Aug . 27, 2025 04:40 Back to list

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

Introduction to HDPE Natural Sheet and Industry Trends

In the realm of advanced polymer materials, HDPE Natural Sheet stands out as a highly versatile and indispensable component across numerous industrial applications. High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from the monomer ethylene, renowned for its high strength-to-density ratio. The "natural" designation refers to its unpigmented, translucent white appearance, indicating a pure, virgin material often preferred for applications where color stability, non-toxicity, or food contact compliance is critical.

The global demand for high-performance plastics continues to surge, driven by expanding industrialization, technological advancements, and an increasing focus on sustainable and durable materials. HDPE, in particular, benefits from its excellent chemical resistance, high impact strength, low moisture absorption, and good tensile strength. Market trends indicate a strong trajectory for HDPE sheets, particularly in sectors requiring robust, lightweight, and corrosion-resistant solutions.

Current industry trends emphasize several key areas influencing the adoption of materials like HDPE. Firstly, the drive towards greater efficiency and energy conservation in manufacturing processes pushes for materials that offer extended service life and reduced maintenance. Secondly, the increasing stringent regulatory environment, especially concerning environmental and health standards (e.g., FDA compliance for food contact, REACH for chemical safety), favors inert and non-toxic materials. Lastly, the push for circular economy principles means materials that are recyclable and have a lower environmental footprint are increasingly preferred, an area where HDPE excels due to its recyclability code #2.

These factors collectively position HDPE Natural Sheet as a material of choice for engineers and procurement specialists seeking reliability, performance, and compliance in their operational infrastructure.

Understanding HDPE Natural Sheet: The Manufacturing Process

The production of HDPE Natural Sheet involves a sophisticated and controlled process to ensure consistent quality and performance. The raw material, high-density polyethylene resin, typically arrives in pellet form. This virgin resin is critical for achieving the "natural" sheet's desired properties and purity.

Process Flow Overview:

- Material Preparation: HDPE pellets are carefully selected, ensuring they meet specific melt flow index (MFI) and density requirements. The material may undergo pre-drying to remove any residual moisture, preventing defects during extrusion.

- Extrusion: The core of sheet production. Pellets are fed into an extruder, where they are melted by heat and shear forces from a rotating screw. The molten polymer is then pushed through a flat die, forming a continuous sheet. This process, unlike casting or forging, creates a uniform, monolithic sheet with consistent thickness.

- Calendering/Forming: Immediately after exiting the die, the hot sheet passes through a series of polished, cooled rollers (calender stack). These rollers precisely gauge the thickness, flatten the sheet, and impart a smooth surface finish while rapidly cooling the material to solidify its dimensions.

- Cooling and Trimming: The solidified sheet continues along a cooling conveyor, ensuring complete stabilization. Edges are then trimmed to exact widths using automated cutting tools, preparing it for final sizing.

- Cutting and Finishing: The continuous sheet is cut into specified lengths. Depending on customer requirements, secondary processes like protective film application, routing (similar to CNC machining for specific shapes), or surface treatments might be applied.

- Quality Control and Testing: Throughout the process, stringent quality checks are performed. This includes density measurements (ASTM D1505), tensile strength (ASTM D638), impact resistance (ASTM D256), and dimensional accuracy. Compliance with standards like ISO 9001 for quality management and industry-specific standards (e.g., FDA for food contact, NSF for potable water) is paramount.

The service life of a well-manufactured HDPE Natural Sheet can extend decades, especially in benign environments. In demanding applications, its resilience against abrasion, chemical exposure, and UV degradation (when UV-stabilized grades are used, though "natural" typically implies less UV resistance than black HDPE) ensures longevity. Target industries include petrochemical (tank linings, pipe supports), metallurgy (wear plates, chute liners), and water supply & drainage (potable water tanks, pipe systems) due to its exceptional corrosion resistance and non-leaching properties. The material's inherent low friction also contributes to energy savings in material handling systems.

