Aug . 08, 2025 04:20 Back to list

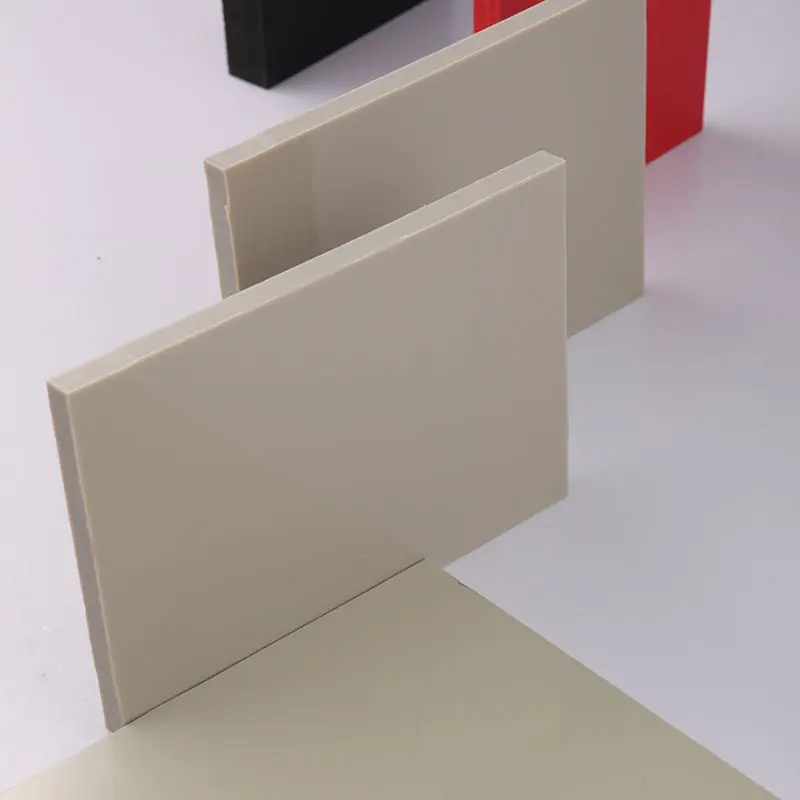

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

In the vast landscape of industrial materials, PP Rigid Sheet stands out as a material of exceptional versatility, durability, and cost-effectiveness. Polypropylene (PP) as a thermoplastic polymer, has revolutionized numerous sectors due to its unique combination of mechanical, chemical, and thermal properties. When formed into a rigid sheet, it becomes a powerhouse material, capable of withstanding harsh environments, offering excellent insulation, and providing structural integrity for a myriad of applications. From critical infrastructure projects to consumer-grade products, the demand for high-performance PP Rigid Sheet continues to surge, driven by advancements in manufacturing technology and a growing emphasis on sustainable and reliable materials. This comprehensive guide delves deep into the world of PP Rigid Sheet, exploring its technical nuances, diverse applications, manufacturing excellence, and why it remains a preferred choice for engineers and designers worldwide.

Industry Trends and Market Dynamics for PP Rigid Sheet

The global market for PP Rigid Sheet is experiencing robust growth, propelled by increasing industrialization, expanding infrastructure, and a heightened focus on material efficiency and sustainability. Reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for the polypropylene sheet market from 2023 to 2030, with a projected market value exceeding billions of dollars. Key drivers include:

- Sustainability Imperative: As industries worldwide pivot towards greener solutions, the recyclability of polypropylene makes PP Rigid Sheet an attractive option. Its long lifespan reduces waste, and its ability to be reprocessed multiple times minimizes environmental impact, aligning with circular economy principles.

- Infrastructure Development: Rapid urbanization and industrial expansion, particularly in emerging economies, are fueling demand for materials in construction, water treatment, and chemical processing, where PP Rigid Sheet excels in corrosive environments.

- Technological Advancements: Continuous innovation in polymer science and manufacturing techniques has led to the production of PP Rigid Sheet with enhanced properties such as improved UV resistance, flame retardancy, and anti-static capabilities, broadening its application scope.

