Feb . 15, 2025 04:50 Back to list

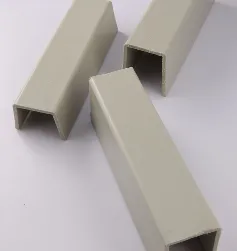

rigid pvc sheet

When seeking high-performance, durable materials, rigid PVC sheets are among the top choices due to their versatility and robustness. These sheets, prized for their unique properties, are increasingly utilized in various industries, including construction, advertising, and interior design. As an expert in material science, I can attest to their advantages in practical applications.

From an environmental standpoint, rigid PVC has made significant strides in sustainability. Modern manufacturing processes incorporate recycling practices, reducing waste and environmental impact. As demand for green building materials rises, PVC manufacturers have responded by adopting eco-friendly measures that align with global sustainability standards, making PVC sheets a responsible choice for eco-conscious industries. In terms of design flexibility, rigid PVC does not disappoint. Available in various thicknesses, colors, and finishes, these sheets can be custom-fabricated to meet virtually any design specification. Their fire retardant properties add another layer of safety, crucial for applications requiring stringent compliance with fire safety regulations. For those in the realm of product fabrication, rigid PVC sheets offer unmatched versatility. Their ease of thermoforming and cutting allows manufacturers to craft intricate designs quickly and efficiently. Whether used for producing point-of-sale displays, protective barriers, or household goods, the material consistently delivers on functionality and aesthetics. Expertise in handling and installing rigid PVC sheets is paramount to maximize their benefits. Professionals familiar with the thermal and physical properties of PVC can ensure optimal performance and longevity of the installed products. This expertise translates into reliable service and high-quality end products, reinforcing the value provided to customers. In conclusion, rigid PVC sheets stand as a testament to innovation in material science, combining affordability, durability, and versatility. Industries worldwide trust this material for its ability to meet and exceed modern engineering and design challenges. With their proven track record and continued advancements in sustainability, rigid PVC sheets are set to remain an indispensable resource in a multitude of applications, underscoring their rightful place in the pantheon of essential building materials.

From an environmental standpoint, rigid PVC has made significant strides in sustainability. Modern manufacturing processes incorporate recycling practices, reducing waste and environmental impact. As demand for green building materials rises, PVC manufacturers have responded by adopting eco-friendly measures that align with global sustainability standards, making PVC sheets a responsible choice for eco-conscious industries. In terms of design flexibility, rigid PVC does not disappoint. Available in various thicknesses, colors, and finishes, these sheets can be custom-fabricated to meet virtually any design specification. Their fire retardant properties add another layer of safety, crucial for applications requiring stringent compliance with fire safety regulations. For those in the realm of product fabrication, rigid PVC sheets offer unmatched versatility. Their ease of thermoforming and cutting allows manufacturers to craft intricate designs quickly and efficiently. Whether used for producing point-of-sale displays, protective barriers, or household goods, the material consistently delivers on functionality and aesthetics. Expertise in handling and installing rigid PVC sheets is paramount to maximize their benefits. Professionals familiar with the thermal and physical properties of PVC can ensure optimal performance and longevity of the installed products. This expertise translates into reliable service and high-quality end products, reinforcing the value provided to customers. In conclusion, rigid PVC sheets stand as a testament to innovation in material science, combining affordability, durability, and versatility. Industries worldwide trust this material for its ability to meet and exceed modern engineering and design challenges. With their proven track record and continued advancements in sustainability, rigid PVC sheets are set to remain an indispensable resource in a multitude of applications, underscoring their rightful place in the pantheon of essential building materials.

Share:

Next:

Latest news

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025