Aug . 11, 2025 12:00 Back to list

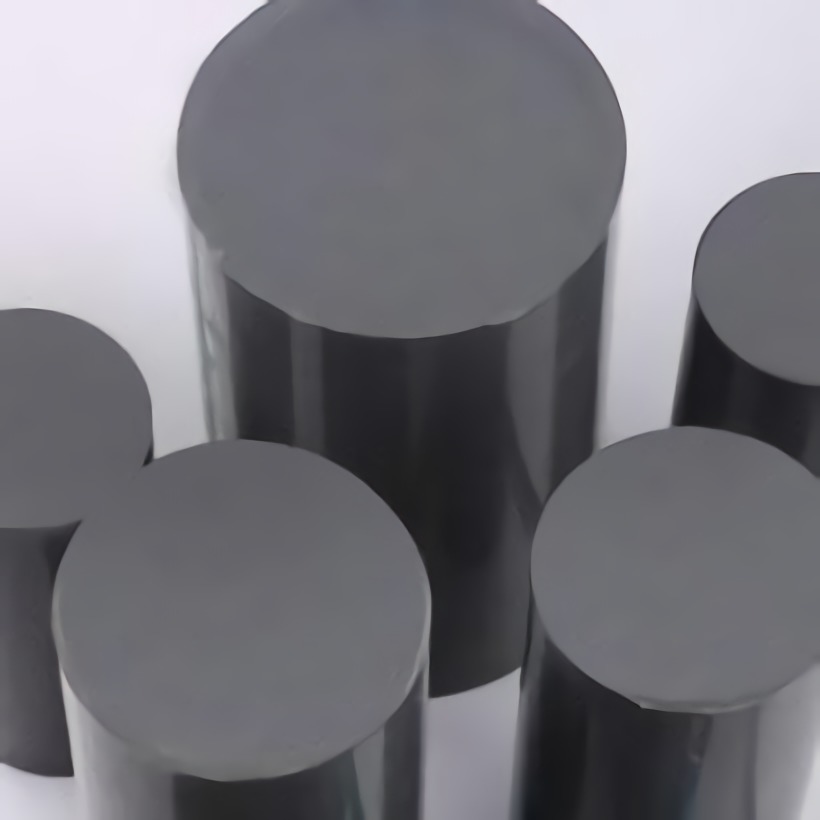

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

Understanding the Versatility of PVC Round Rods in Modern Industrial Applications

In the realm of advanced engineering plastics, the PVC round rod stands out as a fundamental component, widely recognized for its robust properties and diverse applicability across numerous sectors. The demand for materials that offer an optimal balance of chemical resistance, mechanical strength, and cost-efficiency continues to grow, positioning PVC round rod as a preferred choice for B2B decision-makers and technical personnel. This material's increasing adoption is a testament to its reliability and adaptability in critical infrastructure, manufacturing, and processing environments. It represents a mature technology continually refined to meet stringent industry specifications and operational demands, supporting innovation in fields from water treatment to heavy industry.

Current industry trends highlight a significant shift towards sustainable and durable materials capable of withstanding harsh operational conditions without compromising performance or longevity. PVC round rod perfectly aligns with this trend, offering exceptional resistance to a wide range of corrosive agents, making it indispensable in applications where traditional metals would quickly degrade. Furthermore, its inherent insulating properties and ease of fabrication contribute to its versatility, driving its prominence in electrical components, fluid handling systems, and structural supports. This comprehensive guide delves into the technical aspects, manufacturing excellence, and strategic advantages that make PVC round rod a cornerstone in modern industrial design and execution.