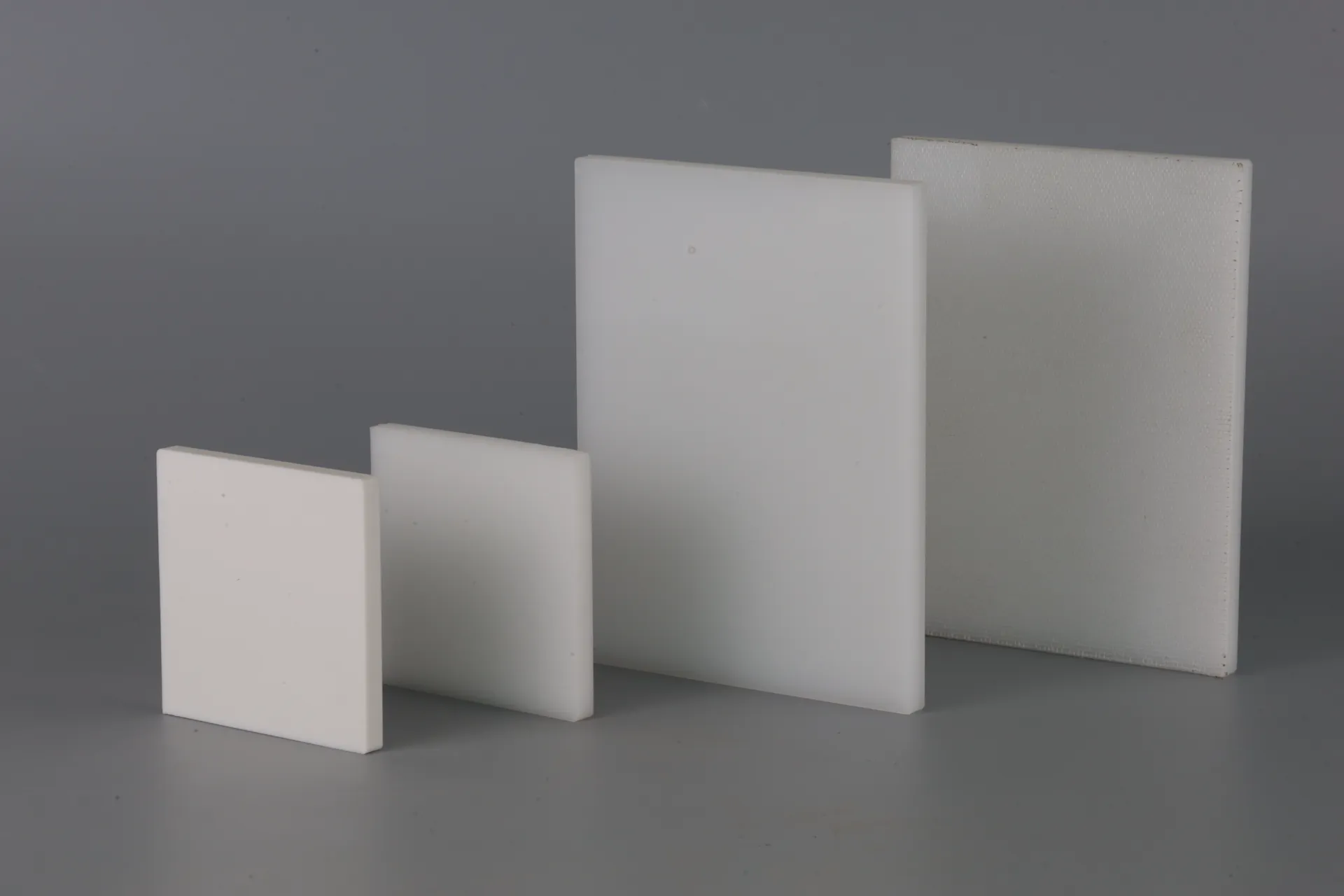

Figure 1: High-Density Polyethylene (HDPE) sheet during manufacturing process.

Technical Specifications and Performance Parameters

The robust performance profile of HDPE Natural Sheet is underpinned by a specific set of technical specifications that make it suitable for a wide range of industrial applications. Understanding these parameters is crucial for engineers designing systems where material integrity and longevity are paramount.

Typical HDPE Natural Sheet Specifications:

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Density | ASTM D1505 / ISO 1183 | g/cm³ | 0.95 - 0.96 |

| Tensile Strength at Yield | ASTM D638 / ISO 527 | MPa | 24 - 31 |

| Elongation at Break | ASTM D638 / ISO 527 | % | >500 |

| Flexural Modulus | ASTM D790 / ISO 178 | MPa | 900 - 1300 |

| Hardness (Shore D) | ASTM D2240 / ISO 868 | - | 60 - 70 |

| Izod Impact Strength (Notched) | ASTM D256 / ISO 180 | J/m | >100 (No Break) |

| Melting Point | ASTM D3418 / ISO 11357 | °C | 130 - 135 |

| Continuous Service Temperature | - | °C | -50 to 80 |

| Coefficient of Linear Thermal Expansion | ASTM D696 / ISO 11359 | 10⁻⁶/K | 110 - 200 |

| Water Absorption (24h) | ASTM D570 / ISO 62 | % | <0.01 |

These parameters illustrate why HDPE Natural Sheet is preferred in demanding industrial environments where resistance to chemicals, impact, and fatigue is crucial. Its low water absorption ensures dimensional stability in humid or submerged conditions, while its broad service temperature range allows for applications in varying climates.

Key Technical Advantages

The specific material properties of HDPE Natural Sheet translate into a host of technical advantages that are highly valued in B2B applications, offering significant operational benefits and cost savings over the material's lifecycle.

- Exceptional Chemical Resistance: HDPE is highly resistant to a wide range of acids, bases, and organic solvents. This makes it ideal for chemical storage tank linings, laboratory countertops, and processing equipment where exposure to corrosive substances is common, ensuring integrity and preventing degradation.

