Nov . 02, 2025 04:20 Back to list

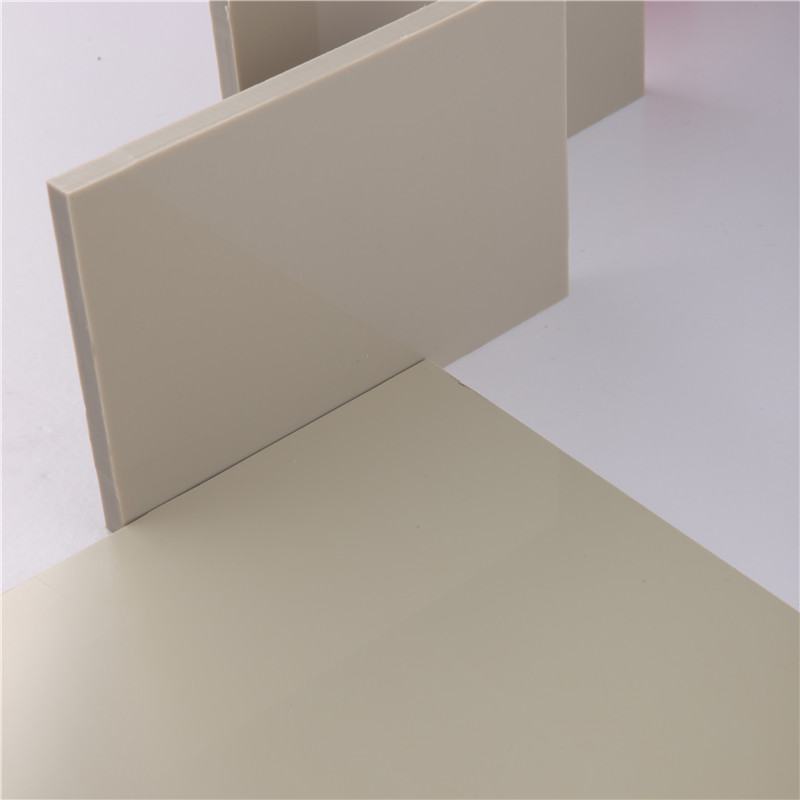

PPH Sheet | Chemical-Resistant & Weldable for Tanks

PPH Sheet is a key solution in the chemical industry industry, specifically within Plastic and plastic products and Manufacturing of plastic plates, sheets, and pipes. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PPH Sheet Overview

- Benefits & Use Cases of PPH Sheet in Manufacturing of plastic plates, sheets, and pipes

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on PPH Sheet from Baoding Lida Plastic Industry Co., Ltd

PPH Sheet Overview

PPH sheet—polypropylene homopolymer sheet—is a robust engineering plastic selected across the chemical industry for its outstanding chemical resistance, stiffness, low density, and excellent weldability. In the Plastic and plastic products segment, and especially within the Manufacturing of plastic plates, sheets, and pipes, PPH sheet is a go-to substrate for fabricating chemical tanks, fume scrubbers, pickling lines, ventilation ducts, and liners exposed to acids, alkalis, and salts. Its low moisture absorption and high purity make it equally suitable for ultrapure water systems and process equipment where contamination must be minimized.

From a technical perspective, PP-H typically offers high rigidity, good heat resistance for many service environments, and a broad processing window: it can be CNC-machined, thermoformed, and hot-air or extrusion welded to tight tolerances. Many buyers specify PPH for its smooth surface, low stress-cracking tendency, and compatibility with standard plastic fabrication techniques, enabling leak-tight tanks and long-lived pipe systems. Baoding Lida Plastic Industry Co., Ltd manufactures consistently flat, dimensionally stable PPH sheets with tight thickness control and application-driven options (e.g., colors, surface finishes, and weld-matched rods), supporting OEMs and fabricators who must deliver repeatable, compliant equipment at scale.