The Advanced Manufacturing Process of PVC Round Rods

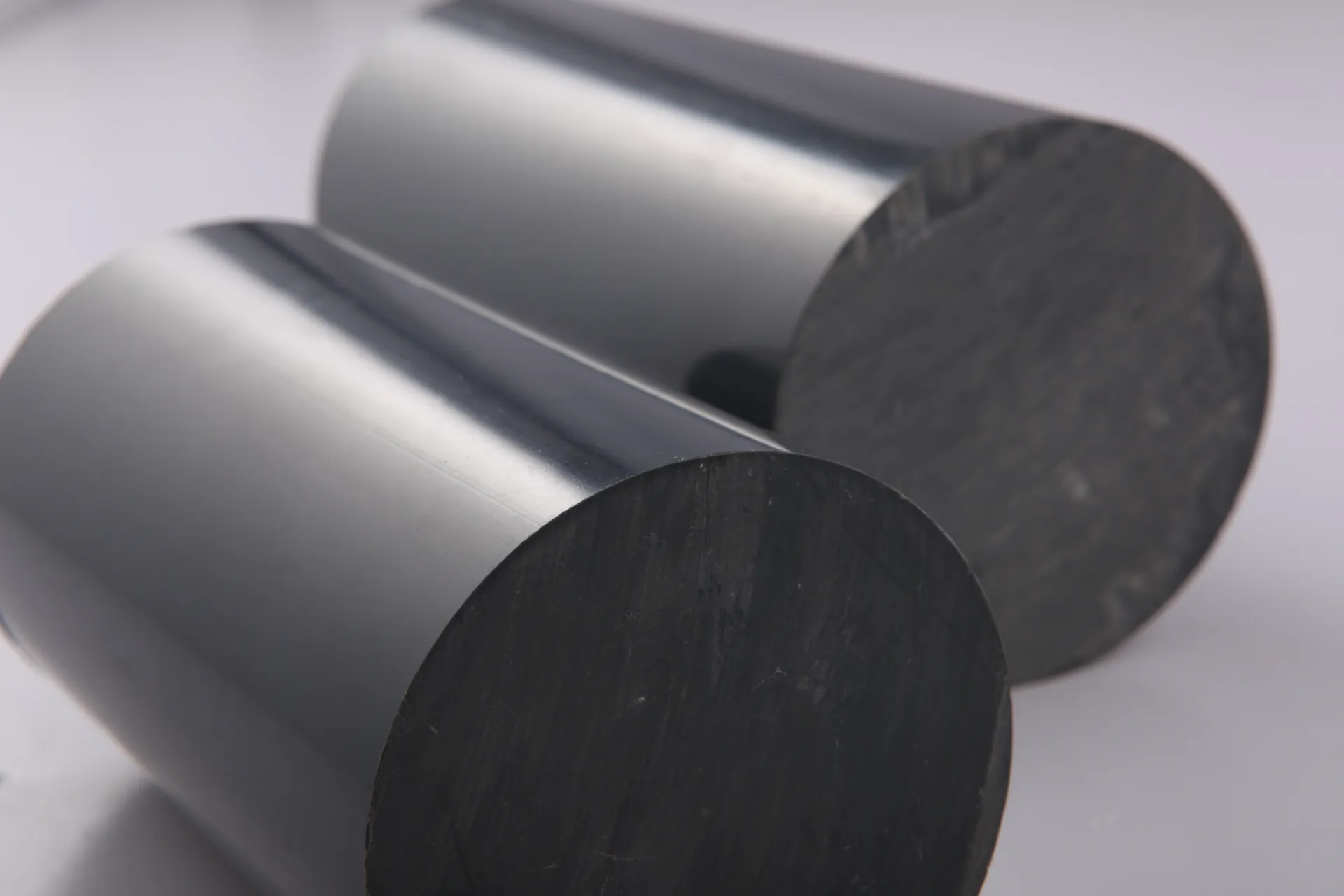

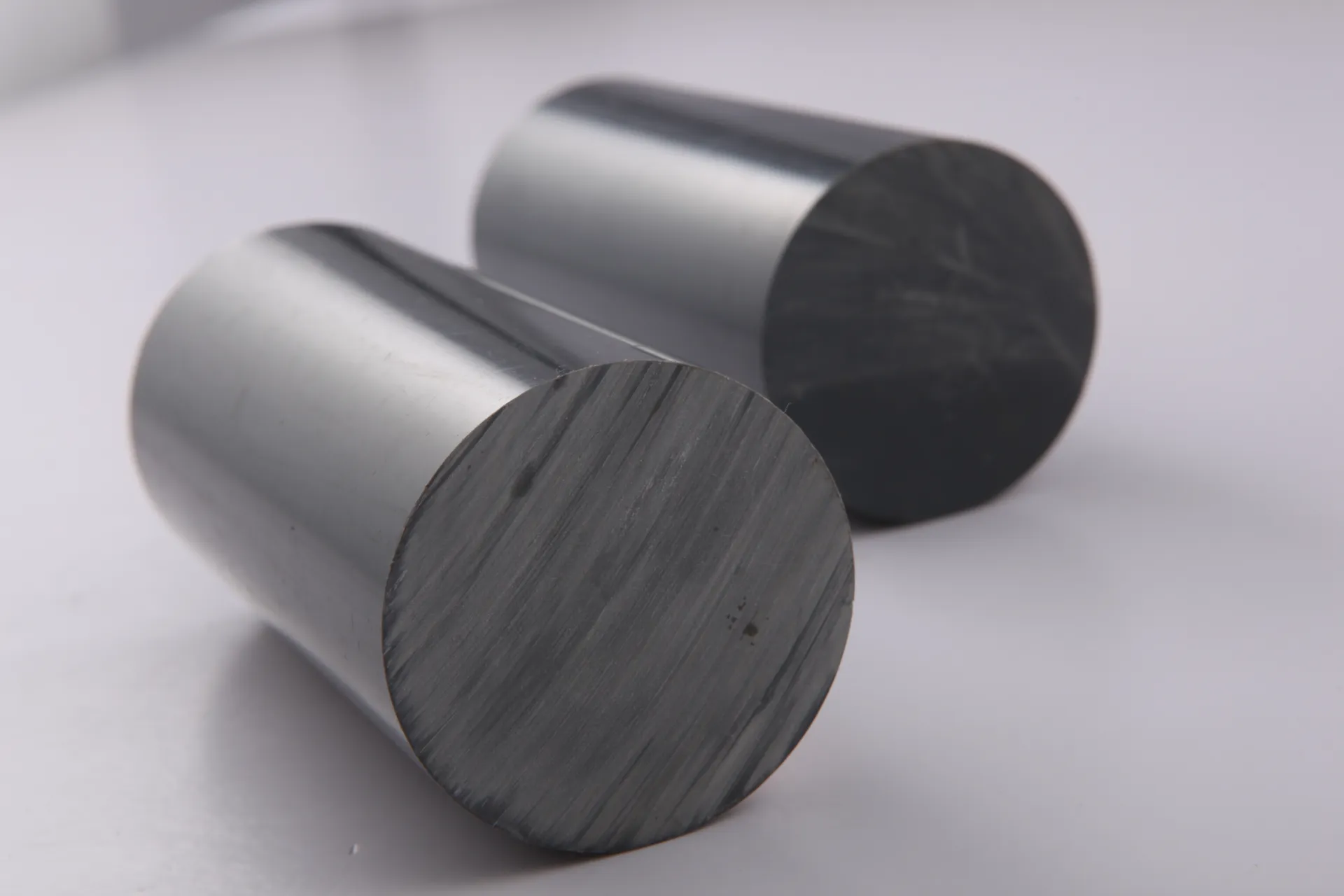

The production of high-quality PVC round rod is a sophisticated process, primarily relying on extrusion technology, which ensures consistent diameter, superior surface finish, and uniform material properties throughout the rod's length. This process begins with carefully selected Polyvinyl Chloride resin, often combined with stabilizers, lubricants, and pigments to achieve specific characteristics such as UV resistance or color. The raw PVC compound is fed into an extruder, where it is heated and melted, then forced through a die to form the desired round profile. This precise control over temperature and pressure is crucial for maintaining the material's integrity and achieving the specified dimensions and tolerances.

Following extrusion, the molten PVC round rod is carefully cooled in a water bath, which solidifies the material while preventing warping or deformation. This cooling phase is critical for dimensional stability. Once cooled, the rods undergo precision cutting to standard or custom lengths. Post-processing can involve further machining, such as CNC turning, to create highly precise components, threads, or complex geometries required for specialized applications. Each stage of the manufacturing process adheres to stringent quality control protocols, including inline laser measurement systems and manual inspections. Compliance with international standards such as ISO 9001 for quality management and ASTM (American Society for Testing and Materials) for material properties ensures that every PVC round rod meets the highest performance and durability benchmarks expected by industries like petrochemical, power generation, and water treatment.