- Superior Wear and Abrasion Resistance: Its molecular structure provides excellent resistance to abrasion, making it perfect for applications involving friction or impact. This includes chute liners, wear strips, and conveyor components, significantly extending equipment lifespan and reducing replacement costs.

- Low Coefficient of Friction: HDPE's inherently slick surface minimizes friction between moving parts or between the sheet and conveyed materials. This property is crucial in material handling, reducing energy consumption in machinery and preventing material build-up in hoppers and silos.

- High Impact Strength: Even at low temperatures, HDPE maintains considerable toughness and resistance to impact. This characteristic makes it resilient in harsh industrial environments where impact loads are possible, such as in processing lines or protective barriers.

- Excellent Machinability and Weldability: HDPE sheets can be easily cut, routed, drilled, and fabricated into complex shapes using standard tooling. Furthermore, they are readily weldable using hot air or extrusion welding techniques, allowing for the creation of seamless, leak-proof structures like tanks and ductwork.

- Food Grade and Non-Toxic Compliance: Natural HDPE sheets, especially those made from virgin resin, often comply with FDA and NSF standards for food contact and potable water applications. This makes them indispensable in food processing, pharmaceutical, and water treatment industries where hygiene and non-contamination are critical.

- Lightweight and Cost-Effective: Compared to metals or other engineered plastics, HDPE offers a high strength-to-weight ratio, contributing to lighter structures and reduced transportation costs. Its long service life and minimal maintenance requirements further enhance its cost-effectiveness over time.

These advantages underscore why HDPE Natural Sheet is a preferred material for engineers and designers seeking reliable, high-performance, and economically viable solutions for diverse industrial challenges.

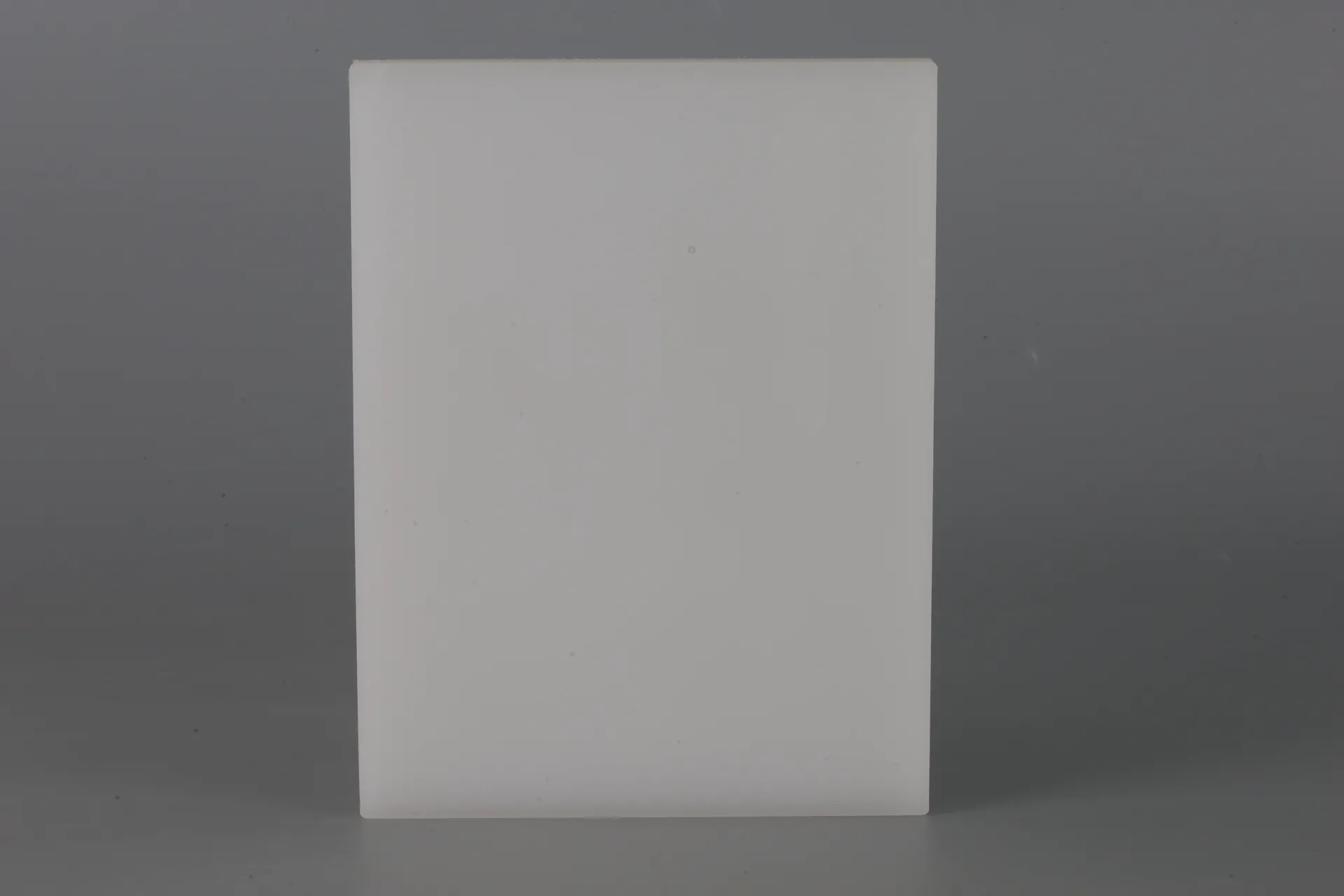

Figure 2: Close-up view of HDPE sheet showcasing its natural finish and structural integrity.

