Oct . 26, 2025 13:45 Back to list

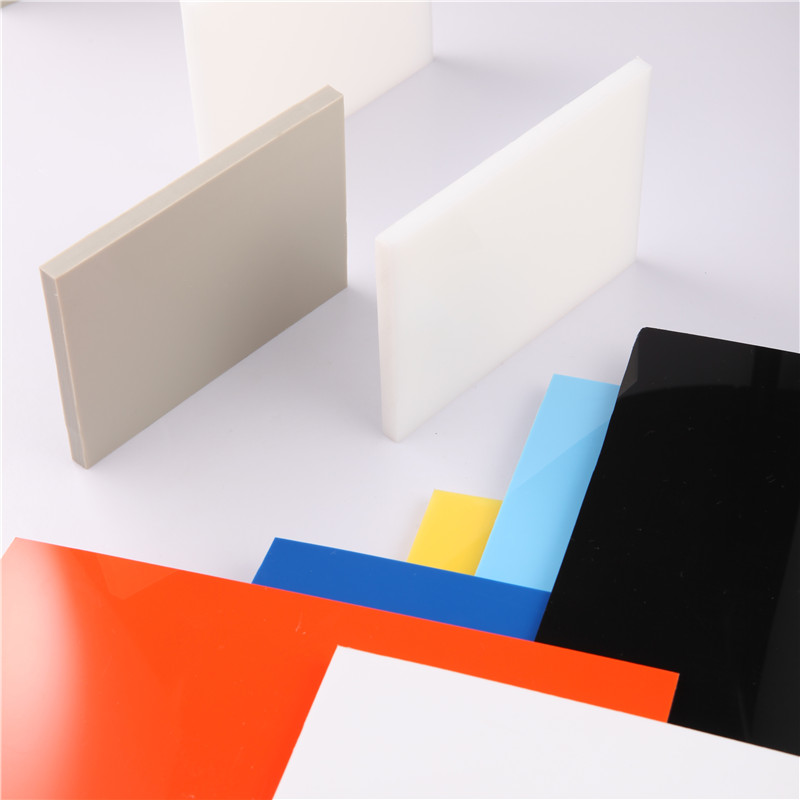

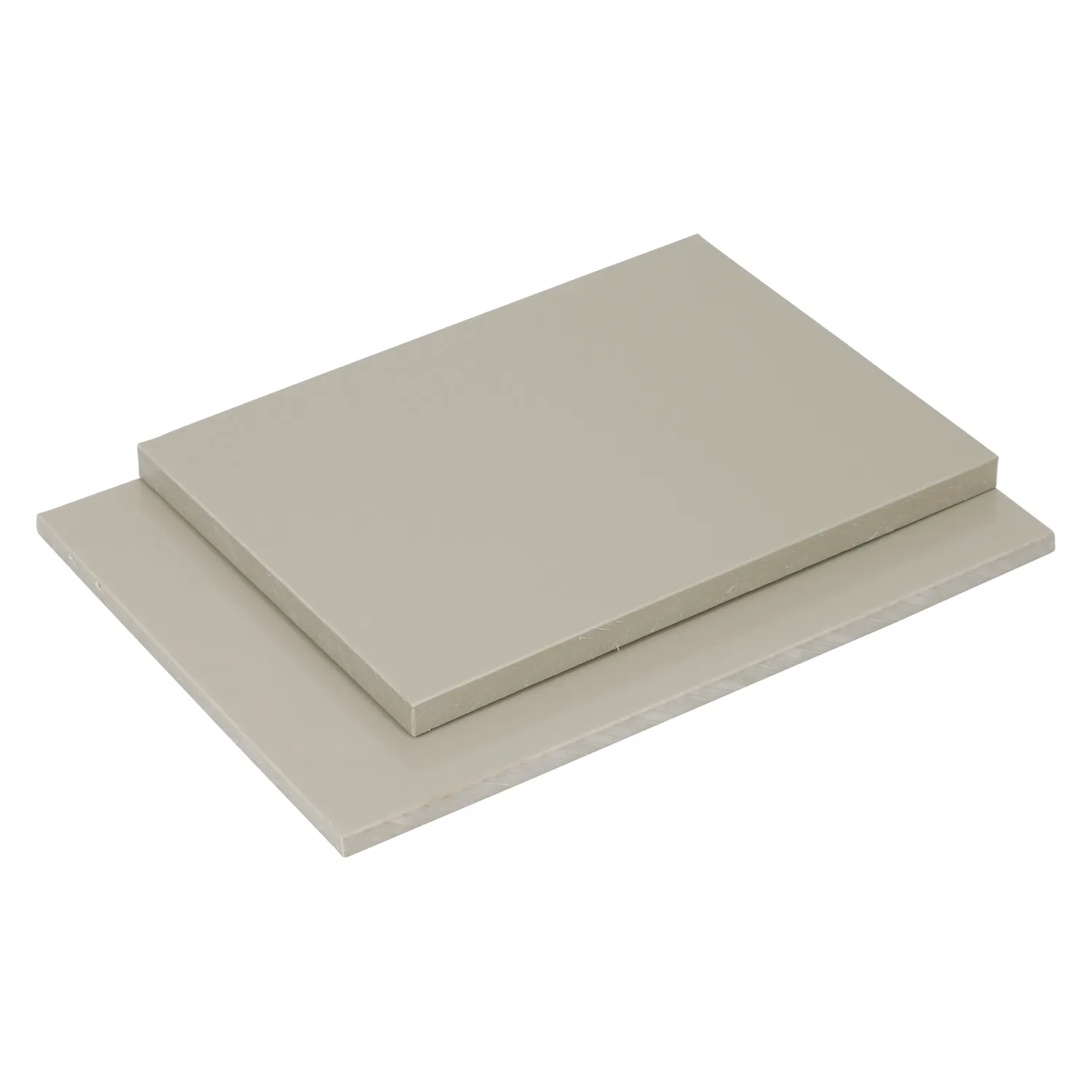

PP rigid sheet(glossy surface) - High Gloss, Durable

Why glossy PP rigid sheet is quietly taking over industrial plastics

If you work around tanks, ducts, housings, or cleanroom gear, you’ve heard the buzz about [PP Rigid Sheet(glossy Surface)]. It’s not just a commodity panel anymore; the glossy finish signals controlled extrusion, tighter tolerances, and frankly, nicer-looking fabrications. To be honest, the aesthetics matter when the plant manager walks through.

What’s trending

Two shifts I see on the ground: (1) chemical processors swapping heavier PVC for lighter PP to cut weight and avoid plasticizer concerns; and (2) OEMs speccing glossy surfaces for easier wipe-down in food and pharma spaces. Actually, many customers say the surface cleans quicker and shows fewer scuffs.

Technical snapshot

- Material: Polypropylene (PP) — homopolymer with 1–4% ethylene random copolymer for toughness.

- Surface: Glossy, polished roll finish.

- Colors: Natural, grey (RAL7032), black, light blue, yellow; custom RAL on request.

- Origin: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250.

| Spec | Typical/Range |

|---|---|

| Thickness | 2–40 mm |

| Width | 2–20 mm: 1000–2400 mm; 25–40 mm: 1000–1500 mm |

| Length | Any; cut-to-size service available |

| Density (ISO 1183) | ≈0.90 g/cm³ |

| Tensile strength (ISO 527) | ≈28–35 MPa |

| Elongation at break (ISO 527) | >200% (real-world use may vary) |

| Vicat softening (ISO 306) | ≈150–155 °C |

| Shore D (ISO 868) | ≈65–75 |

Process flow and QA

Resin selection → compounding with ethylene copolymer and UV/antioxidant package → extrusion → calendering on polished rolls (gloss control) → annealing to relieve stress → CNC trimming → inspection. Tests: density (ISO 1183), tensile/elongation (ISO 527), flexural (ISO 178), Vicat (ISO 306), gloss (ASTM D523), thickness tolerance (ISO 2768). Service life: indoors 10–15 years; outdoors 3–8 years (≈10+ with UV grade).

Where it fits

- Chemical tanks, pickling lines, fume ducts, scrubber internals.

- Food/pharma worktops, splash guards, cleanroom cart panels (the glossy face wipes fast).

