Cov khoom siv raw

Lub npe ntawm cov khoom siv raw: chlorinated polyvinyl chloride (Lus Askiv Chlorinated Polyvinyl Chloride), tseem hu ua vinyl chloride. Chlorinated resin yog ib yam tshiab ntawm engineering yas. Tom qab chlorination ntawm PVC resin, qhov tsis sib xws ntawm molecular bonds, polarity, solubility ntawm cov resin, thiab tshuaj stability nce, yog li txhim kho cov khoom kub tsis kam, acid kuj, alkali, ntsev, oxidizer corrosion. Cov khoom siv hluav taws xob ntawm cov lej thermal deformation kub tau txhim kho, cov ntsiab lus chlorine tau nce los ntawm 56.7% mus rau 63-69%, thiab Vicat softening kub tau nce los ntawm 72-82 ℃, nce mus rau 90-125 ℃.Yog li ntawd, CPVC yog ib hom tshiab engineering yas nrog dav daim ntawv thov prospects.

Cov txheej txheem ntau lawm thiab muaj peev xwm

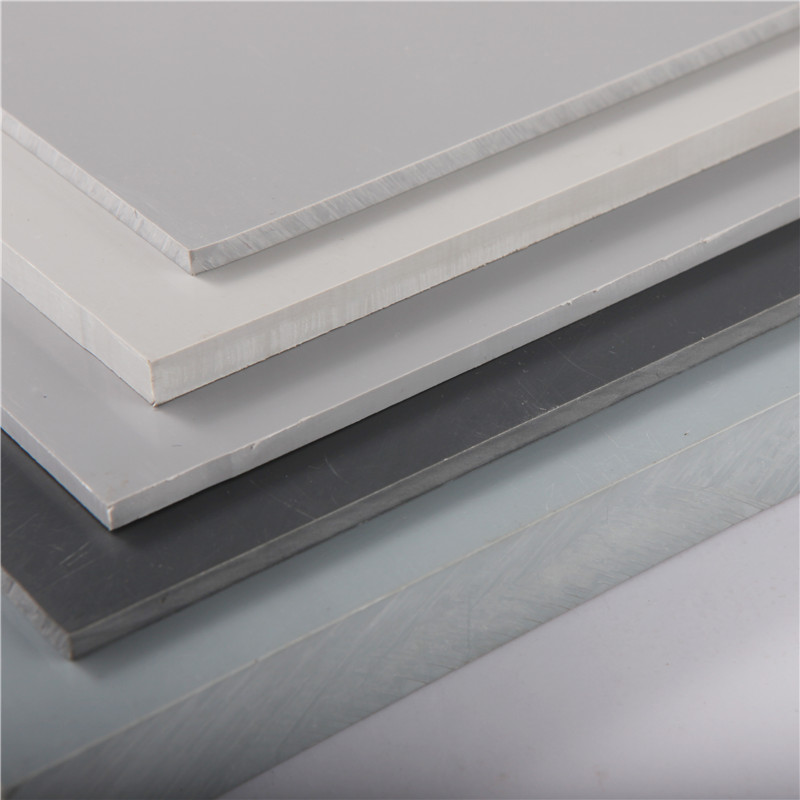

CPVC phaj yog chlorinated polyvinyl chloride raws li raw cov ntaub ntawv, piv ntawm raw cov ntaub ntawv los ntawm thawj qhov hnyav ntsuas rau hauv qhov sib tov, thawj kauj ruam yog kub tov thiab nplawm kom ncav cuag ib tug kub thiab txias ces mus rau txias mix stirring, tom qab sib tov mus rau noj. system, tom qab ntawd los ntawm cov tswv tsev plasticizing rau hauv pwm, ntsia hlau extrusion molding tom qab peb-yob inferior du, ces nkag mus rau hauv lub koom haum pab, raws li qhov kev txiav txim qhov ntau thiab tsawg txiav daim ntawv kawg.

Muaj peev xwm

Peb muaj 20 PVC Sheet ntau lawm kab nrog txhua xyoo ntau lawm ntawm 30000tons, thiab 3 CPVC daim ntawv ntau lawm kab nrog txhua xyoo ntau lawm ntawm 3000tons.

Yam ntxwv

High Vicat softening kub;

Cov tshuaj zoo heev thiab corrosion kuj;

Zoo heev thermo-stability kev ua tau zoo;

Yooj yim rau fabricate, weld lossis tshuab;

High rigidity thiab superior zog;

Txhim khu hluav taws xob rwb thaiv tsev;

Tsawg flammability, self-extinguishing.

Daim ntawv thov

CPVC daim ntawv tsuas yog siv nyob rau hauv kev lag luam tshuaj rau chlorine electrolysis, electroplating, ntawv kev lag luam, semiconductors kev lag luam thiab huv-chav siv tshuab, xws li Lab equipments, Etching equipments, semiconductor processing equipments, tshuaj storing tanks, roj tso tsheb hlau luam, storing tank rau brewing dej, acid lossis alkali ntau lawm yees, kua qaub los yog alkali ntxhua khaub ncaws thiab lwm yam.