Application Scenarios Across Industries

The versatility and robust properties of HDPE Natural Sheet enable its use in an expansive array of application scenarios across critical industrial sectors. Its performance characteristics address specific operational demands, contributing to enhanced efficiency, safety, and longevity of systems.

- Food Processing and Packaging: Due to its non-toxic, FDA-compliant nature and ease of cleaning, HDPE Natural Sheet is extensively used for cutting boards, conveyor wear strips, splash guards, and tank linings in food and beverage processing plants. Its low moisture absorption prevents bacterial growth, crucial for hygiene.

- Chemical Processing and Storage: Its exceptional chemical resistance makes it ideal for fabricating tank liners, secondary containment systems, fume hoods, and pipe components for handling aggressive chemicals. This provides a cost-effective alternative to expensive alloys.

- Water Treatment and Utilities: HDPE is widely adopted for potable water storage tanks, filtration system components, and wastewater treatment equipment. Its inertness ensures no leaching of harmful substances into water, complying with NSF standards.

- Material Handling and Bulk Storage: For applications involving abrasive materials like grain, coal, sand, or gravel, HDPE sheets are used as chute linings, hopper liners, and conveyor side guides. The low friction surface prevents clogging and facilitates smooth material flow, leading to energy savings and reduced downtime.

- Marine and Outdoor Applications: While natural HDPE has less inherent UV resistance than black HDPE, specialized UV-stabilized natural grades can be used for marine components, dock bumpers, and outdoor signage backings where lightweight and water resistance are key.

- Automotive and Transportation: Used in various non-structural components like cargo liners, sound insulation panels, and protective barriers due to its impact strength and lightweight properties.

- Medical and Pharmaceutical: The material's purity and chemical resistance lend it to components in medical devices, sterile environment surfaces, and pharmaceutical processing equipment.

These diverse applications underscore the adaptability of HDPE Natural Sheet as a fundamental engineering material, offering reliable solutions for a broad spectrum of industrial challenges.

Customized Solutions and Fabrication

Beyond standard sheet formats, the true value of HDPE Natural Sheet often lies in its capacity for customization and precision fabrication. Manufacturers and suppliers frequently offer a range of services to tailor HDPE sheets to specific project requirements, ensuring optimal fit and performance.

Tailoring HDPE for Specific Needs:

- Custom Sizing and Thicknesses: While standard sizes exist, vendors can typically provide HDPE sheets cut to exact dimensions, minimizing waste and reducing fabrication time for the end-user. Thicknesses can range from very thin gauges for flexible applications to thick plates for heavy-duty structural components.

- CNC Machining and Routing: Utilizing Computer Numerical Control (CNC) technology, HDPE sheets can be precisely machined to create complex geometries, intricate patterns, holes, and edge profiles. This includes custom wear strips, intricate gaskets, sprockets, and component parts with tight tolerances.

- Welding and Forming: HDPE is thermoformable and can be welded to create large, seamless structures such as tanks, liners for chemical baths, and ducting systems. Hot air welding, extrusion welding, and butt fusion techniques ensure strong, leak-proof joints critical for fluid handling and containment.

- Surface Finishes: While natural HDPE typically has a smooth finish, it can be provided with various textures, such as stippled or cross-hatched, to enhance grip, reduce slip, or improve aesthetics for specific applications.

- Additives and Blends: For specialized applications, HDPE can be formulated with additives. While the "natural" sheet implies minimal additives, UV stabilizers can be incorporated for outdoor use, antistatic agents for environments with static discharge concerns, or impact modifiers for extreme toughness requirements. These modifications are often done at the resin level before extrusion.

Engaging with a vendor that offers comprehensive fabrication services ensures that the HDPE Natural Sheet precisely meets the technical and functional demands of your project, often resulting in superior performance and reduced overall project costs compared to in-house efforts or less specialized suppliers.

