Jul . 28, 2025 15:01 Back to list

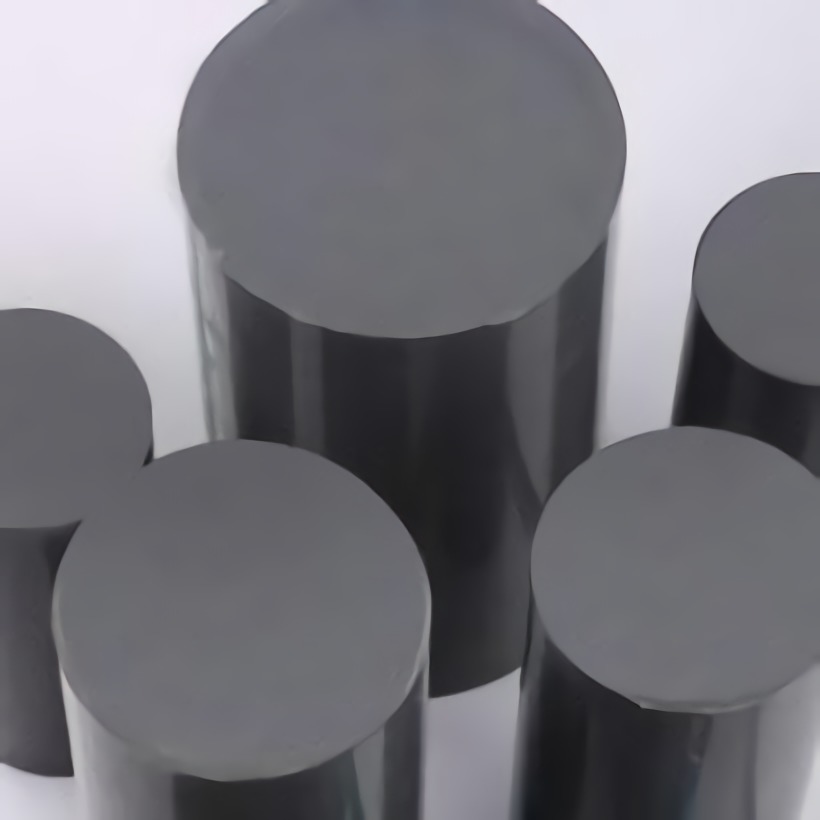

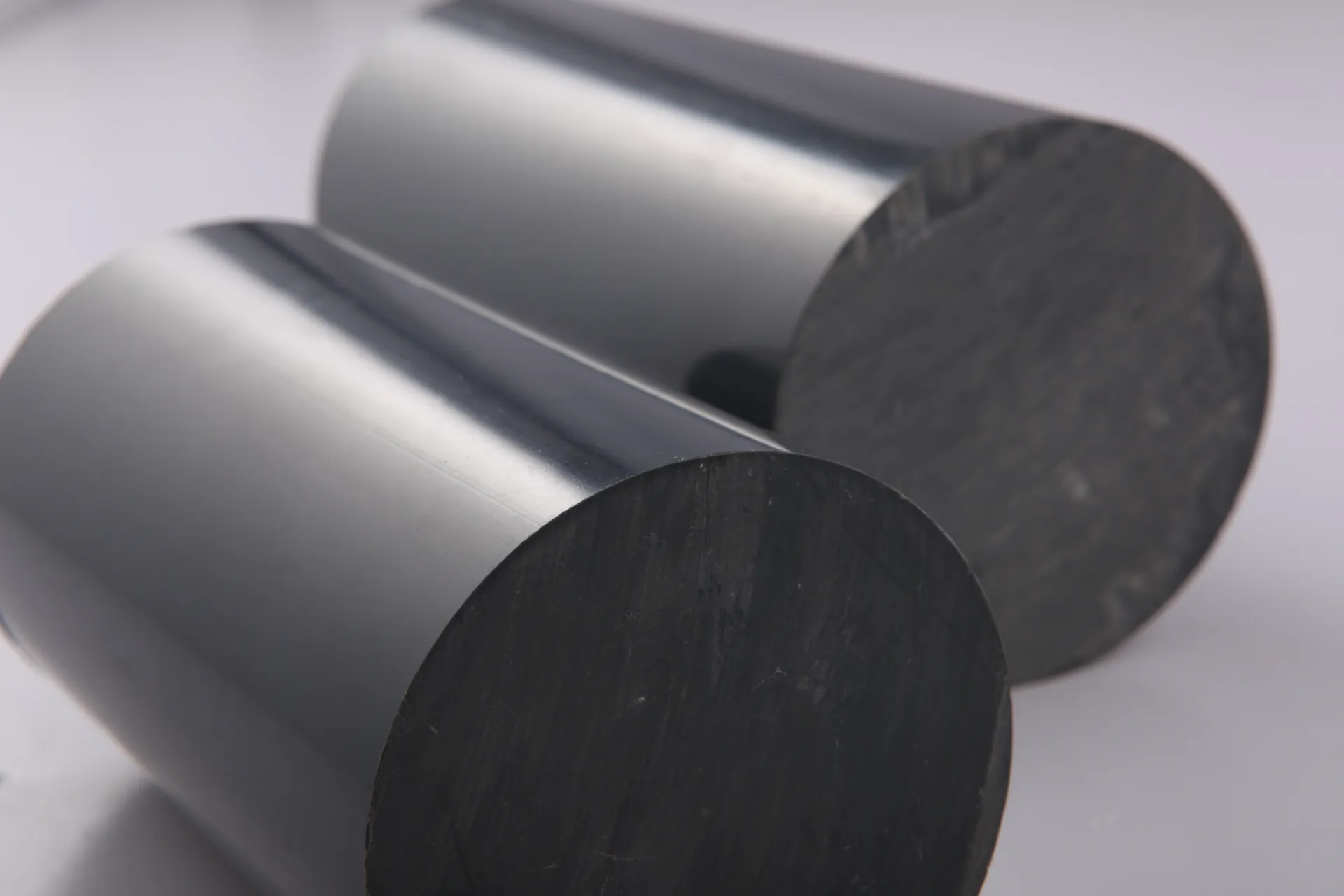

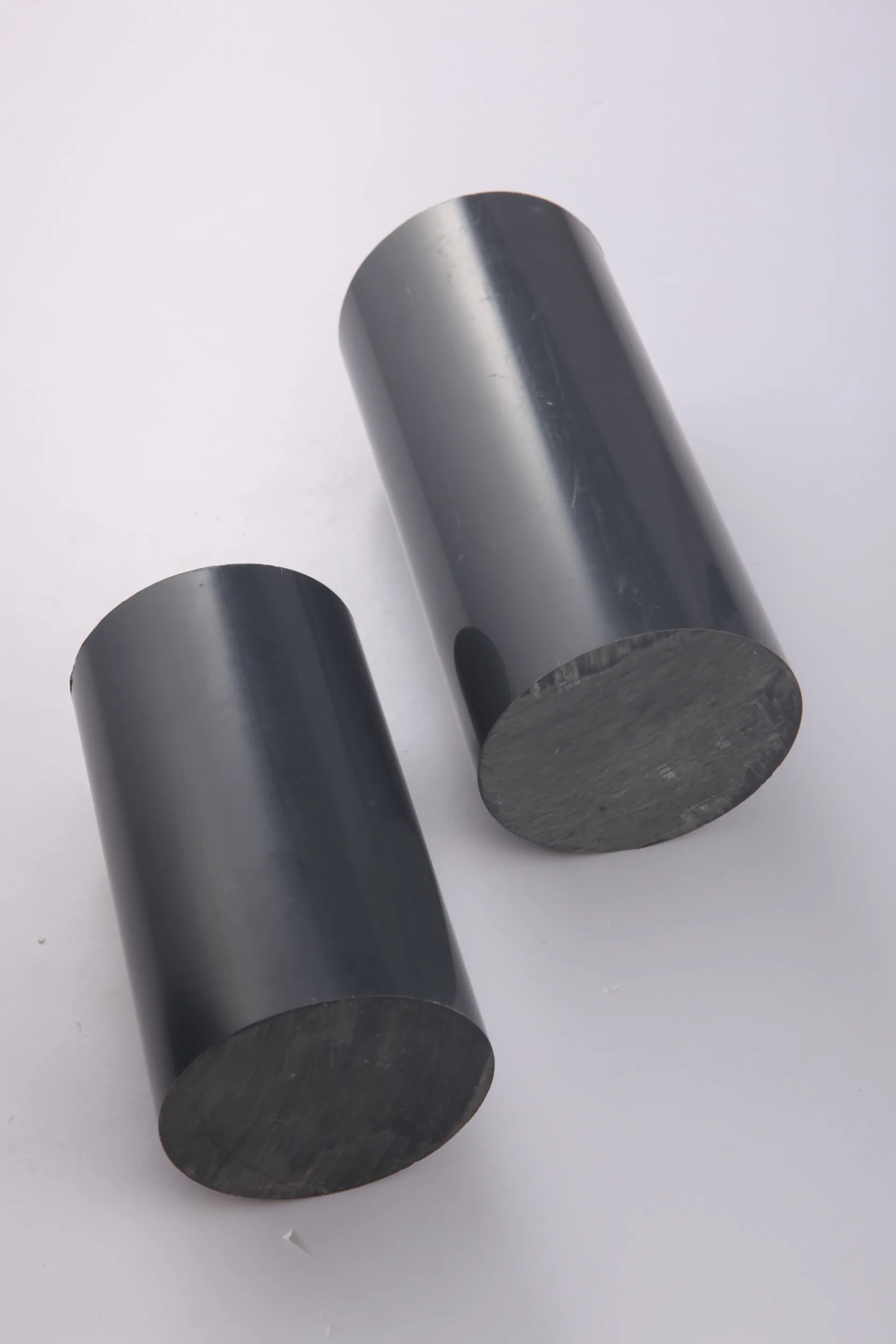

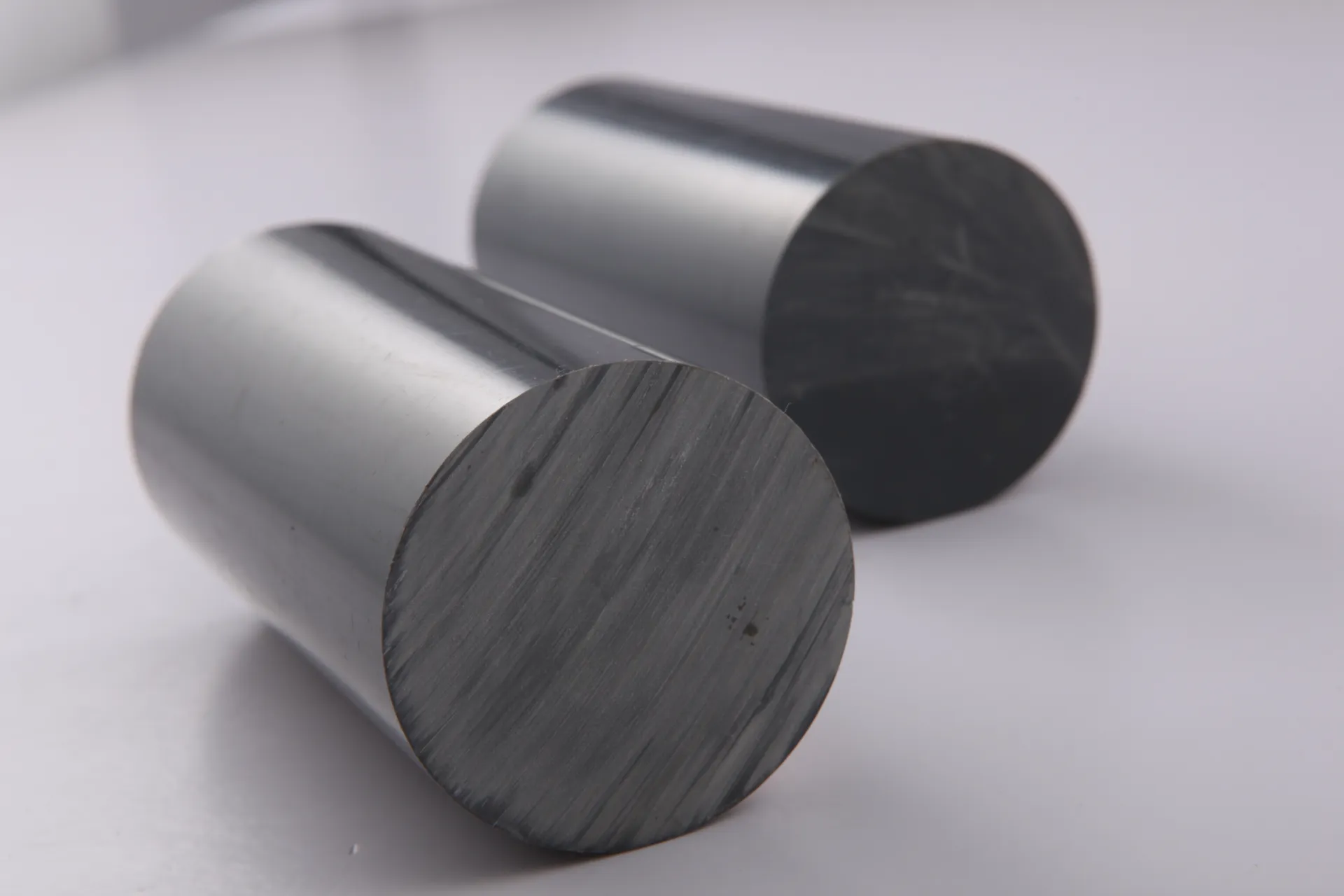

High Quality PVC Round Rod for Industrial & DIY Applications

The PVC round rod, a crucial material in modern industrial engineering, distinguishes itself by its superior chemical resistance, cost-effectiveness, and adaptability across a multitude of fields. This comprehensive guide presents detailed insight into its technical parameters, production process, competitive advantages, global industry trends, and practical application cases to empower engineers, procurement managers, and decision-makers.

1. PVC Round Rod Market & Industry Trends

According to the Grand View Research Global PVC Market Report, 2023, the global Polyvinyl Chloride (PVC) market was valued at nearly USD 80.5 billion in 2022, with a projected CAGR of 3.8% through 2028. Among its