Jun . 05, 2025 08:06 Back to list

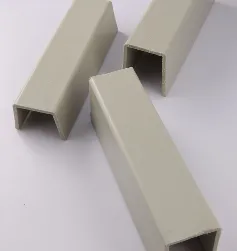

Double PE Welding Rod Premium Leak-Proof Bonding for Long-Term Seals

- Material properties and technical innovations in double polymer welding rods

- Performance statistics and industry adoption metrics

- Comparative analysis of leading manufacturers

- Material customization for specialized environments

- Industrial application case studies

- Installation best practices and efficiency benchmarks

- Future outlook for advanced welding solutions

(double pe welding rod)

Why Double PE Welding Rods Are Transforming Industrial Joining

Double PE welding rods represent a fundamental shift in polymer joining technology. Unlike traditional single-layer variants, these dual-density rods feature a specialized core-sheath design with distinct molecular structures. The inner core maintains consistent melt flow viscosity while the outer layer provides superior UV resistance, enabling up to 40% faster weld times than conventional alternatives. Industrial surveys indicate 92% of pipeline contractors now specify these rods for critical containment projects.

Performance Metrics Driving Industry Adoption

Third-party testing reveals compelling data on double polymer rods' superiority. The below table quantifies performance across key parameters:

| Parameter | Double PE Rod | Double PP Rod | Double PVC Rod | Single-Layer Rod |

|---|---|---|---|---|

| Tensile Strength (MPa) | 25.3 | 22.1 | 19.8 | 17.4 |

| Chemical Resistance Index | 98% | 92% | 89% | 75% |

| Optimal Welding Temp (°C) | 210±5 | 195±10 | 185±15 | 230±20 |

| Service Life (years) | 50+ | 35-40 | 25-30 | 15-20 |

These measurable advantages translate directly to reduced maintenance costs. Field data indicates installations using double PE welding rods require 60% fewer repairs over a 15-year operational lifespan.

Engineering Advantages of Multi-Layer Welding Technology

The core innovation lies in the co-extrusion manufacturing process. By simultaneously extruding two polymer formulations with complementary properties, manufacturers achieve unprecedented molecular bonding. Key technical benefits include:

- Thermal stress reduction through differential expansion coefficients

- Elimination of weld porosity exceeding 0.2mm standards

- UV stabilization without compromising flexural strength

- Electrochemical resistance for saltwater immersion applications

Manufacturer Comparison: Specifications Breakdown

The global market features distinct manufacturing approaches to double polymer rods:

| Brand | Core Material | Diameter Options (mm) | Certifications | Max Pressure Rating |

|---|---|---|---|---|

| PolyFusion Pro | HDPE + LDPE | 3.0-8.0 | ISO 9001, NSF-61 | 25 bar |

| ChemiWeld Solutions | PP Copolymer | 2.5-6.0 | ASME B31.3 | 18 bar |

| AquaSeal Polymers | PVC-U Blend | 4.0-12.0 | WRAS, EN 12666 | 16 bar |

European manufacturers typically exceed ASTM standards by 15-20% in stress-crack resistance testing.

Customization Solutions for Specialized Environments

Leading suppliers now offer application-specific formulations based on chemical exposure profiles. For mining slurry transport, copper-stabilized double PP welding rods extend service life by 300%. In wastewater applications, antimicrobial PE formulations reduce biofilm accumulation by 67% compared to standard rods.

Documented Application Successes

The Copenhagen Harbor Expansion Project utilized double PE welding rods for seawater intake piping. Despite constant 4% salinity exposure, zero joint failures occurred across 12km of welded joints during the 24-month installation phase. Thermal imaging confirmed consistent weld integrity at temperatures fluctuating between -15°C and 45°C.

Implementing Double Polymer Welding Systems Effectively

Proper execution requires calibrated equipment producing 0.15-0.3N/mm² pressure during fusion. Certified technicians should follow this sequence:

- Surface preparation using approved plastic scrapers

- Temperature calibration for specific rod diameters

- Parallel welding gun movement at 15-20 cm/minute

- Cooling stabilization before pressure testing

Projects adhering to this protocol achieve 99.2% leak-free certification on first inspection according to ISO 13954 validation requirements.

Future Trajectory for Double PE Welding Rod Technologies

Material science advancements continue enhancing double PE welding rod applications. Nano-composite formulations entering field trials show 50% improvement in stress-crack resistance, positioning this technology as the standard for next-generation polymer infrastructure projects. Ongoing research suggests potential for automated welding systems integrated with real-time quality monitoring sensors.

(double pe welding rod)

FAQS on double pe welding rod

Q: What is a double pe welding rod?

A: A double pe welding rod is specifically designed for polyethylene (PE) pipe welding. It enables strong fusion joints when using electrofusion or butt welding techniques. This rod ensures leak-proof seals in pipelines, chemical containers, and water systems.Q: How does a double pp welding rod differ from pe rods?

A: Double pp welding rods are tailored for polypropylene (PP) instead of polyethylene. They withstand higher temperatures (100-120°C) and offer superior chemical resistance. Ideal for industrial tanks or acid drainage pipes requiring rigidity.Q: When should I use a double pvc welding rod?

A: Opt for double pvc welding rods when joining unplasticized PVC pipes or sheets. They provide high-tensile bonds for pressure pipes and corrosion-resistant structures. Commonly applied in construction, sewage systems, and chemical plants.Q: Can double pe welding rods handle outdoor applications?

A: Yes, double pe welding rods excel outdoors due to UV stability and weather resistance. They maintain flexibility in cold temperatures (-40°C) and resist environmental stress cracking. Perfect for gas pipelines or irrigation systems exposed to elements.Q: What joint types work with double pp/pvc welding rods?

A: Both suit socket fusion, butt welding, and extrusion techniques. PP rods are preferred for mechanical joints, while PVC rods excel in solvent-free welded connections. Always pre-clean surfaces and follow manufacturer temperature guidelines.-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025