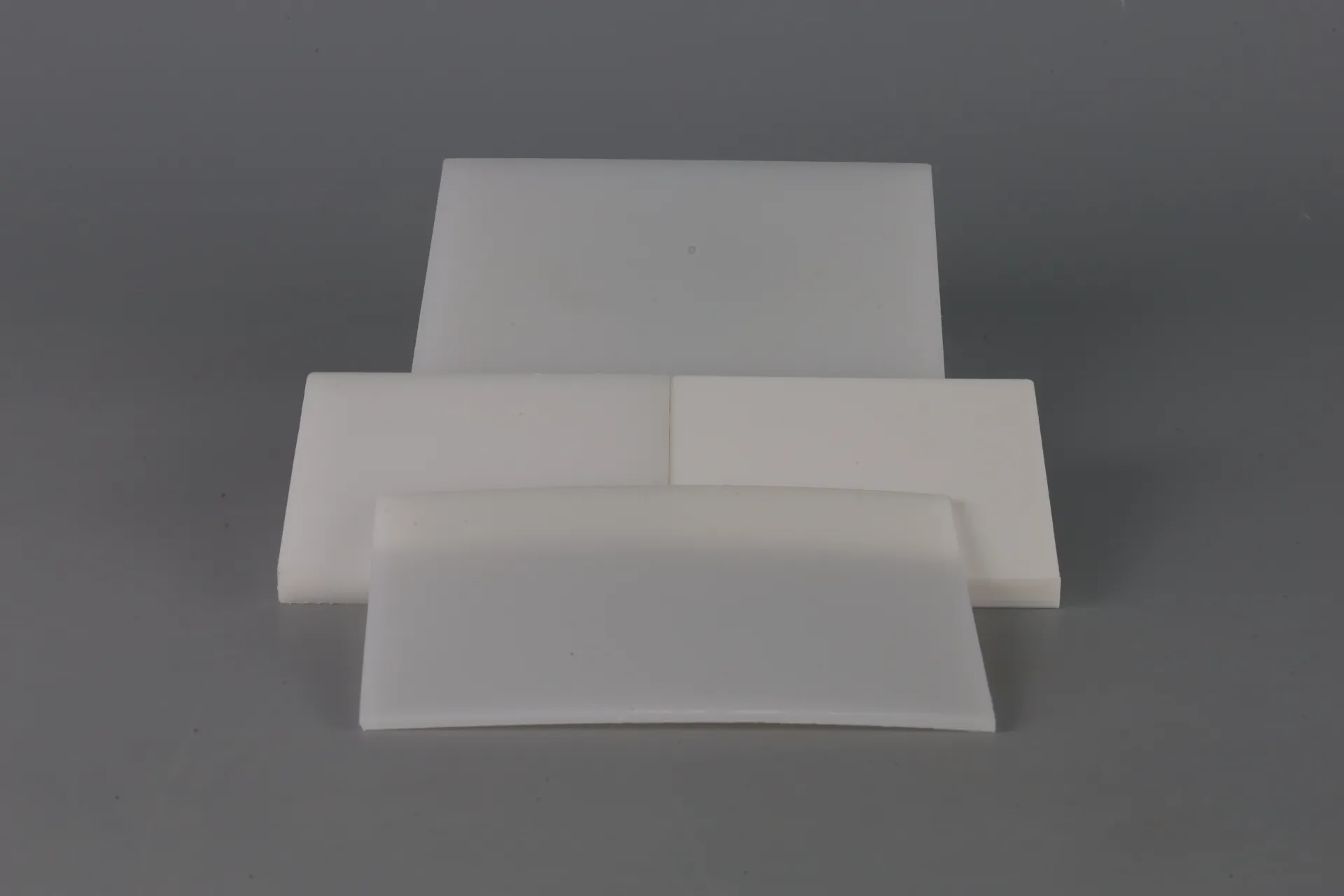

Figure 3: Samples of custom-machined HDPE components.

Vendor Comparison and Selection Criteria

Selecting the right supplier for HDPE Natural Sheet is as crucial as understanding the material itself. A strategic vendor partnership ensures consistent quality, competitive pricing, and reliable support. This section outlines key criteria for comparing vendors to make an informed procurement decision.

Key Vendor Evaluation Factors:

- Material Quality and Certifications: Verify that the vendor's HDPE sheets meet international standards (e.g., ISO, ASTM, DIN) and possess relevant industry certifications (e.g., FDA compliance for food-grade, NSF for potable water, REACH for environmental safety). Ask for Certificates of Conformance (CoCs) for specific batches.

- Manufacturing Capabilities: Assess the vendor's extrusion and fabrication capabilities. Can they produce the required sheet dimensions, thicknesses, and finishes? Do they offer advanced services like CNC machining, welding, or thermoforming for custom parts?

- Technical Expertise and Support: A reputable vendor should have a team of technical specialists capable of providing detailed material data, application advice, and troubleshooting support. This is invaluable for complex projects or when optimizing material use.

- Lead Times and Logistics: Evaluate the vendor's ability to meet your project timelines. Inquire about typical lead times for standard and custom orders, shipping options, and inventory management capabilities to ensure a reliable supply chain.

- Customer Service and Reputation: Look for vendors with a strong track record of customer satisfaction, responsive communication, and problem-solving. Review customer testimonials, case studies, and industry references.

- Pricing and Value Proposition: While cost is a factor, it should not be the sole determinant. Compare overall value, including material quality, service, technical support, and the potential for long-term cost savings through material performance and durability.

