Там . 22, 2025 09:27 Тізімге оралу

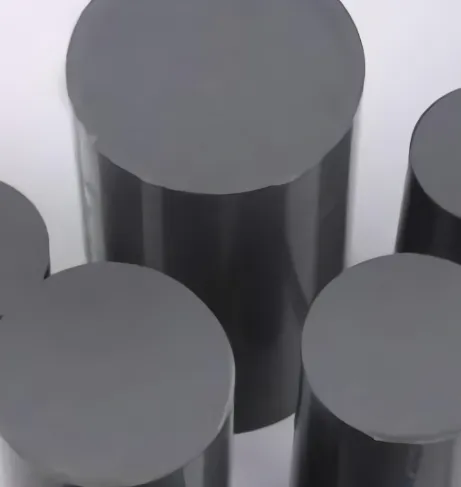

PVC Rod Solutions for Industrial Excellence

In the field of industrial plastic materials, the selection of the right rod product can have a significant impact on both operational efficiency and long-term cost control. Among the many engineered plastics available, ПВХ дисплейі, including ПВХ дөңгелек таяқшасы, PVC grey rod, and ПВХ шаршы таяқшасы, continues to gain market attention for its comprehensive performance advantages and adaptability across various sectors. Whether the need is for high chemical resistance, dimensional stability, or ease of fabrication, these rods have proven indispensable in engineering, chemical processing, and construction applications.

Versatile Applications of PVC Rod in Modern Industry

The usage scenarios for ПВХ дисплейі products are extensive and constantly evolving. Industries requiring high durability and resilience to corrosive substances have especially embraced PVC grey rod as a preferred material due to its excellent chemical resistance and mechanical strength. From the construction of chemical tanks and acid-resistant pipelines to custom industrial components, ПВХ дисплейі proves itself as a dependable solution.

One reason for its popularity is that ПВХ дөңгелек таяқшасы offers uniformity in both shape and density, making it easy to machine and fabricate into complex parts. This characteristic makes it particularly suitable for precision applications, such as valve bodies, spacers, fixtures, and insulating components in electrical systems. The consistent performance of these rods under a wide range of temperatures and pressures further boosts their relevance in mechanical engineering and fluid handling systems.

Durability and Processing Benefits of PVC Grey Rod

Among the family of ПВХ дисплейі products, PVC grey rod stands out due to its superior balance between physical strength and lightweight properties. It is this balance that makes it ideal for applications that require rigidity without adding unnecessary weight. In manufacturing environments where machinery operates under harsh conditions, the use of PVC grey rod allows engineers to maintain structural integrity without compromising flexibility.

Beyond strength, its processability is another major advantage. These rods can be easily welded, glued, and cut to exact specifications, which streamlines manufacturing operations and minimizes material waste. Moreover, the surface hardness of PVC grey rod contributes to its long-lasting wear resistance, reducing maintenance intervals and costs for industrial machinery. It resists cracking even when exposed to heavy mechanical stresses or fluctuating thermal environments, making it a suitable alternative to metals in many medium-duty applications.

PVC Square Rod for Specialized and Structural Uses

When structural geometry is a key requirement, ПВХ шаршы таяқшасы offers a unique advantage. Unlike its round counterpart, the square shape delivers better alignment and increased contact surface for joining and assembly processes. This makes it particularly useful in applications such as chemical drainage systems, structural panels, and environmental protection components.

The flame-retardant nature of ПВХ шаршы таяқшасы enhances its suitability in sectors that demand high safety standards, including environmental engineering, sulfuric acid production, and pharmaceutical manufacturing. Its ability to maintain dimensional stability under heat and chemical exposure sets it apart from other polymer-based alternatives. Furthermore, its dense, non-crystalline molecular structure minimizes the risk of internal stress cracks, which is critical in high-pressure and long-term installation settings.

The visual aspect of ПВХ шаршы таяқшасы also plays a role in design-conscious projects. Its clean, angular lines and customizable lengths allow for aesthetic and functional integration into architectural or display-oriented applications, such as lab countertops or industrial workstations. This combination of form and function positions ПВХ шаршы таяқшасы as an increasingly popular material in modern engineering design.