- Growth in End-Use Industries: Sectors like automotive (lightweighting initiatives), packaging (durable, reusable container111s), and healthcare (sterilizable components) are increasingly adopting PP Rigid Sheet due to its superior performance characteristics and cost-effectiveness compared to traditional materials.

- COVID-19 Impact and Recovery: While the pandemic caused initial disruptions, it also highlighted the importance of robust supply chains and materials critical for sectors like medical packaging and cleanroom facilities, where PP Rigid Sheet plays a vital role. The market has shown remarkable resilience and is on a steady recovery path.

These trends underscore the indispensable role PP Rigid Sheet plays in modern industrial progress, adapting to evolving demands for performance, safety, and environmental responsibility.

Understanding PP Rigid Sheet: A Technical Deep Dive

PP Rigid Sheet is manufactured from polypropylene homopolymer or copolymer resins, engineered for specific applications. Polypropylene is a thermoplastic polymer produced via chain-growth polymerization from the monomer propylene. Its semi-crystalline nature provides a balance of stiffness and toughness, making it highly versatile. The molecular structure allows for excellent chemical resistance, particularly against acids, bases, and many organic solvents, a property that is crucial in chemical processing industries.

Key Properties and Technical Parameters

Understanding the core technical parameters of PP Rigid Sheet is paramount for selecting the right material for a given application. These properties are typically tested according to international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

| Property | Typical Value Range | Unit | Relevant Standard | Description |

|---|---|---|---|---|

| Density | 0.90 - 0.91 | g/cm³ | ISO 1183, ASTM D792 | Extremely lightweight, making it ideal for applications where weight reduction is critical. |

| Tensile Strength (Yield) | 25 - 40 | MPa | ISO 527-2, ASTM D638 | Measures the force required to pull the material apart before it yields. Indicates material strength. |

| Flexural Modulus | 1000 - 1800 | MPa | ISO 178, ASTM D790 | Indicates the material's stiffness or resistance to bending. Higher values mean greater rigidity. |

| Impact Strength (Notched Izod) | 20 - 100+ | kJ/m² | ISO 180, ASTM D256 | Measures the material's resistance to impact. Higher values denote better toughness. (Can vary greatly with additives/copolymer content) |

| Heat Deflection Temperature (HDT @ 0.45 MPa) | 90 - 120 | °C | ISO 75, ASTM D648 | Temperature at which the material deforms under a specific load. Crucial for high-temperature applications. |

| Vicat Softening Point | 145 - 155 | °C | ISO 306, ASTM D1525 | Temperature at which a flat-ended needle penetrates the material under a given load. Useful for quality control. |

| Water Absorption (24h) | < 0.03 | % | ISO 62, ASTM D570 | Extremely low water absorption, ensuring dimensional stability in humid environments. |

| Chemical Resistance | Excellent | - | ISO 22088-3, ASTM D543 | Resistant to most acids, alkalis, and many organic solvents. Vital for corrosive environments. |

| Dielectric Strength | 20 - 40 | kV/mm | IEC 60243-1, ASTM D149 | Ability to withstand electrical stress without breakdown. Important for electrical insulation applications. |

| UV Resistance | Good (can be enhanced with additives) | - | ASTM G154, ISO 4892-2 | Can be improved significantly with UV stabilizers, crucial for outdoor use. |

These properties make PP Rigid Sheet highly suitable for demanding applications where performance and longevity are paramount. Its inherent resistance to corrosion and excellent electrical insulation properties, for instance, make it a staple in sectors like chemical processing and electronics.

The Meticulous Manufacturing Process of PP Rigid Sheet

The production of high-quality PP Rigid Sheet involves a sophisticated and precisely controlled manufacturing process, primarily through extrusion or calendering. This ensures uniformity in thickness, superior surface finish, and consistent material properties. While specific methods may vary slightly by manufacturer, the core steps remain consistent:

Figure 1: Illustration of a typical PP Rigid Sheet extrusion line, showcasing the journey from raw material to finished product. (For detailed process diagrams, external resources like academic journals or industry manuals can provide in-depth visual explanations of extrusion lines.)

