Jul . 04, 2025 10:15 Back to list

High Transparency PVC Clear Sheet Super Transparency PVC Sheets & HDPE Cutting Board Supplier

- Introduction to high transparency PVC clear sheet and related materials

- Technical advantages and properties of super transparency PVC clear sheet

- Comparative study: high transparency PVC clear sheet vs high density polyethylene cutting board

- Customization options in high transparency PVC clear sheet production

- Application case studies across various industries

- Key considerations when choosing PVC materials

- Conclusion: The future of high transparency PVC clear sheet in modern manufacturing

(high transparency pvc clear sheet)

Introduction to High Transparency PVC Clear Sheet in Modern Manufacturing

The need for versatile and durable transparent materials has driven significant innovations in the plastics and polymers industry. Among the most notable of these innovations is the development of high transparency PVC clear sheet, an industry standard for clarity and performance. Related products, including super transparency PVC clear sheet and high density polyethylene cutting board, serve specific roles in commercial and industrial applications. As manufacturing demands higher transparency, chemical stability, and customizability, PVC sheets have become a preferred choice across sectors such as construction, packaging, electronics, and medical equipment.

Interest in transparent sheets has surged. Data insights from MarketsandMarkets indicate the global transparent plastics market is projected to reach USD 159.2 billion by 2028, growing at a CAGR of 6.1% from 2023 to 2028. This growth is primarily driven by the rise in industrial applications and the need for materials that combine optical clarity, UV stability, and resistance to chemicals. High transparency PVC clear sheets, in particular, meet stringent international quality standards, often exceeding 90% light transmittance while maintaining mechanical robustness and processability.

Technical Advantages and Properties of Super Transparency PVC Clear Sheet

The super transparency PVC clear sheet stands out due to its unique set of physical and chemical attributes. When compared to standard transparent plastics, it showcases remarkable optical clarity, with some products achieving up to 92% total light transmission. Such high transparency is crucial for applications where visual aesthetics or visibility of underlying surfaces is a priority, such as point-of-sale displays, instrumentation panels, and protective barriers.

In terms of mechanical strength, the super transparency PVC clear sheet exhibits high tensile and impact strength, with an average tensile strength of 52 MPa. Its inherent chemical stability means these sheets resist yellowing, weathering, and harmful UV exposure for years, retaining their clarity and mechanical properties. Additionally, they are flame retardant, self-extinguishing according to UL94 V-0 standard, and safe for use in public and high-traffic environments.

The advanced production technology of super transparency PVC clear sheets ensures consistent sheet thickness (typically 0.3mm to 10mm), flawless surface finish, and compatibility with printing, cutting, and thermoforming processes. This versatility opens doors to a wide range of downstream customizations and end uses.

Comparative Study: High Transparency PVC Clear Sheet vs High Density Polyethylene Cutting Board

While both high transparency PVC clear sheet and high density polyethylene (HDPE) cutting boards are polymers with notable industrial applications, their fundamental characteristics influence their ideal uses. Below is a direct comparative analysis between these materials based on core technical metrics and user demands:

| Property | High Transparency PVC Clear Sheet | High Density Polyethylene Cutting Board |

|---|---|---|

| Light Transmittance (%) | 90–92 | <1 (Opaque) |

| Tensile Strength (MPa) | 52 | 26–33 |

| Chemical Resistance | Excellent (Acids, Bases, Alcohols) | Excellent (Acids, Bases, Organic Solvents) |

| Maximum Operating Temp (°C) | 60–70 | 82–90 |

| Flame Retardancy | Self-Extinguishing | Non Flame Retardant |

| Surface Hardness (Shore D) | 80 | 68–69 |

| Customizability | High: Printable, Thermoformable, Cuttable | Moderate: Cuttable, Not Thermoformable |

| Primary Applications | Glazing, Barriers, Displays, Printing Substrates | Food Prep, Industrial Surfaces, Anti-Corrosion Liners |

While HDPE cutting boards excel in high-abrasion, food-contact settings, PVC clear sheets offer unparalleled optical clarity, making them better suited for demanding transparency and display applications. Notably, the PVC material outperforms in flame resistance and surface hardness, expanding its usability in environments requiring strict safety measures.

Customization Options in High Transparency PVC Clear Sheet Production

The evolving demands of architects, designers, and manufacturers have led to significant advancements in the customization of high transparency PVC clear sheets. Modern extrusion and calendaring lines accommodate a wide range of sheet thicknesses (from ultra-thin 0.2 mm liners to robust 10 mm sheets), colors (including neutral clear, tints, and custom hues), and surface finishes (matte, gloss, anti-fog, and anti-scratch).