Benefits & Use Cases of PPH Sheet in Manufacturing of plastic plates, sheets, and pipes

PPH sheet excels wherever corrosion resistance and clean fabrication are essential. Typical applications include plating and etching tanks, acid/alkali storage, vent gas scrubbers, pickling lines, and scrubber internals. In the context of manufacturing plates, sheets, and pipes, PPH serves as a versatile base material that can be cut, folded, welded, and bonded into complex geometries—yielding lightweight assemblies that replace traditional metals and FRP in demanding chemical service. Its smooth surface facilitates high-quality weld beads and sanitary designs, while its stiffness helps maintain dimensional integrity in large panels and ductwork.

Competitive advantages include long-term resistance to many acids and bases, low density for easier handling and installation, and excellent weldability that reduces leak risk and rework. When paired with matched welding rod, fabricators can achieve uniform mechanical performance across seams. Baoding Lida Plastic Industry Co., Ltd leverages deep expertise in PPH compounding and extrusion to provide consistent melt-flow characteristics and flatness—key to minimizing stress and ensuring high-quality tanks, flanges, and pipe fittings. For B2B decision makers, this translates into faster throughput on the shop floor and fewer warranty claims in the field.

Cost, Maintenance & User Experience

Total cost of ownership is where PPH sheet delivers measurable value. Compared with metals in corrosive environments, PPH does not require painting, cathodic protection, or frequent relining—cutting long-term maintenance spend and downtime. Its light weight reduces transport and installation costs, while easy machinability and weldability lower fabrication hours. For many facilities, the ROI emerges through fewer unplanned stoppages, simplified inspection routines, and extended equipment life in harsh chemical service. In short, PPH sheet often pays back quickly when lifecycle costs are considered, not just initial material price.

Feedback from users in the Plastic and plastic products sector highlights stable quality, dependable weld performance, and predictable behavior during thermoforming and CNC machining. Fabricators report clean edges, consistent bead appearance, and excellent dimensional stability—key factors for leak-tight tanks and long duct runs. Baoding Lida Plastic Industry Co., Ltd supports customers with application guidance and material options tailored to operating environments, helping engineering teams standardize on PPH sheet grades that balance stiffness, chemical resistance, and processability for reliable outcomes at scale.

Sustainability & Market Trends in chemical industry

Sustainability imperatives and tightening regulations are reshaping material choices in chemical processing and equipment fabrication. PPH sheet aligns with these trends as a recyclable, lightweight polymer that helps reduce system mass and, by extension, transport energy. Its corrosion resistance minimizes the need for coatings and solvents associated with maintenance, supporting cleaner operations. As companies move to lower-emission processes and circular models, demand is growing for durable plastics with long service lives and end-of-life recovery pathways—areas where PPH technology is well-positioned.

Baoding Lida Plastic Industry Co., Ltd takes a forward-looking approach by emphasizing material consistency, waste reduction in extrusion, and offerings that enable customers to fabricate efficient, long-lived equipment. By focusing on quality, processability, and recyclability, the company helps OEMs and plant operators meet internal ESG goals while maintaining performance and safety. As market needs evolve—from stricter emissions abatement systems to ultrapure fluid handling—Lida’s PPH sheet options provide a reliable foundation for next-generation equipment that balances durability, compliance, and cost.

Conclusion on PPH Sheet from Baoding Lida Plastic Industry Co., Ltd

For B2B decision makers in the chemical industry—particularly across Plastic and plastic products and the Manufacturing of plastic plates, sheets, and pipes—PPH sheet delivers a compelling blend of chemical resistance, stiffness, weldability, and lifecycle value. Baoding Lida Plastic Industry Co., Ltd is a trusted partner for consistent, fabrication-ready sheets that help reduce maintenance and accelerate project timelines. Ready to specify or request a quote? Contact us: email: lidaplastic@ldsy.cn. Visit our website: https://www.lidaplastic.com.

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025

-

Durable and Efficient HDPE Sprinkler Pipe Fittings for Global Water Systems

NewsNov.18,2025

-

HDPE Sprinkler Pipe – Durable, Efficient Irrigation Solutions for Global Use

NewsNov.18,2025

-

Comprehensive Guide to PVC Pipe Coupling: Durable, Cost-Effective Piping Connections

NewsNov.17,2025