Choosing the Right PVC Rod for Your Needs

The decision to select between ПВХ дөңгелек таяқшасы, PVC grey rod, or ПВХ шаршы таяқшасы depends on the specific requirements of your project. For rotational components or installations involving circular motion, ПВХ дөңгелек таяқшасы offers the ideal balance of strength and flexibility. Its cylindrical geometry ensures even load distribution and smooth operation under stress.

If your application demands resistance to corrosive agents such as acids or alkalis, PVC grey rod provides the chemical shielding and physical strength needed for safe and efficient performance. Its subtle color also makes it an excellent choice for applications where visual wear monitoring is required.

Meanwhile, ПВХ шаршы таяқшасы is the go-to option for structural or modular assemblies that require a consistent profile and robust load-bearing capacity. Its flat surfaces enable precise alignment in machine parts or framework designs, making it a valuable material in heavy-duty industrial systems.

Whichever variant is selected, all ПВХ дисплейі products are renowned for their electrical insulation properties, making them equally effective in electrical panel boards, cable guides, and transformer installations. Their low moisture absorption rates and resistance to biological degradation also mean that these materials maintain their form and functionality in outdoor or humid environments, contributing to long-term reliability.

PVC Rod FAQs

What is a ПВХ дисплейі and what are its primary industrial uses?

A ПВХ дисплейі is a solid, cylindrical or prismatic bar made from polyvinyl chloride, a synthetic plastic polymer. It is commonly used in mechanical, electrical, and chemical processing industries due to its strength, durability, and resistance to a wide range of chemicals. Depending on its shape—whether ПВХ дөңгелек таяқшасы, PVC grey rod, or ПВХ шаршы таяқшасы—it serves various purposes such as in valve components, chemical tanks, structural supports, or insulating spacers.

What makes PVC grey rod different from standard ПВХ дисплейі?

PVC grey rod typically has enhanced chemical resistance and flame retardant properties compared to standard clear or white PVC. Its coloration signifies industrial-grade quality and is preferred in applications where prolonged exposure to corrosive substances is expected. Its enhanced rigidity and thermal stability make it suitable for high-performance environments like sulfuric acid production and environmental management systems.

When should I use a ПВХ шаршы таяқшасы instead of a ПВХ дөңгелек таяқшасы?

A ПВХ шаршы таяқшасы is more suitable when precise edge alignment, greater surface contact, or rectangular profiles are needed. These rods are often used in assembly lines, construction modules, and structural applications that benefit from a stable flat edge. In contrast, ПВХ дөңгелек таяқшасы is ideal for parts that will undergo rotation, turning, or need fluid motion integration.

Can ПВХ дисплейі materials withstand exposure to acids and bases?

Yes, one of the main advantages of ПВХ дисплейі materials is their strong resistance to a wide variety of corrosive chemicals, including acids, bases, and salts. This makes them suitable for chemical processing applications, including those in plating facilities, laboratories, and wastewater treatment plants. However, it is important to verify compatibility with specific chemicals and concentrations before selection.

What are the machining and fabrication capabilities of ПВХ дисплейі products?

ПВХ дисплейі materials are extremely easy to machine using standard metal or wood tools. They can be cut, drilled, milled, turned, and bonded with great precision, which makes them ideal for custom part fabrication. Their thermoplastic nature also allows them to be thermoformed and welded into complex assemblies. Additionally, their low internal stress levels reduce the risk of warping or cracking during processing, further simplifying manufacturing workflows.

-

Welding Rod Solutions for Durable Plastic Fabrication

ЖаңалықтарAug.22,2025

-

Reliable Solutions for Modern Infrastructure: Hdpe Pipe Excellence

ЖаңалықтарAug.22,2025

-

PVC Rod Solutions for Industrial Excellence

ЖаңалықтарAug.22,2025

-

Innovative PVC Sheet Solutions for Industrial Performance

ЖаңалықтарAug.22,2025

-

High-Performance PP Sheet Solutions for Modern Industries

ЖаңалықтарAug.22,2025

-

High-Performance Plastic Solutions

ЖаңалықтарAug.22,2025