Technical Specifications and Performance Data

Understanding the technical parameters of PVC round rod is essential for engineers and designers to ensure optimal material selection for specific applications. Polyvinyl Chloride, being a thermoplastic polymer, exhibits a unique combination of physical, mechanical, and electrical properties that make it highly suitable for demanding industrial environments. These properties are rigorously tested and documented, providing a reliable basis for material specification. Key performance indicators include tensile strength, which dictates the material's resistance to breaking under tension; flexural modulus, indicating its stiffness; and a low coefficient of thermal expansion, ensuring dimensional stability across varying temperatures.

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Density | ASTM D792 | g/cm³ | 1.38 - 1.42 |

| Tensile Strength | ASTM D638 | MPa (psi) | 50 - 65 (7250 - 9425) |

| Flexural Modulus | ASTM D790 | GPa (psi) | 2.4 - 3.1 (348000 - 450000) |

| Vicat Softening Point (VSP) | ASTM D1525 | °C (°F) | 75 - 85 (167 - 185) |

| Water Absorption (24 hrs) | ASTM D570 | % | 0.05 - 0.15 |

| Continuous Use Temperature | °C (°F) | 0 - 60 (32 - 140) | |

| Dielectric Strength | ASTM D149 | kV/mm | >15 |

These properties collectively contribute to the long service life of PVC round rod, often exceeding 50 years in optimal conditions, and its suitability for environments demanding high resistance to acids, alkalis, salts, and various organic solvents. The material's non-conductivity also makes it a safe choice for electrical applications, reducing the risk of short circuits or electrochemical corrosion. Furthermore, the light weight of PVC compared to traditional metallic materials translates into easier handling, reduced installation costs, and lower structural loads, contributing to overall project efficiency and cost-effectiveness.

Diverse Applications Across Industries

The versatility of PVC round rod allows its deployment across a multitude of industries, where it serves critical functions in various forms. In the chemical processing and petrochemical industries, it is extensively used for manufacturing corrosion-resistant components such as valve parts, pump impellers, tank linings, and fume extraction systems. Its inert nature prevents chemical degradation, ensuring long-term operational integrity and safety in environments exposed to aggressive reagents. Similarly, in water and wastewater treatment plants, PVC round rod finds applications in constructing filtration components, piping supports, and flow control mechanisms, benefiting from its resistance to biological growth and corrosion from treated and untreated water.

Beyond these sectors, PVC round rod is increasingly valued in electrical engineering and construction for insulation components, cable management systems, and conduit. Its high dielectric strength provides excellent electrical isolation, protecting sensitive equipment and personnel. In metallurgy and mining, where abrasive and corrosive conditions are prevalent, PVC rods are employed for wear plates, bushings, and guides. The material’s low friction coefficient and durability contribute to extended equipment life and reduced maintenance. The ease of machining PVC round rod also makes it a popular choice for prototyping and manufacturing custom parts in a wide range of general engineering applications, from consumer goods to specialized industrial machinery. Its adaptability makes it a compelling alternative to traditional materials, often offering enhanced performance at a lower total cost of ownership.

Lida Plastic: A Partner in Precision and Reliability

When selecting a supplier for PVC round rod, the choice of manufacturer significantly impacts the quality and performance of the final product. Lida Plastic distinguishes itself through a steadfast commitment to precision engineering, stringent quality control, and extensive industry experience spanning over two decades. Our manufacturing facilities are equipped with state-of-the-art extrusion lines and advanced testing laboratories, ensuring every PVC round rod meets and often exceeds global standards such as ISO 9001 and specific ASTM classifications for material properties and dimensional accuracy. Our dedication to quality is underscored by a zero-defect philosophy, supported by continuous process improvement and regular third-party audits.

Lida Plastic's authoritative position in the market is built on a foundation of long-term partnerships with leading enterprises across the globe, from large-scale industrial projects to specialized manufacturing operations. Our experience includes providing customized PVC round rod solutions for complex fluid handling systems in the petrochemical sector, precision components for semiconductor manufacturing equipment, and durable parts for agricultural machinery. Our long service tenure in the plastic industry has allowed us to accumulate unparalleled expertise, translating into superior product reliability and comprehensive customer support. We offer competitive lead times, typically 7-14 business days for standard orders, with expedited options available, ensuring your projects stay on schedule.

