Oct . 08, 2025 22:45 Back to list

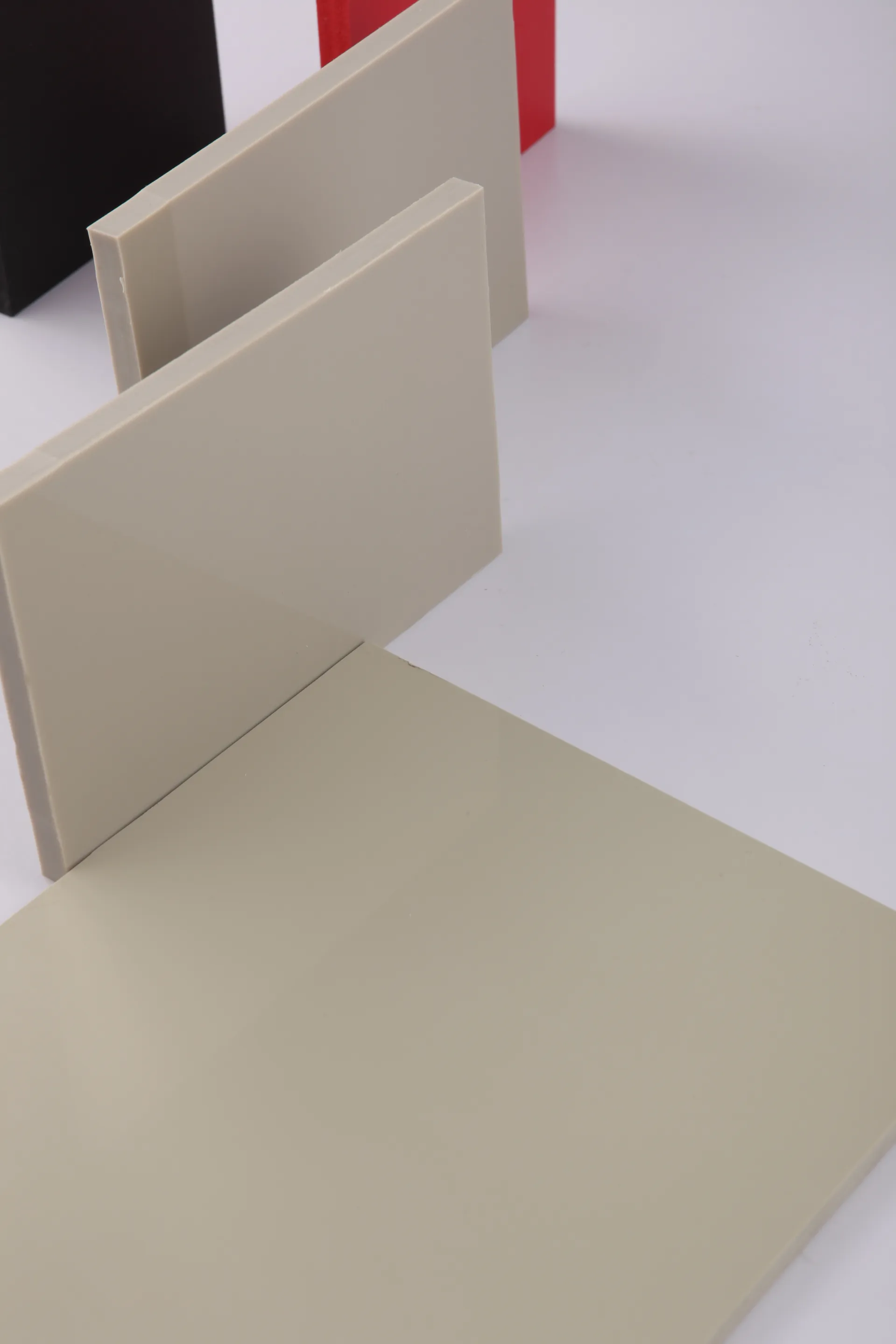

PP Fire Retardant Sheet with UL94 V-0 - Why Choose Ours?