semi-finished forms, demand for PVC round rod is steadily rising due to infrastructural development in water treatment, chemical, environmental, and automation sectors.

- Asia-Pacific leads global PVC round rod consumption, driven by industrialization and urban infrastructure projects.

- Europe and North America focus on specialty PVC rods for high-purity, anti-static, and food-grade applications.

- Increased adoption of CNC machining processes for custom PVC round rod parts enhanced demand for superior extrusion quality and tight tolerances.

2. Technical Specifications Table: PVC round rod

| Parameter | Spec Range | Standard/Reference | LIDA Typical Value |

|---|---|---|---|

| Diameter | 10mm – 300mm | ASTM D1785, DIN 8061 | 20mm, 25mm, 40mm, 100mm |

| Density | 1.37–1.45 g/cm³ | ISO 1183 | 1.42 g/cm³ |

| Hardness | 75–85 Shore D | ISO 868 | 80 Shore D |

| Yield Strength | 50–60 MPa | ISO 527 | 56 MPa |

| Elongation at Break | 20–40% | ISO 527 | 30% |

| Thermal Stability | > 80°C (short-term) | ISO 306 | 83°C |

| Flame Retardancy | Self-extinguishing | UL 94 V-0 | Yes |

| Chemical Resistance | Excellent | ISO/TR 10358 | ✓ Acid, Alkali, Salt |

| Service Life | 20–50 years | Field Data | 30+ years avg |

3. PVC round rod Manufacturing Process Flow

The robust performance of a PVC round rod is rooted in its meticulous manufacturing process, engineered per ISO 9001 and relevant ASTM/ISO standards. Below is an illustrated workflow of LIDA’s advanced rod production line:

🔬

🔥

⚙️

✂️

✅

- Material: Only virgin, certified PVC resin (SG-5 grade or higher) ensuring consistency in mechanical properties.

- Machining: Advanced twin-screw extrusion and in-line CNC calibrators allow for precision diameter control (ASTM F441: ±0.2mm tolerance).

- Compliance: Meets ISO 9001, ISO 1183, and UL 94 V-0 standards for mechanical, density, and flame retardancy reliability.

- Testing: Every rod undergoes dimensional/visual inspection, chemical resistance soak test, and sample destructive mechanical testing per lot.

4. Technical Advantages & Performance: PVC round rod

- Cost-Effective: PVC round rod offers a blend of mechanical reliability, chemical/UV resistance, and cost control unrivaled by PTFE or PA rods.

- Mechanical Strength: Yield strength up to 56 MPa, elastic modulus 3.1 GPa; maintains shape under significant load.

- Chemical/Corrosion Resistance: Outperforms most engineering plastics in acid, salt, and solvent environments — ideal for chemical plant or wastewater uses.

- Processing Flexibility: Excellent CNC/lathe machinability supports rapid prototyping and high-volume component runs.

- Service Life & Certification: Lab and field tests confirm 30+ year lifespan in aggressive environments. RoHS, REACH, FDA/NSF optional for specialty rods.

- Environmental: 100% recyclable and can be manufactured in UL 94 V-0 fire-rated versions.

