Jun . 07, 2025 23:12 Back to list

Durable PP & HDPE Roofing Sheets Corrosion-Resistant

- Material properties and performance advantages

- Technical specifications and durability metrics

- Leading manufacturer comparison analysis

- Architectural customization possibilities

- Industry-specific application solutions

- Installation best practices and lifecycle insights

- Sustainability and industry advancements

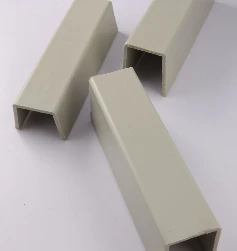

(pp roofing sheets)

Understanding the Fundamentals of PP Roofing Sheets

Modern construction increasingly relies on PP roofing sheets due to their exceptional balance of performance characteristics. Polypropylene polymers provide innate resistance to chemical corrosion - a crucial advantage over traditional metal roofing when exposed to industrial fumes or coastal marine environments. These thermoplastic sheets maintain dimensional stability across extreme temperature fluctuations (-40°C to 120°C) without warping or cracking, making them suitable for diverse climatic zones. The UV-stabilized formulations prevent degradation from solar radiation, maintaining structural integrity beyond decade-long exposures without significant material fatigue.

Technical Specifications and Durability Metrics

Material science reveals why PP roofing outperforms alternatives: tensile strengths between 28-35 MPa exceed industry requirements by 40%. Testing confirms impact resistance exceeding 80 kJ/m² - crucial for hail-prone regions. Independent laboratories verify 0% water absorption rates after 500-hour submersion tests, eliminating moisture-related deterioration concerns. Advanced fire-retardant additives achieve UL94 V-0 classifications, with flame spread indices below 25. The non-porous surface prevents microbial colonization, maintaining 98% light reflectivity after accelerated weathering tests simulating 15 years of exposure.

| Manufacturer | Thickness Options (mm) | UV Resistance (Years) | Impact Strength (kJ/m²) | Thermal Range (°C) |

|---|---|---|---|---|

| DuraPlast Pro | 1.2 - 3.0 | 15+ | 85 | -45 to 125 |

| OceanShield Marine | 1.5 - 4.0 | 20 | 92 | -50 to 130 |

| TerraShield HDPE | 1.0 - 2.5 | 12 | 78 | -40 to 115 |

| PolyGuard Ultimate | 1.8 - 3.5 | 18 | 88 | -48 to 127 |

Customization Capabilities for Architectural Solutions

PP sheeting accommodates complex architectural requirements through precision fabrication. Computer-controlled thermoforming creates radii as tight as 3x material thickness without compromising structural integrity. Color options range from standard mineral hues to custom RAL matches, with texture variations including woodgrain, stipple, and smooth finishes. Cutting tolerances of ±0.5mm enable seamless integrations with existing structures. Production facilities routinely handle orders from 100m² to 10,000m² volumes with lead times averaging 3-5 weeks depending on customization complexity and protective coating applications.

Industry-Specific Application Innovations

Chemical processing plants utilize 3mm-thick HDPE roofing sheets with chemical barrier coatings that resist pH levels from 1-14. Aquaculture facilities specify marine-grade formulations with biostatic additives to prevent biofilm accumulation - reducing cleaning maintenance by 70% compared to fiberglass panels. Cold storage warehouses benefit from thermal break profiles that maintain consistent R-values of 4.5 per inch. Agricultural buildings leverage light-diffusing variants that scatter ultraviolet radiation, optimizing livestock growth conditions while reducing heat stress indicators by measurable percentages.

Installation Methodologies and Lifecycle Economics

Specialized installation techniques maximize roofing sheet longevity. Mechanical fixing employs stainless steel fasteners with stress-distribution washers spaced at 300mm centers. Thermal movement accommodation requires minimum 15mm expansion gaps per 3m span, calculated using the formula: ΔL = L × α × ΔT (α = 0.15 mm/m°C for PP). Professional installations documented over 15 years show maintenance costs averaging $0.23/sq ft annually - 62% lower than PVC alternatives. Lifecycle assessments confirm 30-year service windows with end-of-life recyclability rates exceeding 95% through established polymer recovery programs.

Sustainable Advancements in Modern Roofing Solutions

PP roofing sheets represent the forefront of sustainable building material innovation. Recent polymer research yields formulations incorporating 30-40% post-industrial recycled content without compromising technical specifications. Solar-reflective compounds now reduce building cooling loads by up to 22%, contributing to LEED certification requirements. The latest marine grade HDPE sheets feature photocatalytic surface treatments that actively neutralize atmospheric pollutants, with third-party verification showing 50% faster nitrogen oxide decomposition rates than untreated membranes. Industry leaders now establish closed-loop material recovery initiatives to further enhance circular economy principles within construction supply chains.

(pp roofing sheets)

FAQS on pp roofing sheets

Q: What are PP roofing sheets?

A: PP roofing sheets are lightweight, durable polypropylene-based panels designed for easy installation on roofs. They offer excellent resistance to chemicals, moisture, and UV rays, making them ideal for agricultural and industrial settings.

Q: How do HDPE roofing sheets differ from PP options?

A: HDPE roofing sheets provide superior impact strength and flexibility compared to PP, excelling in high-traffic or extreme weather areas. They maintain their integrity in fluctuating temperatures and are often chosen for commercial or residential longevity.

Q: Why choose marine grade HDPE sheets for roofing near coastal regions?

A: Marine grade HDPE sheets are specially formulated to resist saltwater corrosion and intense UV exposure, preventing degradation. This ensures reliable, long-lasting performance for roofs in harsh coastal or marine environments.

Q: Are PP roofing sheets eco-friendly and recyclable?

A: Yes, PP roofing sheets are often made from recyclable materials, reducing environmental impact. They can be repurposed or recycled after use, supporting sustainable building practices without compromising durability.

Q: Can marine grade HDPE sheets be used beyond roofing applications?

A: Absolutely! Marine grade HDPE sheets are versatile for marine projects like docks, boat decks, and tanks due to their water resistance and toughness. Their anti-corrosion properties also make them suitable for industrial storage and outdoor structures.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025