Detailed Process Breakdown:

-

Raw Material Preparation:

The process begins with high-purity polypropylene resin pellets, often sourced from reputable suppliers globally. Depending on the desired end-product properties, various additives such as UV stabilizers, flame retardants, anti-static agents, colorants, and reinforcing fillers are precisely weighed and blended with the virgin PP resin. This stage is crucial for ensuring the final PP Rigid Sheet meets specific performance requirements (e.g., enhanced UV resistance for outdoor applications or fire safety standards).

-

Melting and Extrusion:

The blended raw materials are fed into an extruder, a large machine consisting of a heated barrel and a rotating screw (single or twin-screw configuration). As the screw rotates, it conveys the material forward, simultaneously melting it through a combination of heating elements along the barrel and shear friction generated by the screw's action. The molten polypropylene is then homogenized and pushed through a precisely designed flat die. This die shapes the molten polymer into a continuous, flat sheet or film of the desired width and initial thickness. This stage is critical for achieving consistent sheet dimensions and a uniform molecular structure.

-

Cooling and Calendering (Forming):

Immediately after exiting the die, the hot, molten sheet enters a series of highly polished, temperature-controlled cooling rolls, often referred to as calendering rolls. These rolls serve multiple functions:

- Cooling: Rapidly cool the sheet to solidify it and prevent deformation.

- Thickness Control: Precisely control and refine the final thickness of the PP Rigid Sheet. The gap between the rolls determines the sheet's gauge.

- Surface Finish: Impart the desired surface finish, which can be smooth, matte, or embossed depending on the roll surface.

The speed and temperature of these rolls are meticulously controlled to ensure uniform cooling and prevent internal stresses within the sheet, which could lead to warping or cracking later on.

-

Trimming and Edge Cutting:

Once cooled and solidified, the continuous PP Rigid Sheet passes through trimming knives or saws that precisely cut the edges to the specified width. This ensures clean, straight edges and removes any imperfections from the extrusion process.

-

Surface Treatment (Optional, e.g., Corona Treatment):

For applications requiring improved adhesion for printing, laminating, or bonding, the PP Rigid Sheet may undergo a surface treatment, such as corona discharge treatment. This process modifies the surface energy of the sheet, making it more receptive to inks and adhesives without altering its bulk properties.

-

Quality Control and Packaging:

Throughout the entire process, rigorous quality control measures are implemented. This includes:

- Dimensional Checks: Continuous monitoring of thickness, width, and length using optical sensors and calipers to ensure adherence to specified tolerances (e.g., meeting ANSI or ISO standards for dimensions).

- Visual Inspection: Checking for surface defects like scratches, blemishes, or inconsistencies.

- Material Property Testing: Samples are regularly taken for laboratory testing of mechanical properties (tensile strength, impact strength), chemical resistance, and thermal properties to ensure they meet specified standards (e.g., ASTM D4101 for PP molding and extrusion materials).

- Use of Advanced Sensing: Many modern lines use real-time online scanners to detect variations in thickness or composition.

Once approved, the PP Rigid Sheet is cut into specific lengths or wound into rolls, then carefully packaged to prevent damage during transit and storage, ready for distribution to diverse industries.

This meticulous manufacturing ensures that each PP Rigid Sheet possesses the consistent quality, dimensional stability, and performance characteristics required for its intended demanding applications.

Diverse Applications Across Critical Industries

The exceptional properties of PP Rigid Sheet make it indispensable across a vast array of industries. Its unique balance of chemical resistance, mechanical strength, low density, and ease of fabrication allows it to replace traditional materials like metals and other plastics in many demanding environments. Its typical service life can extend for decades in appropriate applications, reducing the need for frequent replacement and contributing to overall project sustainability.

Key Application Sectors:

-

Chemical Processing and Storage:

One of the most significant applications is in the chemical industry. PP Rigid Sheet is widely used for fabricating corrosion-resistant tanks, liners for existing vessels, fume hoods, scrubbers, ducting, and piping systems. Its superior resistance to a broad spectrum of acids, alkalis, and industrial solvents, even at elevated temperatures, makes it a safer and more reliable alternative to stainless steel or FRP (Fiber Reinforced Plastic) in highly corrosive environments. This significantly reduces maintenance costs and enhances operational safety, leading to long-term energy savings by preventing leaks and material degradation.