Tailored Solutions and Trustworthy Support

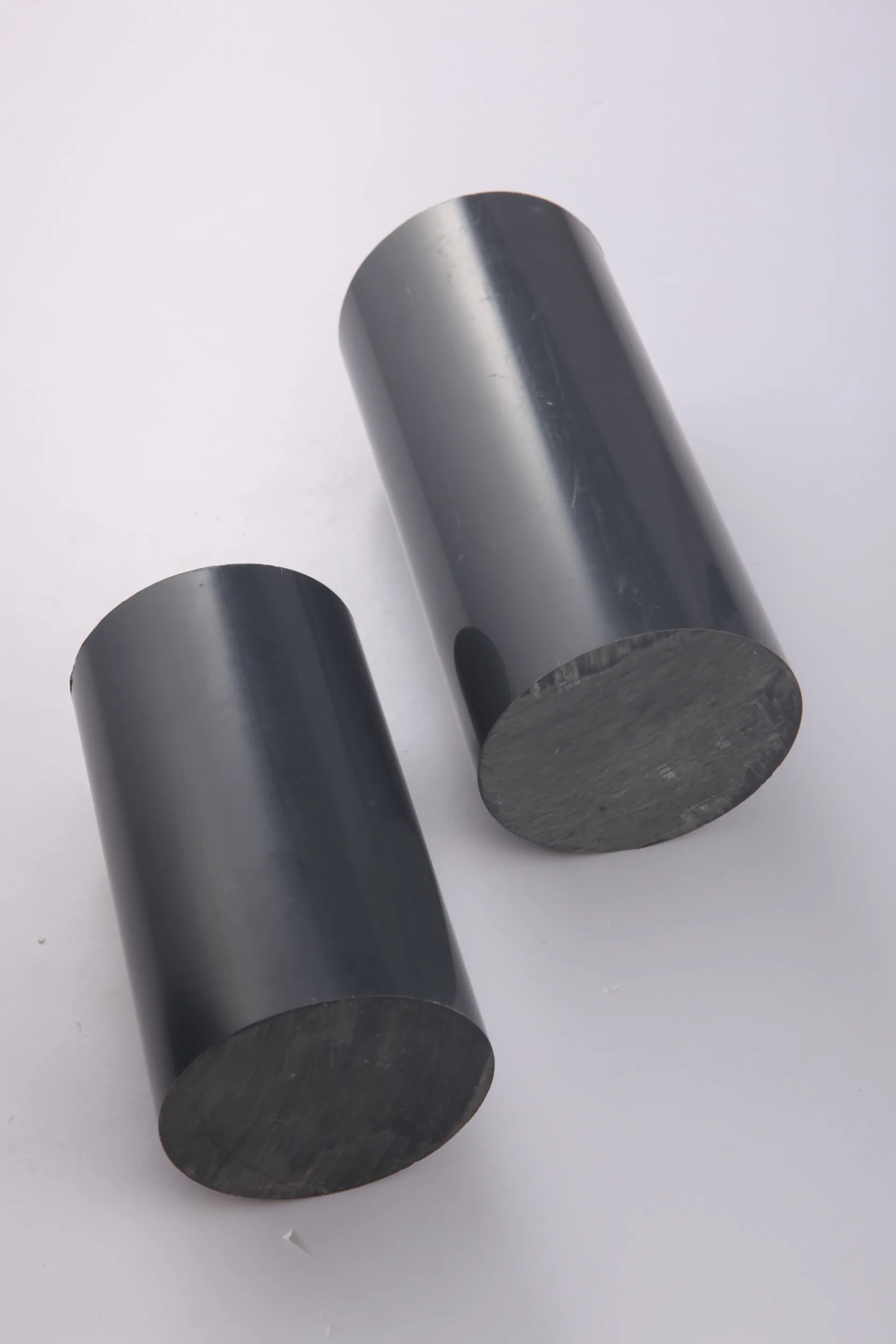

Recognizing that every industrial application has unique requirements, Lida Plastic offers extensive customization options for PVC round rod. This includes a wide range of diameters (from 6mm to 200mm) and lengths (up to 3000mm), specific color matching, and custom formulations to enhance properties like UV stability, flame retardancy, or chemical resistance for highly specialized uses. Our in-house technical team collaborates closely with clients from conceptualization to delivery, leveraging their deep knowledge of polymer engineering to develop solutions that precisely fit operational parameters and environmental challenges. We provide detailed material data sheets, comprehensive test reports, and engineering support to assist in material selection and application design, ensuring optimal performance and compliance.