- Machine housings, guards, conveyor sidewalls, orthotic blanks, signage backers.

Advantages vs PVC or HDPE: lower density, better chemical resistance to many acids/alkalis, weldability, and the [PP Rigid Sheet(glossy Surface)] cleans more easily than matte PP.

Vendor comparison (field notes)

| Vendor | Range | Lead time | Certs | Notes |

|---|---|---|---|---|

| Lida Plastic (Hebei) | 2–40 mm; widths to 2400 mm | ≈10–18 days | ISO 9001, RoHS/REACH | Strong cut-to-size, glossy control consistent |

| Generic Importer | 3–20 mm | ≈3–6 weeks | Varies | Spotty gloss uniformity; cheaper on small lots |

| Local Fabricator | Cut panels only | ≈2–7 days | Shop QA | Great turnaround; limited thickness/color |

Customization

Cut-to-size, CNC routing, welding rod supply, UV-stabilized grade, antistatic option (surface resistivity ≈10^9–10^11 Ω), and color matching. For hygiene builds, ask for low-bloom additive packages. The [PP Rigid Sheet(glossy Surface)] finish pairs nicely with solvent-free cleaning routines.

Real-world cases

Plating plant, NRW (DE): swapped 10 mm PVC liners for 8 mm [PP Rigid Sheet(glossy Surface)]; weight down ≈18%, weld seams passed ISO 527 strip tests, no leaks at 6 months. Supervisor liked the “easier wipe-off” gloss.

Food processor, MY: machine guards made from 6 mm glossy PP; weekly caustic wash, zero whitening after 9 months; edges CNC chamfered to reduce snagging.

Compliance and notes

Typical compliance: ISO 9001 production, RoHS/REACH substance limits; certain natural grades can conform to FDA 21 CFR 177.1520 (verify per batch). Flammability usually UL 94 HB. As always, qualify your application with in-house trials.

Citations

- ISO 527-1/2: Plastics — Determination of tensile properties.

- ISO 306: Plastics — Thermoplastic materials — Vicat softening temperature.

- ASTM D523: Standard Test Method for Specular Gloss.

- FDA 21 CFR 177.1520: Olefin polymers for food contact; REACH (EC) No 1907/2006.

-

Durable & Eco-Friendly HDPE Pipe Fittings | Lida Plastic

NewsNov.22,2025

-

HDPE Drip Pipe - Efficient Irrigation Solutions for Modern Agriculture

NewsNov.21,2025

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025