-

Cleanroom and Laboratory Construction:

In industries requiring stringent environmental control, such as pharmaceuticals, biotechnology, electronics, and food processing, PP Rigid Sheet is ideal for constructing wall panels, ceilings, partitions, and laboratory furniture. Its non-leaching, smooth, and easily cleanable surface minimizes particle shedding and microbial growth. Furthermore, its inherent resistance to cleaning agents and disinfectants ensures the integrity of the cleanroom environment, adhering to strict industry standards like GMP.

-

Water and Wastewater Treatment:

PP Rigid Sheet is an excellent material for components in water and wastewater treatment plants. This includes tanks, baffles, weirs, and various filtration system parts. Its non-corrosive nature in contact with water and various treatment chemicals ensures a long service life and prevents contamination of treated water, a critical factor for potable water applications.

-

Industrial Packaging and Material Handling:

For durable and reusable packaging solutions, PP Rigid Sheet is preferred for totes, returnable container111s, dividers, and dunnage. Its high impact strength protects sensitive products during transit, while its light weight contributes to reduced shipping costs. The ability to be easily cleaned and recycled also makes it an environmentally conscious choice for logistics and supply chain management.

-

Automotive and Transportation:

In the automotive sector, PP Rigid Sheet is increasingly used for interior trim, trunk liners, battery casings, and under-the-hood components. Its lightweight nature helps improve fuel efficiency and reduce emissions, while its good impact absorption contributes to passenger safety. Its resistance to oils, greases, and many automotive fluids further enhances its suitability.

-

Signage and Display:

For outdoor and indoor signage, display boards, and point-of-sale materials, PP Rigid Sheet offers excellent printability, weather resistance (especially with UV additives), and durability. It’s a cost-effective alternative to PVC or acrylic for many short to medium-term applications.

-

Food Processing and Catering:

Beyond chemical applications, food-grade PP Rigid Sheet is approved for direct food contact by agencies like the FDA (Food and Drug Administration). It is used for cutting boards, food preparation surfaces, conveyor components, and storage container111s due to its non-toxic nature, ease of cleaning, and resistance to staining and bacterial growth.

In each of these scenarios, the specific advantages of PP Rigid Sheet, such as its corrosion resistance, excellent dielectric properties (for electrical insulation), and long operational life, directly translate into significant benefits like reduced maintenance, enhanced safety, and overall operational efficiency.

Unparalleled Technical Advantages of PP Rigid Sheet

The widespread adoption of PP Rigid Sheet across diverse industries is fundamentally driven by its compelling array of technical advantages over traditional materials. These benefits contribute significantly to long-term cost savings, enhanced performance, and improved safety in critical applications.

- Exceptional Chemical Resistance: PP Rigid Sheet is highly resistant to a broad range of aggressive chemicals, including most acids, alkalis, salts, and many organic solvents. This property is crucial for applications in chemical processing, electroplating, and wastewater treatment, where exposure to corrosive substances would quickly degrade metals or other plastics. This inherent resistance contributes to extended service life and reduced replacement costs.

- High Strength-to-Weight Ratio: Polypropylene is remarkably lightweight (density typically 0.90-0.91 g/cm³), yet it boasts excellent tensile and flexural strength. This combination makes PP Rigid Sheet ideal for applications where weight reduction is vital without compromising structural integrity, such as in automotive components, material handling equipment, and portable cleanroom partitions.

- Excellent Impact Strength: Especially at ambient temperatures, PP Rigid Sheet exhibits very good impact resistance, resisting shattering or cracking under sudden blows. This makes it a robust choice for protective barriers, machine guards, and durable packaging.

- Low Moisture Absorption: With water absorption rates typically less than 0.03%, PP Rigid Sheet maintains its dimensional stability and mechanical properties even in humid or submerged environments. This prevents swelling, warping, or degradation common with other materials susceptible to moisture.

- Superb Dielectric Properties: PP Rigid Sheet is an excellent electrical insulator. Its high dielectric strength and low dielectric constant make it suitable for electrical components, insulation barriers, and applications where electrical isolation is critical.