Our commitment to customer satisfaction extends beyond product delivery. Lida Plastic offers a comprehensive warranty on all PVC round rod products, guaranteeing freedom from defects in material and workmanship. Our dedicated customer support team is available to address any inquiries regarding product specifications, order status, or technical assistance. We believe in building lasting relationships based on trust and transparency, providing clear communication regarding delivery schedules, pricing, and after-sales support. For any questions or to discuss your specific requirements, our FAQ section below provides immediate answers to common queries, or you can contact our sales engineers for personalized assistance, ensuring a seamless experience from inquiry to application.

Frequently Asked Questions (FAQ) about PVC Round Rod

Q1: What are the primary advantages of using PVC round rod over metallic rods?

PVC round rod offers superior chemical resistance to a broad spectrum of acids, alkalis, and salts, making it ideal for corrosive environments where metals would quickly degrade. It is also significantly lighter, easier to machine, electrically non-conductive, and often more cost-effective in terms of material and installation. Its excellent dielectric properties and resistance to galvanic corrosion are key benefits in certain applications.

Q2: What is the typical service life of a PVC round rod in industrial applications?

Under proper conditions and within its recommended temperature and chemical resistance limits, PVC round rod can have an exceptionally long service life, often exceeding 50 years. This longevity is due to its inherent resistance to degradation from moisture, chemicals, and biological attack. For specific applications, factors like continuous exposure to UV radiation or extreme temperatures should be considered, which may necessitate specialized PVC formulations.

Q3: Can PVC round rod be machined to precise tolerances?

Yes, PVC round rod is known for its excellent machinability. It can be easily cut, turned, drilled, milled, and welded using standard fabrication techniques. This allows for the creation of highly precise components with tight tolerances, making it suitable for intricate designs and custom parts required in various engineering and manufacturing processes.

Q4: What are the main quality standards or certifications for PVC round rod?

Reputable manufacturers adhere to international quality standards such as ISO 9001 for quality management systems. Product-specific properties are typically tested according to ASTM (American Society for Testing and Materials) standards, such as ASTM D1784 for rigid PVC compounds, which specifies requirements for various types and grades of PVC. Additionally, compliance with industry-specific regulations, like those for potable water contact or fire safety, may also be relevant.

Conclusion: The Enduring Value of PVC Round Rod

The continuous evolution of industrial requirements places a premium on materials that offer a blend of high performance, durability, and economic viability. The PVC round rod consistently meets these criteria, establishing itself as an indispensable material in a vast array of challenging applications. From corrosive chemical environments to critical electrical insulation, its inherent properties—including exceptional chemical resistance, high dielectric strength, and ease of fabrication—make it a superior choice over traditional materials. The longevity and low maintenance requirements of PVC round rod translate into significant long-term cost savings and enhanced operational efficiency for businesses.

As industries increasingly prioritize sustainable and resilient infrastructure, the role of materials like PVC round rod will only grow. Its ability to withstand harsh conditions, combined with ongoing advancements in manufacturing processes and material formulations, ensures its continued relevance and expansion into new applications. By partnering with experienced and authoritative manufacturers like Lida Plastic, industries can leverage the full potential of PVC round rod to drive innovation, improve safety, and achieve higher levels of productivity.

References

- European Council of Vinyl Manufacturers. "PVC: Properties & Applications." Accessed from ECVM official publications.

- Modern Plastics Encyclopedia. "Handbook of Plastics, Elastomers, and Composites." George S. Brady, Henry R. Clauser, John A. Vaccari, Editors. McGraw-Hill Professional, 2002.

- ASTM International. "Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds." ASTM D1784.

- The Plastics Industry Association (PLASTICS). "Plastics Industry Trends and Statistics." Accessed from PLASTICS.org.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025