Comparative Analysis Example: Standard vs. Premium HDPE Sheet

| Feature | Standard Grade HDPE | Premium Grade HDPE (e.g., Virgin, High Molecular Weight) |

|---|---|---|

| Raw Material | Often mixed with regrind or lower quality virgin resin | 100% Virgin High-Molecular-Weight Resin |

| Density (g/cm³) | 0.94 - 0.95 | 0.95 - 0.965 |

| Tensile Strength (MPa) | 20 - 25 | 28 - 35 |

| Wear Resistance | Good | Excellent, significantly longer lifespan |

| Impact Strength | Good at ambient temperatures | Exceptional, even at low temperatures |

| Chemical Purity | Acceptable for general industrial use | High purity, often FDA/NSF compliant |

| Typical Applications | General fabrication, non-critical linings | Food processing, chemical tanks, critical wear applications |

By carefully evaluating these factors and understanding the nuances between different grades, procurement professionals can ensure they source the most appropriate and cost-effective HDPE Natural Sheet for their specific industrial needs.

Real-World Application Case Studies

To further illustrate the practical benefits and reliability of HDPE Natural Sheet, examining real-world application case studies provides tangible evidence of its value in diverse industrial settings.

Case Study 1: Chute Liners in a Grain Handling Facility

A large agricultural cooperative experienced significant downtime and material flow issues in their grain elevators due to wear and friction in their steel transfer chutes. Grains, particularly corn and wheat, are abrasive and created substantial friction, leading to blockages and premature wear of metal surfaces.

- Challenge: Reduce abrasion, improve material flow, and extend the lifespan of grain chutes.

- Solution: They implemented custom-fabricated linings of 15mm thick HDPE Natural Sheet within their existing steel chutes. The sheets were precisely cut and securely fastened to the interior surfaces.

- Results: The low coefficient of friction of HDPE drastically reduced material hang-ups and blockages, leading to a 20% increase in throughput capacity. The superior abrasion resistance extended the liner lifespan by over 300% compared to unlined steel, significantly reducing maintenance costs and downtime.

Case Study 2: Chemical Storage Tank Linings for Pharmaceutical Production

A pharmaceutical manufacturing plant needed reliable internal linings for new chemical storage tanks containing various acids and alkalis used in drug synthesis. Stainless steel tanks were prohibitively expensive and susceptible to specific corrosive agents over time.

- Challenge: Provide a highly chemical-resistant, non-leaching, and cost-effective lining solution for critical chemical storage.

- Solution: The company opted for 10mm thick HDPE Natural Sheet, chosen for its broad chemical resistance profile and compliance with pharmaceutical purity standards. The sheets were expertly hot-air welded to create a seamless, liquid-tight lining for the concrete and steel tanks.

- Results: The HDPE lining successfully contained the aggressive chemicals without any signs of degradation or leaching into the stored substances. This provided a secure, long-term storage solution at a fraction of the cost of exotic alloy tanks, with minimal maintenance requirements. Audits confirmed the material's non-contaminating properties.

Case Study 3: Potable Water Reservoir Covers

A municipal water utility needed durable, weather-resistant, and chemically inert covers for several potable water reservoirs to prevent contamination from environmental debris and airborne pollutants.

- Challenge: Protect large open-air potable water reservoirs from contamination while ensuring long-term material integrity and safety for drinking water.

- Solution: Large sheets of UV-stabilized HDPE Natural Sheet (specifically formulated for outdoor exposure) were used to construct floating and fixed covers. The sheets were welded together to form expansive, watertight membranes.

- Results: The HDPE covers effectively prevented contamination and evaporation. The material's compliance with NSF standards for potable water ensured safety, while its robust nature provided excellent resistance to environmental factors like sunlight and temperature fluctuations. The low maintenance and extended service life offered significant operational savings for the utility.