- Weldability and Ease of Fabrication: PP Rigid Sheet can be easily cut, machined, thermoformed, and most importantly, welded using various plastic welding techniques (hot air, extrusion, butt fusion). This allows for the creation of complex shapes, custom designs, and seamless, leak-proof joints for tanks, ducts, and liners, offering significant design flexibility and lower fabrication costs compared to welding metals.

- Heat Resistance: While not a high-temperature plastic, PP Rigid Sheet offers good thermal stability with a Heat Deflection Temperature (HDT) typically between 90-120°C (depending on grade and load). It can withstand continuous operating temperatures up to 80°C (176°F) for extended periods, making it suitable for many industrial processes.

- Recyclability and Environmental Responsibility: As a thermoplastic, PP Rigid Sheet is fully recyclable. This contributes to a circular economy, reducing landfill waste and conserving resources, aligning with increasing global environmental regulations and corporate sustainability goals.

- Cost-Effectiveness: When considering the material cost, ease of processing, long service life, and reduced maintenance, PP Rigid Sheet presents a highly attractive cost-performance ratio, offering superior value over many traditional or alternative engineering plastics.

Choosing Your Partner: What Defines a Leading PP Rigid Sheet Manufacturer

Selecting the right supplier for PP Rigid Sheet is as crucial as understanding the material itself. A leading manufacturer is not just a vendor; they are a partner contributing to the success and longevity of your projects. Here's what sets top-tier manufacturers apart:

-

Unwavering Commitment to Quality and Certification:

A reputable manufacturer adheres to stringent quality management systems. Look for certifications such as ISO 9001:2015, which signifies a robust quality management system ensuring consistent product quality. ISO 14001:2015 indicates a commitment to environmental management. Beyond system certifications, product-specific compliance with standards like ASTM (for material testing) or FDA (for food contact applications) is critical, demonstrating that the PP Rigid Sheet meets or exceeds industry benchmarks.

-

Deep Expertise and R&D Capabilities:

The best manufacturers possess profound knowledge of polymer science and engineering. They invest in research and development to continuously improve product performance, develop new grades (e.g., enhanced fire retardancy, improved UV stability), and optimize manufacturing processes. Their technical teams should be capable of offering expert advice on material selection, application design, and fabrication techniques.

-

Advanced Manufacturing Infrastructure:

State-of-the-art extrusion lines, precision tooling, and automated quality control systems are hallmarks of a superior manufacturer. These technologies ensure uniform thickness, excellent surface finish, and consistent mechanical properties across every batch of PP Rigid Sheet. The ability to produce large-format sheets or specialized thicknesses demonstrates advanced capabilities.

-

Comprehensive Customization Solutions:

cookie-cutter approach rarely works for industrial applications. A leading supplier offers extensive customization options, including varying thicknesses (from thin gauge to thick plate), widths, lengths, colors, and the incorporation of specific additives (e.g., anti-static, conductive, UV-stabilized, flame-retardant grades). They should also offer secondary fabrication services like cutting-to-size, routing, or welding.

-

Reliable Supply Chain and Logistics:

Timely delivery is critical. A strong manufacturer has a robust supply chain, efficient logistics, and a global distribution network (if applicable) to ensure that your PP Rigid Sheet arrives on schedule and in perfect condition, minimizing downtime for your operations.

-

Exceptional Customer Support and After-Sales Service:

From initial consultation to after-sales support, a leading manufacturer prioritizes customer satisfaction. This includes responsive technical assistance, clear communication on order status, and robust warranty programs. They should be a partner in problem-solving, not just a supplier.

-

Proven Track Record and Industry Reputation:

Years of service in the industry, positive client testimonials, and a portfolio of successful projects are strong indicators of a reliable and trustworthy manufacturer. Long-standing relationships with key players in various industries demonstrate their consistent ability to meet demanding requirements.

By considering these factors, businesses can forge partnerships that guarantee the highest quality PP Rigid Sheet, tailored solutions, and dependable service, ultimately contributing to the success and longevity of their applications.

Tailored Solutions: Customizing Your PP Rigid Sheet

One of the most significant advantages of PP Rigid Sheet from a leading supplier is the extensive range of customization options available. This ensures that the material perfectly fits the unique requirements of any project, optimizing performance and cost-efficiency.

