Oct . 01, 2025 14:10 Back to list

PVC-M Water Supply Pipe: Tough, Corrosion-Resistant, Safe?

Inside the rise of PVC-M water mains: toughness without the trade‑offs

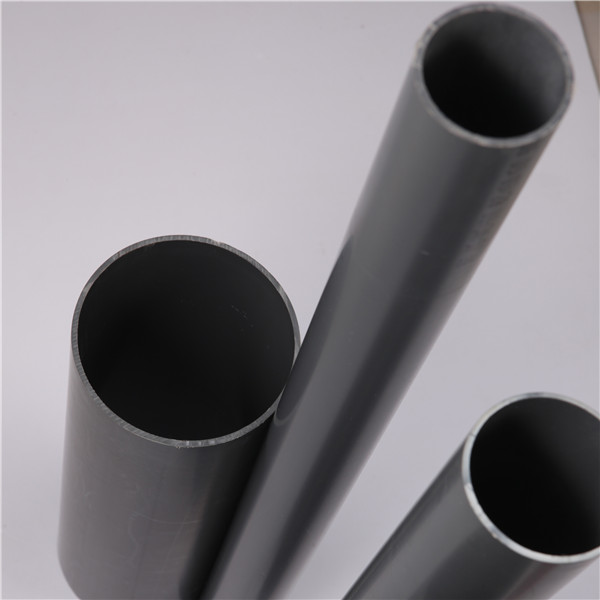

If you follow water infrastructure even casually, you’ve probably noticed the shift toward modified PVC. The first time I handled a PVC-M water supply pipe, I tapped it and thought, this feels different—leaner wall, yet oddly confident. That’s the point: high impact resistance, fewer breaks, and decent pressure ratings without ballooning costs.

What sets PVC-M water supply pipe apart

PVC-M uses rigid inorganic particles to toughen the matrix. In practice, you keep the high tensile strength of PVC while gaining crack resistance and impact energy absorption. Many customers say it feels “forgiving” during installation—less breakage on cold mornings, fewer trenchside headaches.

Quick specs (real-world use may vary)

| Standard | CJ/T272—2008; reference practices: ISO 1452 (PVC pressure systems) |

| Size range | ≈ Φ20 mm — Φ800 mm |

| Pressure classes | PN10 / PN12.5 / PN16 (typical) |

| Joints | Rubber ring (bell-and-spigot) for mains; solvent cement on small diameters (where allowed) |

| Temperature | 0–45°C recommended for pressure service |

| Service life | Design target ≈ 50 years at 20°C (per long-term hydrostatic strength methods) |

| Colors | Blue, gray; custom stripe/printing available |

How it’s made (the short version)

- Materials: PVC resin (K≈65–67), inorganic toughening agents, stabilizers, pigments.

- Compounding: high‑intensity mixing; controlled particle dispersion (the secret sauce).

- Extrusion: twin‑screw → vacuum calibration → multi‑stage cooling → inline printing.

- Joints: belling with gasket groove; dimensional checks per CJ/T272—2008.

- Testing: ISO 1167 hydrostatic tests (1 h, 48 h, 165 h); impact tests; drop weight; ring stiffness.

Application snapshots

- Municipal distribution and service connections.

- Building cold water risers (where codes permit).

- Irrigation trunk and laterals; agriculture likes the low friction.

- Industrial process water and fishery lines (non‑potable or potable per local certification).

Field data and testing (example)

For a DN160 PN12.5 line segment, hydrostatic test at 20°C, 1 h at ≈18.7 bar (≈1.5×PN) passed without blistering or craze lines; 165 h test met ISO 1167 creep criteria. To be honest, that’s what you’d expect from a well‑compounded PVC-M water supply pipe.

Vendor comparison at a glance

| Vendor | Size Range | Lead Time | Customization | Notes |

|---|---|---|---|---|

| Lida Plastic (Hebei, China) | Φ20–Φ800 mm | ≈ 10–20 days | Color, print, PN, gasket brand | Strong on large‑diameter mains |

| Importer A | Φ20–Φ400 mm | ≈ 4–6 weeks | Limited colors | Stock‑based availability |

| Local Distributor B | Φ20–Φ315 mm | 1–2 weeks (in‑stock) | Print only | Fast for small jobs |

Customization and support

- PN classes PN10–PN16; SDR options on request.

- Elastomer gaskets (EPDM/NBR) per potable or industrial needs.

- Project prints, meter marks, coil/straight lengths (where feasible).

- Certificates available upon request: ISO 9001, potable approvals (e.g., NSF/ANSI/CAN 61 or WRAS) depending on market.

Case notes from the field

In a northern county retrofit (cold winters, clay soil), contractors swapped legacy AC mains for PVC-M water supply pipe PN12.5. Reported outcomes after one season: fewer impact‑related breaks during backfill, smoother chlorination, and around 8–10% lower pump energy thanks to clean internal surfaces. Not a lab trial—just what crews told me on site.

Why spec it

- High impact and anti‑crack behavior; better in trench mishaps.

- Lightweight, easy handling; lower install costs.

- Corrosion‑free; low roughness keeps C‑factor high over time.

- Stable pricing versus metals, which—let’s be honest—swing wildly.

Origin and manufacturing: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250.

Citations

- CJ/T 272—2008: Modified PVC (PVC‑M) pipes for water supply.

- ISO 1452: Plastics piping systems for water supply and for buried and above-ground drainage and sewerage — PVC‑U.

- ISO 1167: Thermoplastics pipes — Determination of resistance to internal pressure.

- ISO 9080: Determination of long‑term hydrostatic strength of thermoplastics pipe materials.

- NSF/ANSI/CAN 61: Drinking Water System Components — Health Effects.

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025