Oct . 06, 2025 10:50 Back to list

PP Fire Retardant Sheet: UL94 V-0, Halogen-Free—Why Buy?

PP Fire Retardant Sheet: What Engineers Are Actually Buying in 2025

If you’re evaluating a PP fire retardant sheet for enclosures, chemical tanks, or rail interiors, you’re not alone. Demand’s rising fast as OEMs move to halogen-free, RoHS-compliant materials that still pass tough flame tests. I’ve spent the past year talking to procurement teams and visiting factories—one in Baoding, Hebei, actually—so here’s the straight, field-tested view.

Why this material is having a moment

The short version: engineers want lower smoke, stable performance, and predictable supply. PP fire retardant sheet checks the boxes—good chemical resistance, easy to fabricate, and flame behavior that can meet UL 94 targets at practical thicknesses. Many customers say the machining feels cleaner than FR-ABS, and cost is friendlier than many FR-PC blends.

Core specifications (real-world picks)

| Material | PP homopolymer + halogen-free FR package |

| Thickness | 2–30 mm (cut-to-size available) |

| Standard sizes | 1220×2440 mm; 1000×2000 mm; 1500×3000 mm |

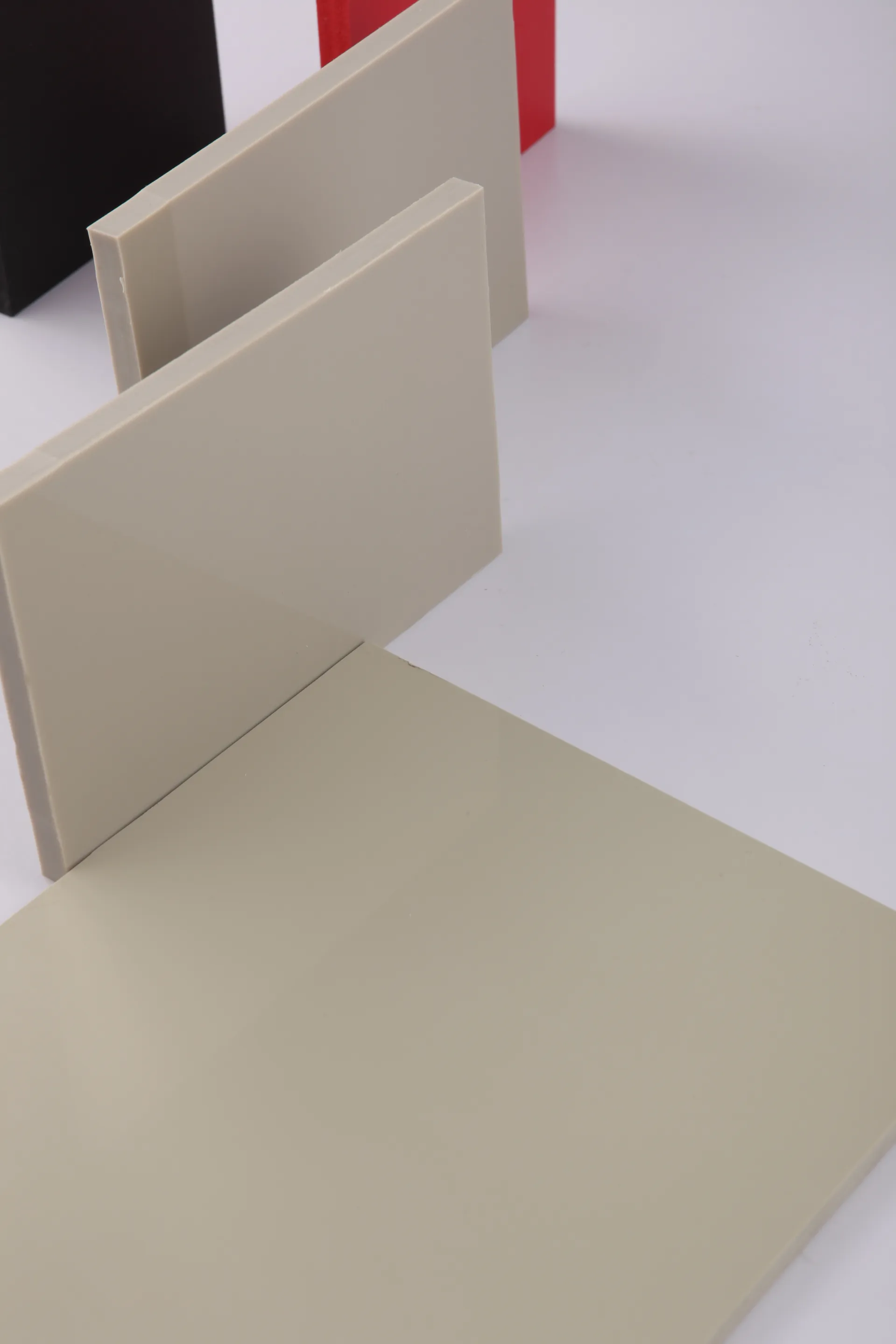

| Surface / Colors | Glossy or embossed; Natural, Grey (RAL7032), Black, custom |

| Flammability | Target UL 94 V-0 at ≥3.0 mm; ≈V-2 around 1.5–2.0 mm (verify per batch) |

| LOI (ASTM D2863) | ≈28–32% (typical for halogen-free FR PP) |

| Density | ≈0.98–1.05 g/cm³ |

| HDT (0.45 MPa) | ≈85–100°C (additive-dependent) |

Manufacturing flow and quality gates

- Materials: PP resin, synergistic mineral FR package, UV stabilizers (option).

- Compounding: Twin-screw extrusion with precise dosing; pelletizing for consistency.

- Sheet extrusion: Flat-die extrusion, thickness control, calibration/cooling, optional emboss.

- Annealing: Reduces internal stress; improves machinability—small detail, big win.

- Testing: UL 94 vertical burn; LOI; IEC 60695 glow-wire (selected grades); tensile/impact; dimensional tolerance.

- Service life: Indoors 8–10 years; outdoors 3–5 years with UV grade (real-world use may vary).

