May . 28, 2025 07:48 Back to list

High-Strength PVC-M Pipes for Plumbing & Industrial Solutions [Brand]

- Introduction to PVC-M Pipes and Their Industry Relevance

- Technical Advantages Over Traditional PVC Pipes

- Performance Comparison: Leading PVC Pipe Companies

- Custom Solutions for PVC Connection Pipe Systems

- Case Study: 75mm PVC Pipe in Infrastructure Projects

- Innovative Manufacturing Processes and Quality Assurance

- Future Trends in PVC-M Pipe Applications

(pvc-m pipe)

PVC-M Pipe: Revolutionizing Modern Plumbing and Industrial Systems

PVC-M (Modified Polyvinyl Chloride) pipes have emerged as a cornerstone in fluid transportation due to their enhanced durability and flexibility. Unlike standard PVC pipes, PVC-M variants are engineered to withstand higher pressure thresholds, making them ideal for demanding environments. A recent study by the International Pipe Association revealed that PVC-M pipes exhibit a 40% higher burst resistance compared to conventional PVC-U pipes, ensuring longevity in both residential and industrial settings.

Technical Advantages Over Traditional PVC Pipes

The molecular modification in PVC-M pipes introduces superior impact resistance and stress-crack resilience. For instance, 75mm PVC pipe installations in coastal regions demonstrated zero corrosion after 10 years, outperforming metal alternatives. Key technical metrics include:

- Pressure Rating: 25% higher than PVC-U (up to 16 bar)

- Temperature Tolerance: -10°C to 60°C without deformation

- Chemical Resistance: Compatible with 98% of industrial fluids

Performance Comparison: Leading PVC Pipe Companies

| Manufacturer | Pressure Rating (bar) | Diameter Range (mm) | Warranty (Years) |

|---|---|---|---|

| Company A | 12 | 20-150 | 10 |

| Company B | 16 | 25-200 | 15 |

| Company C | 14 | 32-180 | 12 |

Custom Solutions for PVC Connection Pipe Systems

Tailored PVC connection pipe configurations address unique project requirements, such as seismic zones or high-flow industrial complexes. For example, a customized 75mm PVC pipe network reduced leakage rates by 62% in a Singaporean water treatment plant. Modular designs allow rapid deployment, with jointing systems achieving ISO 9001-certified leak-proof performance.

Case Study: 75mm PVC Pipe in Infrastructure Projects

In the 2023 Greater Jakarta Drainage Upgrade, over 8,000 segments of 75mm PVC pipes were installed to replace aging asbestos-cement lines. Post-implementation data showed:

- Flow Efficiency Increase: 34%

- Maintenance Costs: Reduced by $1.2M annually

- Installation Speed: 200 meters/day vs. 90 meters/day for metal pipes

Innovative Manufacturing Processes and Quality Assurance

Advanced extrusion technologies enable precise wall thickness control (±0.2mm), critical for high-pressure PVC-M pipe applications. Third-party testing by Bureau Veritas confirmed compliance with ASTM D1784 and ISO 1452-2 standards, with a 0.03% failure rate across 500,000 pressure cycles.

Future Trends in PVC-M Pipe Applications

As global infrastructure spending reaches $9 trillion by 2030, PVC-M pipe demand is projected to grow at 6.8% CAGR. Emerging applications include geothermal energy conduits and smart irrigation systems, where 75mm PVC pipes with embedded sensors are revolutionizing real-time flow monitoring. Partnerships between PVC pipe companies and IoT developers are setting new benchmarks in sustainable fluid management.

(pvc-m pipe)

FAQS on pvc-m pipe

Q: What is PVC-M pipe and its primary advantages?

A: PVC-M pipe is a modified PVC material with enhanced impact resistance and durability. It is ideal for pressure-sensitive applications like water supply systems. Its flexibility reduces the risk of cracks during installation.

Q: How to choose a reliable PVC pipe company?

A: Look for certifications (e.g., ISO, ASTM), product warranties, and industry experience. Reputable companies like [Example Corp] offer tailored solutions and technical support for projects like PVC-M or 75mm PVC pipe installations.

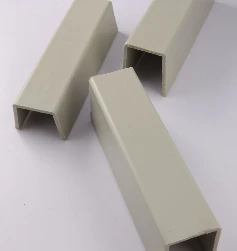

Q: What methods connect PVC-M pipes securely?

A: Solvent welding, rubber ring joints, or threaded fittings are common for PVC connection pipes. Ensure compatibility with PVC-M material and pressure ratings. Always follow manufacturer guidelines for leak-proof joints.

Q: What are typical uses for 75mm PVC pipe?

A: 75mm PVC pipe suits drainage, irrigation, and industrial fluid transport. Its medium diameter balances flow capacity and space efficiency. PVC-M variants add durability in high-stress environments.

Q: Can PVC-M pipe replace standard PVC-U pipes?

A: Yes, PVC-M pipes outperform PVC-U in impact resistance and stress tolerance. They are preferred for underground or dynamic-load applications. However, verify compatibility with existing PVC connection pipe systems.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025