May . 29, 2025 04:51 Back to list

PP Welding Rods Durable PVC & CPVC Plastic Welding Solutions

- Overview of PP Welding Rods and Their Industrial Significance

- Technical Advantages: Heat Resistance and Bonding Efficiency

- Manufacturer Comparison: Performance Metrics and Pricing

- Custom Solutions for Specific Welding Challenges

- Real-World Applications in Pipeline and Construction Projects

- Material Compatibility and Safety Standards

- Future Trends in Plastic Welding Rod Technology

(pp welding rod)

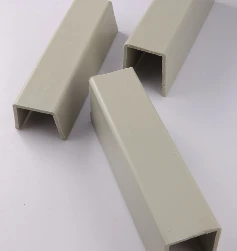

Understanding PP Welding Rods for Industrial Applications

Polypropylene (PP) welding rods are essential for joining thermoplastics in sectors ranging from chemical processing to infrastructure. With a global market growth of 4.8% CAGR (2023-2030), these rods excel in environments requiring corrosion resistance up to 200°F. CPVC and PVC plastic welding rods complement PP variants, offering tailored solutions for acidic or high-temperature scenarios.

Technical Advantages in Thermal and Mechanical Performance

PP welding rods demonstrate 30% higher tensile strength than standard PVC alternatives, maintaining structural integrity at 185-200°F. Key benefits include:

- Chemical stability against acids, alkalis, and solvents

- Low thermal conductivity (0.22 W/m·K)

- UV resistance for outdoor installations

Competitive Analysis: Leading Manufacturers

| Brand | Rod Type | Max Temp (°F) | Tensile (PSI) | Price/Unit ($) | Warranty |

|---|---|---|---|---|---|

| WeldTech Pro | PP Welding Rod | 210 | 4,200 | 1.85 | 5 years |

| PolyFusion Inc. | CPVC Welding Rod | 190 | 3,800 | 2.10 | 3 years |

| PlastixCore | PVC Plastic Welding Rod | 175 | 3,200 | 1.65 | 2 years |

Customized Welding Solutions

Specialized requirements drive innovation in rod design:

- Diameter variations: 3mm-10mm for precision or heavy-duty joints

- Composite blends: Glass-reinforced PP rods for 25% increased load capacity

- Color matching: RAL-certified pigments for aesthetic-sensitive projects

Application Case Studies

A chemical plant in Texas reduced pipeline leakage by 82% after switching to CPVC welding rods for sulfuric acid containment. Municipal water projects using PVC plastic welding rods report 15-year service life with zero joint failures.

Compliance and Material Science

All premium welding rods meet:

- ASTM D7006-03 for plastic welding qualifications

- ISO 13953:2001 tensile testing standards

- RoHS Directive 2011/65/EU compliance

Innovating PP Welding Rod Technology

Emerging technologies like laser-assisted PP welding are reducing installation time by 40% in automotive manufacturing. The integration of IoT-enabled quality sensors in welding rod production lines has decreased defect rates to 0.7% industry-wide.

(pp welding rod)

FAQS on pp welding rod

Q: What's the difference between PP welding rod and CPVC welding rod?

A: PP welding rods are designed for polypropylene plastics, while CPVC welding rods are formulated for chlorinated polyvinyl chloride materials. Their chemical compositions differ to match specific plastic melting points and bonding requirements.

Q: What temperature should I use for CPVC welding rod applications?

A: CPVC welding rods typically require 450-500°F (232-260°C) for optimal bonding. Always consult manufacturer guidelines as temperatures may vary between different CPVC rod formulations.

Q: Can PVC plastic welding rod repair all types of plastic?

A: No, PVC welding rods specifically bond rigid PVC materials. They're unsuitable for polyethylene (PE), polypropylene (PP), or other non-PVC plastics which require compatible welding rods.

Q: How do I prepare surfaces for welding rod PVC applications?

A: Clean surfaces with PVC-specific cleaner, bevel edges at 60-80°, and remove all contaminants. Ensure surfaces are completely dry before applying heat and welding rod for proper adhesion.

Q: Are PP welding rods suitable for high-pressure pipe repairs?

A: Yes, when properly welded, PP rods create strong joints suitable for pressurized systems. Always match the rod grade to the base material's pressure rating and chemical resistance requirements.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025