Nov . 05, 2025 05:15 Back to list

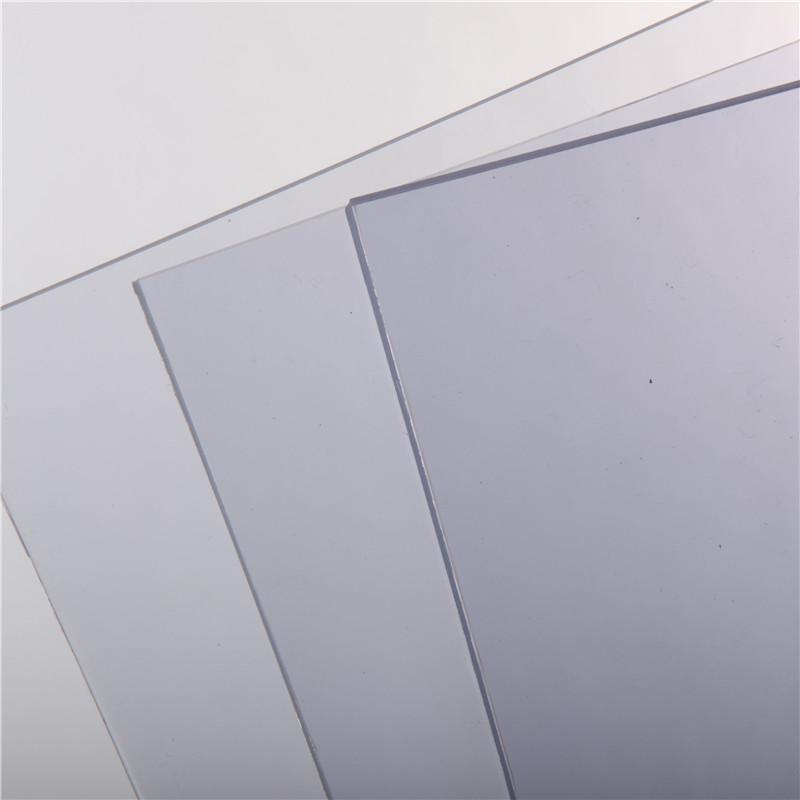

PVC Clear Sheet | High Clarity, Impact Resistant, Custom Cut

PVC Clear Sheet is a key solution in the manufacturing industry, specifically within plastic product industry and Manufacturing of plastic boards, sheets, and films. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Clear Sheet Overview

- Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

PVC Clear Sheet Overview

PVC Clear Sheet is a rigid, transparent sheet extruded from polyvinyl chloride resin and engineered for optical clarity, strength, and processability. In the plastic product industry—especially the Manufacturing of plastic boards, sheets, and films—this material is valued for its balance of clarity, impact resistance, chemical resistance, and ease of fabrication. It can be cut, routed, drilled, bent with heat, glued, and thermoformed, making it a versatile choice for protective panels, displays, packaging components, and machine guards.

Typical supply ranges include thicknesses from sub-millimeter gauges for printing and packaging up to several millimeters for structural covers; common widths are optimized for efficient yield on CNC routing and die cutting. Depending on the application, PVC Clear Sheet can be supplied with high-gloss or matte surface, UV-stabilized or anti-static formulations, and protective masking films to keep surfaces pristine through converting. With a Vicat softening temperature generally around 75–80°C and good dimensional stability, it performs well in low- to mid-temperature forming and fabrication workflows.

Baoding Lida Plastic Industry Co., Ltd provides consistent thickness control and optical uniformity across each sheet, supporting downstream efficiency for OEMs and converters. As a reliable manufacturer serving global B2B customers, the company offers customization on size, color tint, surface finish, and packaging to align with your production and logistics requirements.

Benefits & Use Cases of PVC Clear Sheet in Manufacturing of plastic boards, sheets, and films

Across factories and fabrication shops, PVC Clear Sheet supports a wide spectrum of applications: transparent machine guards and barriers, instrument covers, retail and industrial displays, printed signage and POP components, thermoformed trays and housings, clamshells and box windows, as well as glazing alternatives where weight and impact demands make glass impractical. Its formability at comparatively lower temperatures helps shorten production cycles for vacuum forming and reduces energy consumption during bending and line-scoring operations.

Key advantages include excellent clarity, reliable thickness uniformity, good chemical resistance to cleaners and many industrial agents, and inherent self-extinguishing behavior of PVC (with optional flame-retardant or UV-stabilized formulations). Compared to many clear engineering plastics, PVC Clear Sheet can deliver a compelling cost-to-performance ratio while remaining easy to print, bond, and fabricate using standard shop tools. Options such as anti-static grades, protective masking, and matte/embossed textures broaden application flexibility for converters and OEMs.

Baoding Lida Plastic Industry Co., Ltd leverages proven extrusion know-how to produce stable, high-yield sheet that runs cleanly on CNC routers, lasers (check compatibility), and presses. For project teams, this translates into fewer reworks, smoother print registration, and predictable forming behavior—critical factors when scaling production or meeting tight launch timelines.

Cost, Maintenance & User Experience

Total cost of ownership for PVC Clear Sheet is influenced by resin grade, thickness, surface finish, masking, tolerances, and order quantities. In many programs, it delivers strong ROI by combining competitive material cost with shorter cycle times (thanks to lower forming temperatures), reduced secondary finishing, and lower breakage risk compared with glass. For volume buyers, efficient nesting and minimal thickness variation further reduce scrap and labor, strengthening margins for converters and OEMs.

Maintenance is straightforward: clean with a soft microfiber cloth and a mild soap solution; avoid abrasive pads and aggressive solvents such as ketones or chlorinated cleaners to prevent surface haze or crazing. For high-traffic installations, consider protective films or hard-coat options where available. Users in the plastic product industry value the sheet’s balance of clarity and durability, reporting smooth printing results, stable heat-bending performance, and consistent adhesion with common PVC-compatible cements and tapes. Baoding Lida Plastic Industry Co., Ltd supports repeatable outcomes by providing protective masking, moisture-controlled packaging, and clear handling guidance to maintain optical quality from dock to production floor.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping material choices across the manufacturing of plastic boards, sheets, and films. PVC Clear Sheet can participate in circular strategies through in-plant scrap reclamation and mechanical recycling pathways where infrastructure exists. Many buyers now request heavy-metal-free stabilization systems, low-VOC processing, and documentation aligned with common regulatory frameworks. Formulations can be tailored to support cleaner chemistries, including options designed to align with RoHS- and REACH-oriented requirements where applicable.

Market demand remains resilient in sectors such as industrial safety glazing, retail/POP, packaging, and equipment enclosures—especially where clarity, printability, and flame behavior are important. Baoding Lida Plastic Industry Co., Ltd positions itself as a forward-thinking, eco-conscious supplier by optimizing extrusion efficiency, offering recycled-content options where feasible, and helping customers right-size specifications to reduce material consumption without compromising performance. The result is a more resource-efficient supply chain and a product that aligns with evolving corporate sustainability goals.

Conclusion on PVC Clear Sheet from Baoding Lida Plastic Industry Co., Ltd

For B2B decision makers in the plastic product industry, PVC Clear Sheet offers a reliable blend of clarity, strength, formability, and value. It supports high-yield converting, clean printing, and durable end-use performance across machine guards, displays, packaging, and more. Baoding Lida Plastic Industry Co., Ltd stands out for consistent quality, customization options, and responsive technical support that help teams launch faster and run leaner. Ready to specify or quote? Contact us: email: lidaplastic@ldsy.cn. Visit our website: https://www.lidaplastic.com.

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025