What engineers are asking about PP fire-safe plastics this year

I’ve spent the past few months hopping between factories and design reviews, and one request keeps popping up: can we get a PP fire retardant sheet that’s halogen‑free, easy to fabricate, and properly tested? The short answer is yes—and, to be honest, demand is rising fast as teams move away from PVC in favor of lighter, cleaner polypropylene systems.

Why PP fire retardant sheet is trending

Lightweighting, halogen-free formulations, and tighter compliance (UL 94, FMVSS 302, ISO 3795) are shaping specs in HVAC plenums, battery plants, cleanrooms, and electrical enclosures. PP brings chemical resistance and weldability; the FR package adds the safety layer. Many customers say it’s easier to machine than expected—and surprisingly durable in corrosive air handling.

Core specifications (typical, lab-tested; real-world use may vary)

| Thickness | 2–30 mm |

| Standard sizes | 1220×2440 mm; 1000×2000 mm; 1500×3000 mm; cut-to-size available |

| Density | ≈0.98–1.05 g/cm³ (depends on FR loading) |

| Flammability | UL 94 V-0 at ≥3.0 mm; V-2 around 2.0 mm |

| Oxygen Index (LOI) | ≈28–32% |

| HDT @0.45 MPa | ≈95–105°C |

| Tensile strength (ASTM D638) | ≈28–35 MPa |

| Surface / Colors | Glossy or embossed; Natural, Grey (RAL7032), Black; custom colors on request |

Thickness-dependent; verify for your design and certification plan.

From pellets to panels: process overview

- Materials: PP resin + halogen‑free FR system (intumescent/mineral synergists) + UV stabilizers.

- Method: Twin‑screw compounding → sheet extrusion → calibrating → cooling → trimming.

- QC/tests: UL 94 burn, ISO 3795 / FMVSS 302, ASTM D638/D790/D256, dimensional check, color ΔE, weldability.

- Certifications/compliance: UL files as required, RoHS & REACH declarations; IEC glow‑wire on request.

- Service life: around 8–15 years in indoor industrial environments (chemicals and UV exposure affect results).

Where it’s used

HVAC plenums and fume ducts, battery module lines, chemical cabinets, cleanroom partitions, machine guards, electrical panel covers, and light‑duty tank cladding. Fabricators like that PP fire retardant sheet can be CNC‑cut, thermoformed, hot‑air welded, and solvent‑free bonded.

Vendor snapshot (selection)

| Vendor | FR system | UL 94 @3 mm | MOQ | Lead time | Custom color |

|---|---|---|---|---|---|

| Lida Plastic | Halogen‑free (intumescent) | V‑0 | Flexible | ≈10–15 days | Yes (RAL/Pantone) |

| Regional Brand X | Mineral‑filled | V‑0/V‑2 | Moderate | ≈3–4 weeks | Limited |

| Importer Y | Mixed FR | V‑2 | High | ≈5–6 weeks | Case‑by‑case |

Customization and origin

Surfaces: glossy or embossed. Colors: natural, grey RAL7032, black, plus project colors. Cut‑to‑size? Yes, routinely. Origin: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250. It seems that for many project managers, the quick cut plan is the make‑or‑break.

Two quick case notes

- Battery assembly line (SEA): swapped PVC for PP fire retardant sheet, cut part weight ≈25%, passed UL 94 V‑0 at 3 mm and FMVSS 302, maintained stiffness with ribbing. Field feedback after 10 months: “no warpage, easier cleaning.”

- Data hall cable cover retrofit (EU): specified grey RAL7032, embossed finish to hide scuffs; achieved LOI 30% and compliant burn rate under ISO 3795; installation time dropped because panels were lighter to handle.

Standards to check off

UL 94 for vertical burn (target V‑0 at 3 mm), ISO 3795 / FMVSS 302 for automotive interiors where relevant, IEC 60695 glow‑wire if used near energized parts, plus RoHS and REACH declarations. And yes, ask for tensile/flexural data (ASTM D638/D790) and HDT (ASTM D648) tied to the exact thickness you’ll use.

References:

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025