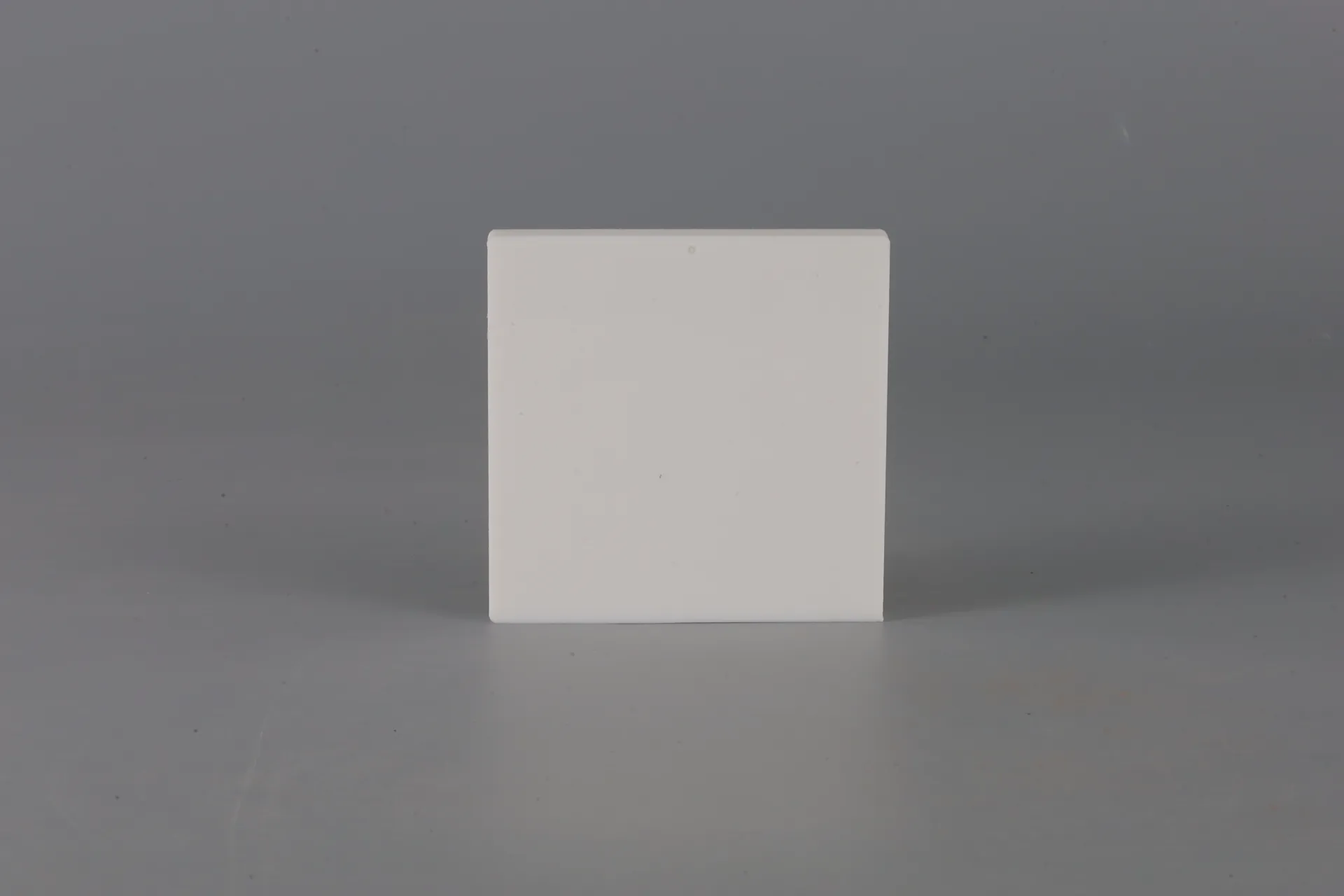

Figure 4: HDPE sheets used in a fabrication environment for custom components.

Frequently Asked Questions (FAQ)

Addressing common inquiries about HDPE Natural Sheet helps clarify its properties and applications for B2B decision-makers and engineers.

- Q1: What does "Natural" in HDPE Natural Sheet signify?

- A1: "Natural" refers to the unpigmented, virgin form of High-Density Polyethylene. It has a translucent white appearance and is typically used when color additives are undesirable, particularly in food contact or pharmaceutical applications, emphasizing its purity.

- Q2: Is HDPE Natural Sheet suitable for outdoor applications?

- A2: Standard natural HDPE has limited UV resistance and can degrade over long periods of direct sunlight exposure. For outdoor applications, it is recommended to use UV-stabilized grades of HDPE (often black or specially formulated natural sheets with UV additives) to ensure longevity and prevent material degradation.

- Q3: Can HDPE Natural Sheet be used in food processing environments?

- A3: Yes, virgin HDPE Natural Sheet is widely accepted for food processing applications, often complying with FDA and NSF standards. Its non-toxic nature, low moisture absorption, and ease of cleaning make it an excellent choice for cutting boards, conveyor components, and tank liners in the food and beverage industry.

- Q4: How does HDPE compare to UHMW-PE?

- A4: Both are polyethylenes, but Ultra-High Molecular Weight Polyethylene (UHMW-PE) has a significantly higher molecular weight. UHMW-PE offers superior abrasion resistance and impact strength, especially in extreme wear conditions, but is generally more expensive and harder to process than standard HDPE. HDPE offers a strong balance of properties for most industrial applications where UHMW-PE's extreme characteristics aren't strictly necessary.

- Q5: What are the typical lead times for HDPE Natural Sheet orders?

- A5: Lead times can vary depending on quantity, customization requirements, and current production schedules. For standard sheets, typical lead times might range from 1-2 weeks. For custom-machined parts or large volume orders, it could be 3-6 weeks. We recommend contacting our sales team for precise lead time estimates based on your specific order.

- Q6: What is the warranty for HDPE Natural Sheet products?

