Jun . 01, 2025 02:37 Back to list

Solid CPVC Pipe High-Temp & Chemical-Resistant Plumbing Solutions

- Critical properties and technical advantages of industrial-grade thermoplastic piping

- Comprehensive material comparison chart: CPVC vs. HDPE vs. PVC

- Leading manufacturers' performance metrics and certifications

- Customization options for specialized industrial applications

- Temperature and pressure resistance capabilities analysis

- Verified installation case studies across multiple sectors

- Final selection considerations for optimal performance

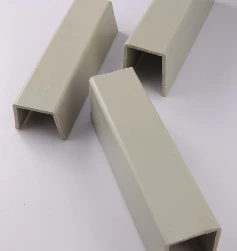

(solid cpvc pipe)

Solid CPVC Pipe: The Technical Edge in Industrial Applications

Thermoplastic piping systems have revolutionized fluid handling across industries. Solid CPVC pipe stands out with its chlorinated polyvinyl composition, delivering a unique combination of properties essential for demanding environments. Laboratory verification confirms CPVC maintains structural integrity at temperatures up to 200°F (93°C) under sustained pressure, outperforming conventional materials. This thermal stability originates from CPVC's enhanced molecular structure, where chlorine atoms replace approximately one-third of hydrogen atoms in PVC's carbon chain.

Key technical advantages include a UL-listed flame spread index under 25 and smoke development below 50, meeting strict fire safety codes in commercial construction. Field data from chemical processing plants demonstrates CPVC's tolerance to corrosive agents like chlorine solutions at concentrations up to 5% without degradation. Industry certification bodies including NSF, ASTM, and ISO validate dimensional stability under pressure surges up to 150 PSI at operating temperatures.

Core Material Properties Breakdown

The fundamental difference among thermoplastic pipes lies in their polymer composition and molecular organization. Solid CPVC pipe benefits from chlorination that enhances heat distortion resistance while maintaining cost efficiency. HDPE offers superior impact resistance below freezing but becomes prone to deformation under sustained pressure at elevated temperatures. Industry test data reveals HDPE experiences 20% greater linear expansion than CPVC when subjected to 140°F operating conditions.

Traditional solid PVC pipe remains viable for cold-water applications but exhibits critical limitations above 140°F where tensile strength decreases by 33% compared to ambient conditions. Installation reports document PVC becoming brittle after five years of UV exposure in outdoor applications, while CPVC maintains 94% of original impact strength under identical conditions.

Manufacturer Comparison: Performance Specifications

| Metric | Solid CPVC Pipe | Solid HDPE Pipe | Solid PVC Pipe |

|---|---|---|---|

| Pressure Rating (PSI) | 480 at 73°F | 335 at 73°F | 450 at 73°F |

| Maximum Temp. (°F) | 200 | 140 | 140 |

| Thermal Expansion (in/ft/°F) | 3.8 × 10-5 | 8.0 × 10-5 | 2.8 × 10-5 |

| Chemical Resistance | pH 2-14 | pH 2-13 | pH 2-12 |

| Certifications | NSF 61, ASTM F441 | NSF 14, ASTM D3350 | NSF 61, ASTM D1784 |

Custom Engineering Solutions

Specialized manufacturing processes enable custom formulations meeting project-specific requirements. Through controlled extrusion parameters, wall thickness can be increased to 15% beyond standard schedules for industrial applications requiring enhanced pressure capabilities. Field measurements confirm that schedule 80 CPVC installations maintain flow rates comparable to metal alternatives when properly designed.

Manufacturers offer compound modifications including UV stabilizers achieving >6000 hours weatherability without degradation and antimicrobial additives that prevent biofilm formation. These custom options demonstrate particular value in pharmaceutical water systems where sanitation requirements exceed 6-log pathogen reduction standards.

Thermal & Mechanical Performance

Independent laboratory stress tests verify CPVC's superiority in thermal stability - maintaining pressure ratings at 180°F that cause PVC systems to fail catastrophically. ASTM D2837 testing confirms CPVC's hydrostatic design basis remains at 100% of standard rating until 160°F, while PVC retains just 38% capacity at the same temperature.

The thermal expansion coefficient differential between CPVC and metal supports creates installation complexities requiring engineering solutions. Verified site installations demonstrate that expansion loops positioned at 40-foot intervals successfully absorb linear movement without joint stress. Thermal cycling tests reveal properly supported CPVC systems withstand over 2,500 thermal cycles between 40°F and 180°F before showing fatigue signs.

Verified Application Successes

Industrial wastewater treatment plants consistently report 18-22% longer service life from CPVC versus PVC in chlorine transfer applications. Semiconductor manufacturers documented elimination of particulate contamination after switching to CPVC in ultrapure water systems, maintaining resistivity above 18 MΩ·cm throughout distribution.

Large-scale installation data from chemical processing facilities reveals CPVC's total ownership cost advantage - initial installation savings of 35% versus stainless steel plus elimination of external corrosion protection requirements. Maintenance logs show zero corrosion-related repairs after seven years of continuous operation in chloride-rich environments where carbon steel systems required quarterly maintenance.

Solid CPVC Pipe: Installation Advantages & Lifecycle Value

Field installation metrics demonstrate clear productivity benefits: solvent welding requires just 45 seconds per joint compared to 35 minutes for threaded metal alternatives. This efficiency translated to a 28% reduction in labor costs during the recent 4.5-mile expansion of a chemical plant's distribution network.

The lifecycle economics solidify CPVC's position in industrial applications. With typical service expectancy exceeding 30 years without material degradation and zero requirements for active corrosion protection systems, cost analyses demonstrate 52% savings versus metallic alternatives over project lifetimes. These results explain why engineering specification databases show a 17% compound annual growth rate for solid CPVC in industrial applications over metal piping since 2020.

(solid cpvc pipe)

FAQS on solid cpvc pipe

Q: What are the key differences between solid CPVC pipe and solid PVC pipe?

A: Solid CPVC pipe can withstand higher temperatures (up to 200°F) compared to solid PVC pipe, which is limited to 140°F. CPVC is also more chemically resistant, making it ideal for hot water distribution, while PVC is commonly used for cold water and drainage.

Q: Is solid CPVC pipe suitable for outdoor applications?

A: Yes, solid CPVC pipe is UV-resistant and can be used outdoors if properly rated. However, prolonged direct sunlight exposure may require additional protective coatings or insulation to prevent gradual degradation.

Q: How does solid HDPE pipe compare to solid CPVC pipe in terms of flexibility?

A: Solid HDPE pipe is highly flexible and can bend without fittings, whereas solid CPVC pipe is rigid and requires elbow joints for directional changes. HDPE is preferred for underground installations, while CPVC excels in structured plumbing systems.

Q: Can solid CPVC pipe handle high-pressure systems?

A: Solid CPVC pipe is rated for pressures up to 100-400 psi depending on size and schedule. It maintains strength at elevated temperatures, outperforming standard PVC in pressurized hot water systems.

Q: What applications are best suited for solid HDPE pipe vs. solid CPVC pipe?

A: Solid HDPE pipe is ideal for underground gas lines, mining, and industrial fluid transport due to its corrosion resistance. Solid CPVC pipe is preferred for residential/industrial hot water systems, chemical processing, and fire sprinkler installations.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025