Custom embossing, UV-resistant coatings, and anti-glare treatments enhance performance in both exterior and interior settings. Sheets can be produced with food-grade, medical-grade, or fire-safe certifications according to global standards like FDA, REACH, and RoHS.

Technology-driven manufacturers also support precise digital cutting, CNC routing, and screen printing integration, enabling customer-driven geometries, graphics, and mounting solutions. Additionally, sustainable options — including recycled content and lead-free compounds — address emerging environmental standards, positioning the latest PVC clear sheets for future-ready manufacturing.

Application Case Studies across Various Industries

The range of use-cases for high transparency PVC clear sheet underscores its versatility. The following real-world applications illustrate its far-reaching utility:

- Healthcare & Medical Devices: Hospitals and diagnostic labs use high clarity PVC sheets as protective barriers, medical equipment windows, and sterilizable tray liners. In 2023, over 40% of medical testing labs adopted custom-molded PVC shields to reduce airborne contamination.

- Retail & Display: The retail sector employs these sheets for point-of-sale displays, shelving, price tag holders, and illuminated signage. Market research shows transparent PVC displays increase perceived product value and drive up to 17% higher product engagement rates.

- Food Processing: Custom-cut sheets function as machine guards, splash protectors, and conveyor belt covers, ensuring visibility and easy cleaning in food facilities.

- Security & Glazing: High transparency PVC clear sheets with enhanced thickness act as protective barriers in banks, schools, and government offices, offering shatter resistance and tamper-evident performance.

- Electronics Manufacturing: Static-dissipative PVC sheets are used in cleanroom enclosures and workstations for static and dust control.

The adaptability of these sheets enables designers to meet both functional and aesthetic objectives, aligning with the technical requirements of the industry while maintaining visual standards.

Key Considerations when Choosing PVC Materials

When selecting a high transparency PVC clear sheet or considering alternatives, a holistic approach is necessary. Key criteria include the required light transmittance, mechanical durability, chemical exposure, fire safety, and required certifications. For applications involving direct food contact or medical usage, opt for sheets compliant with FDA or EU standards, ensuring product safety.

Thickness tolerance and surface quality often impact downstream processing, such as printing or laser-cutting. For outdoor or sun-exposed situations, UV-stabilized sheets provide superior longevity and clarity retention. Environmental, health, and recycling considerations are also growing in importance; thus, suppliers offering verified low-emission and recyclable PVC compounds are now preferred by procurement teams in developed markets.

Finally, factors such as lead time, supplier reputation, and support for tailored geometries or branding will shape the success of a project using transparent PVC materials.

Conclusion: The Future of High Transparency PVC Clear Sheet

In today's competitive manufacturing environment, high transparency PVC clear sheet continues to set the benchmark for optical performance, durability, and process adaptability. Its combination of clarity, flame retardancy, chemical resistance, and high customizability places it at the forefront of transparent material selection for professionals across industries.

As sustainability and regulatory requirements evolve, the pathway for future product development lies in integrating recycled materials, advanced performance coatings, and improved environmental profiles. Manufacturers who invest in technological innovation and maintain strict quality control will be best positioned to meet the demands of a rapidly expanding and diversifying market. By choosing proven materials like super transparency PVC clear sheet and aligning with best-in-class suppliers, businesses can confidently address current needs and anticipate tomorrow’s challenges.

(high transparency pvc clear sheet)

FAQS on high transparency pvc clear sheet

Q: What are the main applications of high transparency PVC clear sheet?

A: High transparency PVC clear sheets are commonly used for packaging, protective covers, and display panels. Their clarity enhances visibility and presentation. They're also popular in craft and industrial projects.

Q: Does a super transparency PVC clear sheet offer better clarity compared to standard PVC sheets?

A: Yes, super transparency PVC clear sheets are engineered to have higher clarity and gloss. This makes them ideal for projects requiring excellent visual appeal. They minimize distortion and provide a glass-like appearance.

Q: Can I use high density polyethylene cutting boards for food preparation?

A: Absolutely, high density polyethylene (HDPE) cutting boards are food-safe and durable. They resist knife marks and are easy to clean. Their non-porous nature helps prevent bacterial growth.

Q: How thick are high transparency PVC clear sheets typically available?

A: High transparency PVC clear sheets usually range from 0.2mm to 5mm in thickness. Custom thicknesses can often be ordered from manufacturers. The choice depends on your application needs.

Q: Is high transparency PVC clear sheet resistant to UV and aging?

A: Some high transparency PVC clear sheets are UV-stabilized for outdoor use. These versions resist yellowing and embrittlement over time. Always check specifications for UV resistance before purchasing.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

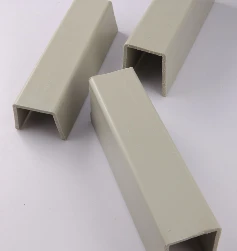

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025