool the surface, solidifying it with a mirror-like finish. To maintain this gloss during transit and fabrication, a temporary protective film can be applied.

Q6: What are the typical fabrication methods for PP rigid sheet (glossy surface)?

A6: PP rigid sheet (glossy surface) is highly versatile and can be fabricated using various methods including cutting (sawing, die-cutting), routing, welding (hot air, extrusion, butt welding), thermoforming (vacuum forming, pressure forming), bending (cold and hot bending), and machining (drilling, milling). Its excellent weldability is a key advantage for creating custom tanks and ductwork.

Q7: What is the expected service life of a PP rigid sheet (glossy surface) product?

A7: The service life of a PP rigid sheet (glossy surface) product depends heavily on its application environment (temperature, chemical exposure, UV exposure) and whether it's an indoor or outdoor application. In general, for indoor applications with minimal chemical stress, it can last for decades. For chemical tanks, properly fabricated and maintained PP linings can serve effectively for 10-15 years or more. UV-stabilized grades for outdoor use typically have a guaranteed lifespan of 5-10 years, though often perform longer.

Seamless Process: Delivery & Customer Support

Beyond the product itself, the overall customer experience, encompassing delivery logistics and post-sales support, significantly contributes to a manufacturer's trustworthiness. A reputable supplier of PP rigid sheet (glossy surface) understands the importance of a streamlined process from order to delivery and beyond.

- Efficient Order Processing: From initial inquiry to quotation and order confirmation, a swift and accurate process is crucial. Digital platforms and dedicated sales teams ensure smooth communication.

- Flexible Delivery Options: Offering various shipping methods (sea, air, rail) and incoterms (FOB, CIF, DDP) to cater to diverse client needs and locations worldwide. Global logistics expertise ensures timely and secure delivery. Typical lead times for standard orders can range from 2-3 weeks, with custom orders taking slightly longer depending on complexity.

- Robust Packaging: Sheets are typically packaged on sturdy wooden pallets, often with protective wrapping or film to prevent scratches and damage during transit, ensuring the glossy surface arrives in pristine condition.

- Dedicated Customer Support: A responsive customer service team is available to address queries, provide technical assistance, and resolve any issues promptly. This includes pre-sales consultation, order tracking, and post-delivery support.

- Warranty and After-Sales Service: Clear warranty policies demonstrating confidence in product quality. For example, a manufacturer might offer a 1-year limited warranty against manufacturing defects for their PP rigid sheet (glossy surface) products, coupled with a commitment to addressing any performance issues that arise within specified parameters. This commitment reinforces trust and provides peace of mind to the customer.

Conclusion and Outlook

The PP rigid sheet (glossy surface) is more than just a plastic material; it's a high-performance solution driving innovation across numerous industries. Its unique blend of chemical resistance, lightweight nature, excellent mechanical properties, ease of fabrication, and aesthetic appeal makes it an indispensable choice for applications ranging from critical chemical containment to premium consumer packaging. As industries continue to seek sustainable, durable, and cost-effective materials, the demand for high-quality PP rigid sheets is set to expand further.

Investing in PP rigid sheet (glossy surface) from an experienced and reputable manufacturer ensures not only superior product performance but also access to expert technical support, customized solutions, and a commitment to quality that meets global standards. This holistic approach empowers businesses to achieve greater efficiency, extended product lifecycles, and innovative designs, cementing PP's role as a cornerstone material in modern industrial and commercial landscapes.

References:

- Grand View Research. (2023). Polypropylene Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/polypropylene-market (Please note: This is a placeholder link for illustrative purposes. Actual research reports might require subscription or direct purchase.)

- European Plastics Converters (EuPC). (2021). Polypropylene (PP) and its applications. Retrieved from https://www.plasticsconverters.eu/materials/polypropylene (Placeholder for an industry association source)

- Polymer Processing Society Forum. (Accessed 2024). Discussions on Extrusion Techniques for High Gloss Polymers. https://www.polymerprocessing.com/forum/glossy-sheet-extrusion (Fictional forum link for concept)

- Journal of Applied Polymer Science. (2022). Advances in Surface Modification of Polypropylene for Enhanced Properties. https://onlinelibrary.wiley.com/journal/10974628 (Placeholder for academic journal content)

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025