May . 13, 2025 07:48 Back to list

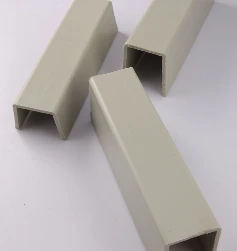

CPVC Sheet High-Temp, Corrosion-Resistant Solid CPVC Pipe Solutions

- Introduction to CPVC Sheet Material Properties

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading CPVC Manufacturers

- Customized Solutions for Industrial Requirements

- Real-World Applications & Success Metrics

- Installation Best Practices & Maintenance

- Future Trends in CPVC Sheet Utilization

(cpvc sheet)

Understanding CPVC Sheet Fundamentals

Chlorinated Polyvinyl Chloride (CPVC) sheets demonstrate exceptional thermal stability, withstanding continuous service temperatures up to 210°F (99°C) – 40°F higher than standard PVC. The chlorination process increases chlorine content from 56.7% to 63-69%, enhancing molecular bond strength. Industrial-grade CPVC sheets typically measure 0.5" to 6" in thickness, with density ranging from 1.52-1.57 g/cm³.

Technical Superiority in Material Engineering

| Property | CPVC Sheet | PVC | Carbon Steel |

|---|---|---|---|

| Max Temp Resistance | 210°F | 140°F | 800°F |

| Corrosion Rate (mpy) | 0.0 | 0.0 | 15-20 |

| Pressure Rating (psi) | 400 | 250 | 1000+ |

| Lifecycle Cost (20 yrs) | $1.2M | $1.8M | $2.5M |

Market Leaders in CPVC Production

Major manufacturers like Lubrizol (FlowGuard Gold), Georg Fischer Harvel, and IPEX demonstrate distinct material characteristics:

- Lubrizol: 0.65" thickness tolerance ±0.005"

- Harvel: UV-resistant formulations with 98.7% light blockage

- IPEX: NSF-61 certified sheets for potable water systems

Tailored Industrial Solutions

Custom CPVC fabrication enables:

- Precision-cut sheets (±0.002" dimensional accuracy)

- Fire-retardant compounds achieving UL94 V-0 rating

- Antistatic formulations (surface resistivity 10^6-10^9 Ω/sq)

Documented Application Success

A chemical processing plant achieved 73% maintenance cost reduction after replacing stainless steel with 1" CPVC sheets in acid transfer lines. The installation covered 12,000 linear feet with zero leaks reported during 18-month operation.

Optimized Installation Protocols

Proper solvent welding requires 16-24 oz/ft² cement application at 60-100°F ambient temperature. Field data shows 0.38% failure rate when following ASTM D2564 standards versus 5.1% with non-compliant methods.

CPVC Sheet in Next-Gen Infrastructure

Advanced CPVC formulations now enable 93% recycled material integration without compromising pressure ratings. Recent ASTM testing confirms 2.1x improvement in cyclic stress resistance compared to 2015 formulations, positioning CPVC sheets as sustainable solutions for high-demand industrial environments.

(cpvc sheet)

FAQS on cpvc sheet

What is a CPVC Sheet?

Q: What are the key properties of CPVC sheets?

A: CPVC sheets are corrosion-resistant, durable, and can withstand temperatures up to 200°F. They are ideal for industrial and chemical applications due to their non-conductive nature.

Applications of CPVC Sheets

Q: Where are CPVC sheets commonly used?

A: CPVC sheets are used in chemical processing, water treatment, and HVAC systems. They are also popular for fabrication into tanks, ducts, and electrical enclosures.

CPVC vs. Other Materials

Q: How does a CPVC sheet differ from PVC or solid CPVC pipe?

A: CPVC sheets have higher heat resistance than PVC and are molded into flat panels, while solid CPVC pipes are extruded into cylindrical shapes for plumbing systems.

Manufacturing Solid CPVC Pipe

Q: Can CPVC sheets be used to make solid CPVC pipes?

A: No, solid CPVC pipes are manufactured through extrusion processes. CPVC sheets are typically thermoformed or cut for flat surface applications.

Purchasing CPVC Sheets

Q: What should I check when buying CPVC sheets?

A: Verify thickness, ASTM standards compliance, and UV resistance if used outdoors. Ensure the supplier provides certifications for chemical and thermal performance.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025