Oct . 14, 2025 03:55 Back to list

PVC Rigid Sheet(UV Stabilized) - Weatherproof, Cut-to-Size

PVC Rigid Sheet(UV Stabilized) is a key solution in the manufacturing industry, specifically within the plastic product industry and the manufacturing of plastic sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Rigid Sheet(UV Stabilized) Overview

- Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) Overview

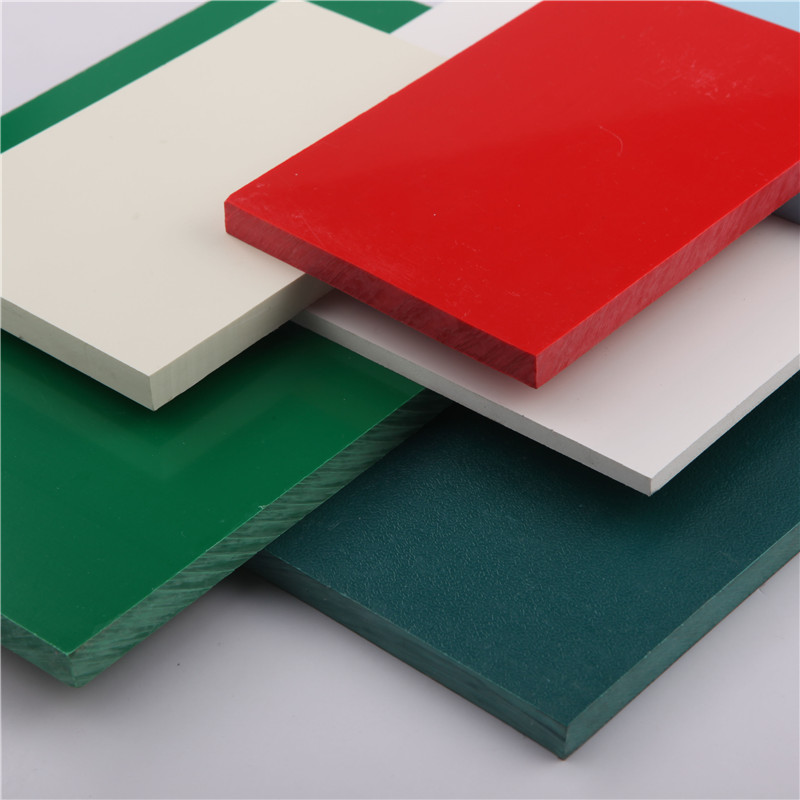

PVC Rigid Sheet(UV Stabilized) is an engineered polyvinyl chloride sheet formulated with UV stabilizers to resist yellowing, chalking, and embrittlement under prolonged sunlight exposure. For B2B decision makers in the plastic product industry, this substrate balances mechanical rigidity, surface quality, and outdoor durability—making it a reliable choice for structural panels, protective covers, and print-ready displays. Produced via precision extrusion and calendering, it offers consistent gauge control, low water absorption, dimensional stability, and strong resistance to many acids, alkalis, and salts.

Typical characteristics include smooth or matte finishes, excellent printability, weldability, and machinability for CNC routing, cutting, and bonding. While exact specifications depend on grade, users commonly select service temperatures suited to moderate outdoor conditions and specify custom thicknesses, widths, and colors for application fit. Baoding Lida Plastic Industry Co., Ltd is a dependable manufacturer known for stable formulations, tight tolerances, and responsive technical support—helping OEMs and fabricators integrate UV-stabilized PVC sheets into demanding production environments with confidence.

Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

Across the manufacturing of plastic sheets, pipes, and profiles, PVC Rigid Sheet(UV Stabilized) delivers a strong cost-to-performance ratio. It is widely used for outdoor signage and displays, building cladding and soffits, electrical and telecom enclosures, protective machine guards, chemical process covers, HVAC ducting components, and agricultural and marine partitions. Compared with non-UV formulations, the stabilized sheet retains color, gloss, and impact strength for longer service life in sun-exposed installations.

Key advantages include:

- Weatherability: UV stabilization reduces degradation, extending replacement cycles.

- Printability and surface quality: Supports screen, digital, and vinyl applications with minimal prep.

- Fabrication flexibility: Easy to cut, rout, bond, weld, and thermoform with predictable outcomes.

- Chemical and moisture resistance: Suitable for industrial and coastal environments.

- Dimensional stability: Maintains flatness and tolerances for tight-fit assemblies.

Baoding Lida Plastic Industry Co., Ltd leverages industry expertise to customize color, finish, and sizing, and to align additive packages with application needs. Consistent supply, quality control, and application guidance help OEMs shorten development cycles and reduce scrap, making the company a strategic partner for manufacturers scaling production with UV-stable PVC sheets.

Cost, Maintenance & User Experience

Total cost of ownership is where PVC Rigid Sheet(UV Stabilized) excels. While initial pricing may be comparable to standard rigid PVC, the UV stabilization mitigates premature fading and brittleness, lowering replacement and field service costs. Fabricators benefit from predictable machining behavior, clean edges, and reliable adhesion/weld performance, which reduce rework and increase throughput. For brand owners and asset managers, extended outdoor life preserves visual quality and structural integrity, supporting higher ROI over multi-year deployments.

Recommended maintenance is straightforward: periodic cleaning with mild detergent and water; avoid abrasive pads or aggressive solvents. For assemblies, allow for thermal expansion and use UV-rated adhesives and sealants where relevant. Customers in the plastic product industry commonly report consistent color matching across batches, minimal warpage during processing, and steady surface energy for printing and film lamination—resulting in fewer production interruptions and a smoother end-user experience.

Working with Baoding Lida Plastic Industry Co., Ltd further streamlines procurement through reliable lead times, protective packaging to minimize transit damage, and documentation support (e.g., technical data and conformance statements) to accelerate qualification and onboarding.

Sustainability & Market Trends in manufacturing

Manufacturers are prioritizing materials that balance durability with environmental responsibility. By extending outdoor service life, PVC Rigid Sheet(UV Stabilized) reduces replacement frequency and associated waste. The material’s recyclability and compatibility with controlled regrind use support circularity initiatives where infrastructure exists. Evolving regulatory frameworks—such as RoHS and REACH—are reinforcing the shift toward heavy-metal-free stabilizer systems, traceable supply chains, and transparent material disclosures.

Baoding Lida Plastic Industry Co., Ltd positions itself as a forward-looking partner by focusing on stable, UV-resistant formulations that meet compliance expectations and by promoting process efficiency to reduce scrap and energy use. The company’s application guidance helps customers right-size material thickness and grade for performance without over-specifying—an effective path to lowering embodied resources while maintaining quality. As outdoor infrastructure, renewable energy assets, and branded installations expand globally, demand for long-life, UV-stable rigid PVC continues to grow, offering a resilient and cost-effective path for B2B manufacturers.

Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) delivers dependable outdoor performance, strong chemical resistance, and excellent fabrication and printing characteristics—an ideal combination for the plastic product industry and the manufacturing of plastic sheets, pipes, and profiles. Backed by the manufacturing expertise of Baoding Lida Plastic Industry Co., Ltd, buyers gain consistent quality, customization options, and technical support that shorten time to market and lower lifecycle costs.

Contact us: email: lidaplastic@ldsy.cn

Visit our website: https://www.lidaplastic.com

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025

-

Durable & Eco-Friendly HDPE Pipe Fittings | Lida Plastic

NewsNov.22,2025

-

HDPE Drip Pipe - Efficient Irrigation Solutions for Modern Agriculture

NewsNov.21,2025

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025