Where it’s being used

Electrical and telecom enclosures, battery pack partitions, cleanroom fixtures, HVAC housings, chemical process tanks and fume scrubbers, rail and bus interior panels. In fact, a metro operator in East Asia swapped phenolic panels for PP fire retardant sheet, cut weight by ≈18%, and simplified maintenance—feedback was “quieter ride, fewer chips.”

Vendor snapshot (what buyers compare)

| Vendor | Certs & Data | Customization | Lead Time | Notes |

|---|---|---|---|---|

| Lida Plastic (Baoding, Hebei) | ISO 9001; UL 94 test reports; RoHS/REACH | Cut-to-size; color match; embossed/glossy; 2–30 mm | ≈7–15 days (stock colors) | Consistent thickness; friendly MOQs |

| Importer A | Basic COA; limited UL detail | Limited sizes; few colors | ≈3–6 weeks | Pricey freight; okay for small runs |

| Local Fabricator B | Shop tests; no UL file | Excellent machining; limited FR grades | ≈5–10 days | Great for prototypes, watch flame rating |

Buying checklist (learned the hard way)

- Ask for recent UL 94 test data at your exact thickness.

- Confirm LOI and any glow-wire ratings (IEC 60695) for electrical cabinets.

- Specify surface (glossy vs. embossed) to hide scuffs in public areas.

- For outdoors, request UV-stabilized PP fire retardant sheet.

- Check thickness tolerance and flatness for CNC routing—saves headaches.

Supplier note: Lida Plastic, No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250. They offer cut-to-size, standard panels (1220×2440; 1000×2000; 1500×3000), and custom colors including RAL7032.

Standards and references

- UL 94 – Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

- ASTM D2863 – Standard Test Method for Measuring the Minimum Oxygen Concentration (LOI).

- IEC 60695-11-10 – Fire hazard testing: Test flames—50 W and 500 W flame tests.

- IEC 60695-2-12/13 – Glow-wire ignition and flammability indices (GWIT/GWFI) for insulating materials.

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025

-

Durable and Efficient HDPE Sprinkler Pipe Fittings for Global Water Systems

NewsNov.18,2025