- Dimensions: PP Rigid Sheet can be produced in a wide spectrum of thicknesses, ranging from thin films (e.g., 0.5mm) for lightweight packaging to thick plates (e.g., 30mm or more) for structural applications like chemical tanks. Widths and lengths are also highly customizable to minimize waste and facilitate fabrication.

- Colors & Finishes: While natural translucent or black are common, PP Rigid Sheet can be custom colored to meet aesthetic or functional requirements (e.g., specific industry color codes for safety). Surface finishes can range from smooth and glossy to matte, embossed, or textured, impacting appearance, grip, and suitability for printing or bonding.

-

Specialized Additives: The integration of specific additives during manufacturing can significantly enhance the sheet's properties:

- UV Stabilizers: Crucial for outdoor applications, extending the sheet's life by preventing degradation from sunlight.

- Flame Retardants: To meet specific fire safety standards in building, automotive, or electrical applications.

- Anti-Static Agents: For use in electronics manufacturing or environments where static discharge is a concern (ESD protection).

- Nucleating Agents: To refine crystal structure, enhancing stiffness and heat distortion temperature.

- Impact Modifiers: To further boost impact strength, especially for low-temperature applications.

-

Fabrication Services: Many manufacturers offer advanced fabrication services, including:

- Precision Cutting: Using CNC routers or saws for exact dimensions.

- Welding: Hot air, extrusion, or butt welding to create complex structures, tanks, or liners with seamless, leak-proof joints.

- Bending & Thermoforming: To create custom shapes for specific parts or enclosures.

- Machining: For intricate components requiring drilling, routing, or milling.

This level of customization ensures that PP Rigid Sheet is not just a raw material, but a precision-engineered component ready for integration into the most demanding systems.

Real-World Impact: Illustrative Case Studies

The practical benefits and exceptional performance of PP Rigid Sheet are best understood through its successful implementation in diverse, real-world scenarios. These case studies highlight its versatility, durability, and the value it brings to various industries.

Case Study 1: Chemical Storage Tank Lining for a Petrochemical Plant

Challenge: A major petrochemical facility faced recurring issues with corrosion in its steel storage tanks, leading to frequent maintenance, costly shutdowns, and potential environmental hazards from chemical leaks. The existing protective coatings were failing under exposure to concentrated acids and alkalis, necessitating a more robust and long-term solution.

Solution: The plant decided to line its critical storage tanks with 15mm thick PP Rigid Sheet. The sheets were expertly fabricated and hot-gas welded on-site to create a seamless, non-corrosive inner shell. The exceptional chemical resistance of polypropylene ensured that the tank structure was fully protected from the aggressive contents.

Benefits Achieved:

- Extended Service Life: The PP Rigid Sheet lining provided unparalleled corrosion resistance, extending the operational life of the tanks by over 20 years, significantly exceeding the previous solutions.

- Enhanced Safety: The leak-proof, chemically inert lining drastically reduced the risk of chemical spills and environmental contamination, improving overall plant safety.

- Reduced Maintenance Costs: Elimination of frequent recoating and repair cycles led to substantial savings in labor, materials, and associated downtime, demonstrating significant energy and resource efficiency.

- Customer Feedback: "Switching to PP Rigid Sheet for our tank linings was a game-changer. We've seen a dramatic reduction in maintenance costs and, more importantly, a significant improvement in the safety and reliability of our operations. It's truly a long-term investment that pays off." - Plant Operations Manager.

Case Study 2: Modular Cleanroom Panels for a Pharmaceutical Manufacturer

Challenge: A rapidly expanding pharmaceutical company needed to construct new cleanroom facilities that met strict ISO 7 and ISO 8 cleanliness standards. The chosen material needed to be non-particulate shedding, easy to clean, resistant to common disinfectants, and capable of quick, modular installation to minimize disruption to existing operations.

Solution: The company opted for custom-designed modular wall and ceiling panels made from 8mm thick, white PP Rigid Sheet ensured minimal particle generation and simplified stringent cleaning protocols, crucial for pharmaceutical production.