- A6: Our HDPE Natural Sheet products typically come with a standard manufacturer's warranty against defects in material and workmanship. The specific terms and duration of the warranty may vary by product and application, and detailed warranty information is available upon request or with your purchase agreement.

Lead Time, Warranty, and Customer Support

At Lida Plastic, we understand that reliable logistics, clear warranty terms, and accessible customer support are paramount for our B2B clients. Our commitment extends beyond providing high-quality HDPE Natural Sheet to ensuring a seamless and supportive procurement experience.

Lead Time & Fulfillment:

- Standard Orders: For commonly stocked dimensions and thicknesses of HDPE Natural Sheet, we typically fulfill orders within 5-10 business days.

- Custom & Fabricated Orders: Projects requiring custom dimensions, CNC machining, welding, or large volumes will have lead times quoted on a case-by-case basis, generally ranging from 2-4 weeks, depending on complexity and current production load. Our sales team provides transparent and accurate estimates at the time of inquiry.

- Expedited Options: We offer expedited manufacturing and shipping solutions for urgent requirements. Please discuss your critical deadlines with our team to explore feasibility and associated costs.

Warranty Commitments:

All HDPE Natural Sheet products supplied by Lida Plastic are covered by a limited warranty against defects in materials and manufacturing. This warranty typically extends for one year from the date of purchase, ensuring that our products meet the specified technical parameters and are free from latent defects under normal use and service conditions. Specific warranty details, including exclusions and remedies, are provided with each quotation and order confirmation, aligning with industry standards and our commitment to quality assurance.

Dedicated Customer Support:

Our commitment to client success is supported by a robust customer service framework. Our team of experienced technical and sales professionals is available to assist you with:

- Product selection and material suitability advice.

- Detailed technical specifications and data sheets.

- Quotation requests and order status updates.

- Post-sales support, including troubleshooting and warranty claims.

- Custom fabrication inquiries and project consultations.

We pride ourselves on responsive communication and building lasting partnerships through reliable product delivery and unparalleled support. Contact us via phone, email, or our website for any assistance.

Certifications and Authoritative References

Authoritativeness and trustworthiness are cornerstones of our operations. Lida Plastic adheres to stringent quality control and manufacturing standards, ensuring that our HDPE Natural Sheet products meet or exceed international industry benchmarks. Our commitment is evidenced by our certifications and adherence to authoritative references.

Key Certifications and Standards Adherence:

- ISO 9001: Our manufacturing processes are certified under ISO 9001, demonstrating a robust quality management system that ensures consistent product quality and customer satisfaction.

- FDA Compliance: Many of our HDPE Natural Sheet grades are compliant with FDA regulations for direct food contact (e.g., FDA 21 CFR 177.1520), making them safe for use in food processing, packaging, and medical applications.

- NSF/ANSI Standard 61: For potable water applications, specific grades of HDPE are tested and certified to NSF/ANSI Standard 61, ensuring they do not leach contaminants into drinking water.

- REACH and RoHS Compliance: We ensure our products comply with environmental regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances), reflecting our commitment to environmental responsibility.

- ASTM International Standards: Our material properties are rigorously tested according to ASTM standards (e.g., ASTM D1505 for density, ASTM D638 for tensile strength), providing verifiable performance data.

Partner Clients and Industry Standing:

With over two decades of experience in the polymer industry, Lida Plastic has established itself as a trusted supplier to a global clientele. Our long-standing relationships with leading companies in petrochemical, food & beverage, water treatment, and material handling sectors testify to our reliability and product quality. We routinely supply materials for critical infrastructure projects and collaborate with engineering firms to develop specialized solutions.

Our dedication to quality, consistent performance, and adherence to global standards reinforces our position as an authoritative and trustworthy source for high-performance plastic materials, including premium HDPE Natural Sheet.

Figure 5: Quality assurance inspection for HDPE sheet.

Conclusion

HDPE Natural Sheet represents a highly effective and versatile solution for a multitude of industrial challenges. Its combination of outstanding chemical resistance, high impact strength, low friction, and excellent machinability positions it as a preferred material in sectors ranging from food processing to heavy industry. By adhering to rigorous manufacturing standards, offering comprehensive customization options, and providing dedicated technical support, Lida Plastic ensures that clients receive not just a product, but a reliable and high-performance solution tailored to their specific operational demands. The strategic selection of this advanced polymer material leads to enhanced operational efficiency, reduced maintenance, and a superior return on investment over its extensive service life.

Citations

- ASTM International. "D638 - Standard Test Method for Tensile Properties of Plastics." ASTM.org.

- Food and Drug Administration. "21 CFR 177.1520 - Olefin Polymers." FDA.gov.

- International Organization for Standardization. "ISO 9001: Quality management systems – Requirements." ISO.org.

- NSF International. "NSF/ANSI Standard 61: Drinking Water System Components – Health Effects." NSF.org.

- The Society of Plastics Industry (SPI). "Plastics Engineering Handbook." 5th Edition, Springer, 2018.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025