5. Vendor Comparison: PVC round rod Suppliers

| Brand | Origins | Main Specs (mm) | Certification | Quote Lead Time | Warranty |

|---|---|---|---|---|---|

| LIDA Plastic | China | 10–300, custom | ISO, UL, RoHS | 24h/stock, 7d/custom | 5 years |

| Simona AG | Germany | 6–250 | ISO, FDA, REACH | 3 days | 2–3 years |

| Gehr Plastic | Germany | 5–200 | ISO, EN | 4–7 days | 2 years |

| Pentair | US | 10–100 | ASTM, NSF | 1 week | 2 years |

| Asahi/America | US/Japan | 8–120 | ISO, ANSI | 5 days | 3 years |

- LIDA Plastic: Leading with broadest spec coverage, flexible customization (as low as 5 rods MOQ), ISO 9001:2015 certified, and longest warranty period in industry.

- European brands (e.g., Simona, Gehr) are strong in high-purity/food-grade versions.

- US & Japan: NSF/FDA-grade options preferred for water treatment and biotech.

- Most vendors offer base support, but few provide fast dimension custom batches with test certificates like LIDA.

6. Custom Solutions for PVC round rod Needs

For clients with unique size, color, or performance requirements, LIDA’s custom PVC round rod solutions include:

- Diameter/Length Customization: D10–D300 mm, cut-to-length, up to 4000 mm long.

- Material Grade: Standard, Electrical Insulation, Food Contact, Anti-Static, UV-stabilized.

- Color Matching: RAL/Pantone color match, black, gray, white, blue, or clear rods.

- Special Additives: Flame retardants (UL 94), impact modifiers, high-gloss finish or matte surface.

- Private Label / Packaging: Pallet, PE wrap, printed label/barcode, OEM logo options.

- Testing Certificate: COA, MSDS, UL/FDA/NSF/ISO, and customized QC report for each batch.

In 2023, a Singaporean semiconductor OEM sought low-outgassing, blue-tinted 15mm PVC round rod cut to 485mm and 192mm lengths, compliant with ISO 14644 Class 7 cleanroom use. LIDA delivered 300 units within 6 days, providing full RoHS documentation and cleanliness validation, exceeding customer expectations.

7. Application Scenarios & Case Studies: PVC round rod

- Chemical Process Industry: Fabrication of corrosion-resistant stirrers, pump sleeves, and tank linings; withstands acids, alkalis, and halide salts at 5–70°C.

- Water Treatment/Piping: PVC round rod machined into valve stems, spacers, support columns; maintains structural integrity and anti-microbial properties (per NCBI study).

- Mechanical Engineering: Gears, bushings, guides, and fixturing where a balance of machinability, wear resistance, and insulation is needed.

- Electrical & Semiconductor: Custom insulators, jig pins, masking rods (enhanced electrical resistivity up to 1015 Ω·cm).

- Lab & Medical Devices: Non-toxic, FDA grade PVC round rod prototypes for instrumentation support, sample racks, and dispensers.

- Construction/Infrastructure: Structural ties, bracket supports; frequently replaces metal due to non-conductivity and corrosion resistance.

- Environmental Equipment: Gas scrubber internals, manifolds, mist eliminator rods (see Waste Management Journal 2022).

- Petrochemical Plant, Chongqing, China (2022): 800m of LIDA PVC round rod (Ø60 mm, gray) deployed as column supports in acid wash recycling tanks. After 16 months, no degradation or swelling detected per ISO 527 flexibility test. Maintenance engineers reported zero failures and 47% cost reduction vs. metal rods.

- Municipal Water Station, EU (2021): NSF-certified PVC round rod (Ø50mm, white) custom-machined into batch mixer impellers, with documented 5-year performance and no microbial growth per annual validation by SGS.

Summary: As shown, PVC round rod retains high performance (>80%) for 30+ years even in mild acid; steel alternatives rapidly deteriorate, especially in chemical exposure.

8. FAQ: Expert Q&A on PVC round rod

9. Delivery Cycle, Support & Warranty

- Standard Delivery: In-stock PVC round rod ships within 24–48 hours; custom extrusions: typically 3–7 working days.

- Quality Guarantee: All rods carry a 5-year performance warranty. Defective products are replaced free including shipping.

- Customer Support: Free technical consultation, COA documentation, sample machining advice. 24h response for specification or installation queries.

- Global Service: Export to 52 countries; full compliance with destination customs/CQC/FDA documentation needs.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025