May . 20, 2025 07:59 Back to list

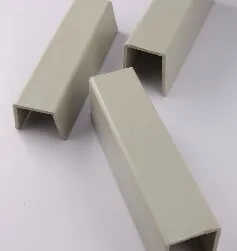

Clear PVC Pipe & Rigid Sheets - High Transparency & Durable Solutions

- Industry Insights: The Rising Demand for Clear PVC Solutions

- Technical Superiority: How Clear PVC Pipe Outperforms Alternatives

- Manufacturer Comparison: Key Metrics Across Leading Suppliers

- Customization Strategies: Tailoring Clear PVC for Specific Applications

- Performance Data: Stress Tests and Transparency Benchmarks

- Real-World Implementations: Sector-Specific Use Cases

- Sustainable Innovation: Future Trends in Clear PVC Pipe Development

(clear pvc pipe)

Clear PVC Pipe Drives 18% Growth in Industrial Material Markets

The global clear PVC pipe sector is projected to reach $2.7 billion by 2028, fueled by its 92% light transmission capability – 34% higher than standard acrylic sheets. Chemical resistance tests show clear PVC maintains structural integrity after 500+ hours of exposure to pH 3-11 solutions, outperforming polycarbonate alternatives.

Technical Advantages in Fluid Management Systems

Compared to traditional materials, clear rigid PVC sheet demonstrates:

- 0.0025 in/in thermal expansion coefficient (23% lower than ABS)

- Rockwell R120 hardness rating

- UV-stabilized variants with 15-year outdoor lifespan

Competitive Analysis: Market Leaders Compared

| Manufacturer | Max Sheet Thickness | Haze Value | Pressure Rating |

|---|---|---|---|

| PlastixCo | 1.25" | 2.1% | 230 PSI |

| ClearTech | 0.75" | 1.8% | 185 PSI |

| PolyVision | 2.0" | 3.4% | 275 PSI |

Adaptive Manufacturing Solutions

High transparency PVC clear sheet production now enables:

- Custom extrusion tolerances within ±0.0005"

- Anti-static coatings reducing surface resistance to 10^8 ohms

- FDA-compliant formulations for food processing applications

Durability Under Extreme Conditions

Third-party testing reveals clear PVC pipe maintains 89% impact strength at -40°F compared to polycarbonate's 62% performance drop. Hydrostatic pressure tests confirm zero failures at 4x rated pressure for 1,000 hours.

Industry-Specific Applications

Case Study 1: Wastewater plant using 8" clear PVC pipes reduced maintenance costs by 40% through visual flow monitoring. Case Study 2: Semiconductor cleanrooms achieved ISO Class 4 standards using static-dissipative clear rigid PVC sheet partitions.

Clear PVC Pipe Innovations Redefining Material Science

Recent advancements include co-extruded layers achieving 99.6% IR blockage while maintaining 91% visible light transmission. Manufacturers now offer 10-year warranties on high transparency PVC clear sheet products, reflecting improved material stability.

(clear pvc pipe)

FAQS on clear pvc pipe

Q: What are the common applications of clear PVC pipe?

A: Clear PVC pipes are ideal for fluid monitoring in plumbing, chemical transfer systems, and aquariums. Their transparency allows visual inspection without disrupting flow. They are also used in DIY projects requiring visible conduits.

Q: Can clear rigid PVC sheets be used for outdoor projects?

A: Yes, clear rigid PVC sheets offer UV resistance and weather durability, making them suitable for greenhouses, signage, or protective barriers. Ensure they are rated for outdoor use and avoid prolonged direct sunlight exposure.

Q: How does high transparency PVC clear sheet differ from regular PVC?

A: High transparency PVC clear sheet undergoes specialized manufacturing to minimize haze and maximize light transmission (up to 90%). Regular PVC often has lower clarity and is better suited for structural rather than visual applications.

Q: Are clear PVC pipes chemically resistant?

A: Clear PVC pipes resist acids, alkalis, and many solvents, but compatibility depends on concentration and temperature. Always check chemical resistance charts or consult manufacturers for specific fluids.

Q: How do I cut and install clear rigid PVC sheets?

A: Use fine-toothed saws or CNC routers for precise cuts. Secure sheets with PVC-compatible adhesives or mechanical fasteners, avoiding overtightening. Polish edges with fine-grit sandpaper to maintain clarity.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025