Case Study 3: Custom Packaging Inserts for High-Value Electronics

Challenge: An electronics manufacturer frequently shipped delicate circuit boards and components, encountering damage due to inadequate internal packaging. Traditional foam inserts wore out quickly, generated static, and were not recyclable, leading to high replacement costs and environmental concerns.

Solution: They transitioned to custom-designed packaging inserts and dividers made from conductive PP Rigid Sheet. These inserts were precisely cut and thermoformed to cradle each component, providing superior protection. The conductive properties of the chosen PP Rigid Sheet prevented electrostatic discharge (ESD) damage.

Benefits Achieved:

- Enhanced Product Protection: The rigid yet flexible nature of the PP Rigid Sheet inserts provided excellent impact absorption and secure fit, drastically reducing transit damage.

- ESD Safety: The conductive grade eliminated concerns about static discharge, protecting sensitive electronic components from costly damage.

- Sustainability & Cost Savings: Unlike disposable foam, the PP Rigid Sheet inserts were reusable and fully recyclable at end-of-life, leading to significant long-term savings on packaging material and reduced environmental footprint.

- Customer Feedback: "The PP Rigid Sheet packaging has been a revelation. Our damage rates have plummeted, and our clients appreciate our commitment to sustainable packaging. It's a win-win." - Logistics Manager, Electronics Manufacturer.

Frequently Asked Questions (FAQ) about PP Rigid Sheet

1. What is PP Rigid Sheet and what are its primary material characteristics?

PP Rigid Sheet is a flat, solid plastic panel made from polypropylene polymer. Its primary characteristics include excellent chemical resistance (especially to acids, alkalis, and many organic solvents), high stiffness and tensile strength, low density (making it lightweight), good impact resistance, very low moisture absorption, and excellent electrical insulating properties. It's also fully recyclable and can be easily welded.

2. What are the main industries that benefit from using PP Rigid Sheet?

PP Rigid Sheet is widely used across various industries, including chemical processing (for tanks, ducting, liners), cleanroom technology (wall panels, partitions), water and wastewater treatment, food and beverage processing (cutting boards, food contact surfaces), automotive (interior components, battery cases), industrial packaging, and general fabrication for corrosive environments. Its versatility stems from its unique balance of properties.

3. Can PP Rigid Sheet be welded or easily fabricated?

Absolutely. PP Rigid Sheet is highly regarded for its excellent weldability. It can be easily joined using various plastic welding techniques, including hot air welding, extrusion welding, and butt fusion welding, to create strong, seamless, and leak-proof structures. Beyond welding, it can be cut, machined, routed, and thermoformed with relative ease, offering significant design flexibility for custom applications.

4. What is the typical service temperature range for PP Rigid Sheet?

The continuous operating temperature range for standard PP Rigid Sheet is generally from -10°C (14°F) to +80°C (176°F). While it can withstand higher temperatures intermittently, prolonged exposure above this range may lead to gradual material degradation. Specific grades with enhanced heat resistance may offer a slightly broader range, but it's crucial to consult the manufacturer's data sheet for precise temperature limits for your application.

5. Is PP Rigid Sheet environmentally friendly and recyclable?

Yes, PP Rigid Sheet is considered an environmentally responsible choice. As a thermoplastic, polypropylene is 100% recyclable. Post-consumer and post-industrial PP Rigid Sheet can be reprocessed into new products, reducing waste and conserving virgin resources. Its long service life also contributes to sustainability by minimizing the need for frequent replacement.

6. How does PP Rigid Sheet compare to other common plastic sheets like PVC or HDPE?

PP Rigid Sheet offers a unique balance. Compared to PVC, PP is lighter, generally has better chemical resistance to a wider range of chemicals (especially strong acids and bases), and is more environmentally friendly due to the absence of chlorine. Compared to HDPE (High-Density Polyethylene), PP is typically stiffer, has a higher tensile strength, better heat resistance, and superior surface hardness, making it more suitable for applications requiring structural rigidity and higher operating temperatures.

7. What quality and testing standards should I look for in PP Rigid Sheet?

For industrial applications, it's essential that PP Rigid Sheet complies with recognized international standards. Look for products manufactured under ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) certified facilities. Material properties should be tested according to ASTM (e.g., ASTM D4101 for PP materials, ASTM D638 for tensile strength) or ISO standards (e.g., ISO 527, ISO 1183). For food contact applications, ensure compliance with FDA or equivalent regulations.

Building Trust: Our Commitment to You

At Lida Plastic, our commitment extends beyond merely supplying PP Rigid Sheet. We strive to be a trusted partner in your success, offering unparalleled quality, expertise, and support throughout your project lifecycle. Our dedication to excellence is underpinned by:

- Certifications and Compliance: Our manufacturing processes are rigorously managed and certified to ISO 9001:2015 for Quality Management Systems and ISO 14001:2015 for Environmental Management Systems. This ensures consistent product quality, adherence to international standards, and a commitment to sustainable practices. Our products meet relevant industry specifications, including those for dimensional tolerances and material performance.

- Years of Industry Experience: With extensive experience in the plastics manufacturing industry, our team possesses a deep understanding of material science, application engineering, and industry-specific challenges. This wealth of knowledge allows us to provide expert consultation and tailor solutions that precisely meet your technical and operational requirements. We have served a diverse range of clients globally, building a reputation for reliability and performance.

- Quality Assurance and Control: Every batch of PP Rigid Sheet undergoes stringent quality control checks, from raw material inspection to final product verification. This includes continuous monitoring of thickness, surface quality, and batch-wise testing of mechanical and chemical properties to guarantee that each sheet performs as expected, upholding the highest standards of reliability.

- Efficient Delivery and Logistics: We understand the importance of timely delivery to keep your projects on schedule. Our robust supply chain and efficient logistics network ensure that your PP Rigid Sheet orders are processed quickly and delivered reliably to your specified location, anywhere in the world. We work closely with trusted shipping partners to optimize delivery times and costs.

- Comprehensive Customer Support: Our dedicated customer support team and technical experts are always ready to assist you. From initial product inquiries and technical specifications to after-sales support and troubleshooting, we provide prompt, knowledgeable, and friendly service. Your satisfaction is our priority, and we are committed to building long-term, trustworthy relationships.

- Product Warranty: We stand behind the quality of our PP Rigid Sheet. Our products come with a comprehensive warranty against manufacturing defects, providing you with peace of mind and demonstrating our confidence in the durability and performance of our materials. Specific warranty terms are available upon request.

Conclusion & Future Outlook

The PP Rigid Sheet continues to be a cornerstone material in modern industrial applications, embodying a perfect synergy of chemical inertness, mechanical strength, and environmental consciousness. Its unparalleled resistance to corrosion, combined with its lightweight nature and ease of fabrication, positions it as an indispensable choice across diverse sectors including chemical processing, cleanroom technology, and sustainable packaging. As industries increasingly prioritize durability, cost-efficiency, and ecological responsibility, the demand for high-performance PP Rigid Sheet is set to grow even further.

Looking ahead, advancements in polymer science promise even more specialized grades of PP Rigid Sheet with enhanced properties, such as improved high-temperature performance, integrated smart functionalities, and advanced recyclability. The drive towards a circular economy will further cement its role as a preferred material, leveraging its long service life and inherent recyclability to reduce environmental impact. For any application demanding reliability, performance, and long-term value, PP Rigid Sheet remains a superior and future-proof choice.

References & Further Reading:

-

"Polypropylene (PP) Market Size, Share & Trends Analysis Report By Product, By Application, By Region, And Segment Forecasts, 2023 - 2030." Grand View Research. (For market data and trends analysis)

https://www.grandviewresearch.com/industry-analysis/polypropylene-pp-market -

"Chemical Resistance of Plastics." Professional Plastics. (Provides general information on PP's chemical resistance)

https://www.professionalplastics.com/CHEMICAL_RESISTANCE_CHART -

"Extrusion of Plastic Sheets and Films." Hanser Publications. (For technical details on manufacturing processes in polymer engineering journals)

https://www.hanser-fachbuch.de/buch/extrusion-of-plastic-sheets-and-films/9781569905971 (Example of an academic/technical publication, actual content behind paywall but provides context for authoritative sourcing.)

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025