Oct . 12, 2025 13:25 Back to list

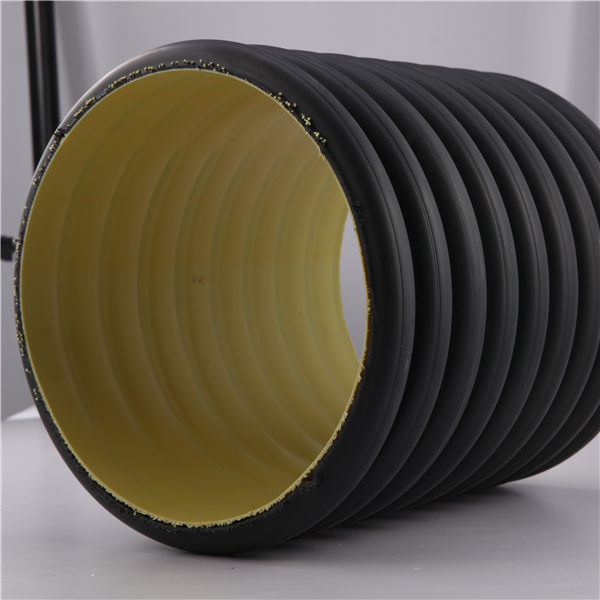

HDPE Double Wall Corrugated Pipe: Lightweight, Watertight

If you’ve been speccing municipal drainage lately, you’ve probably heard the buzz around HDPE double wall corrugated pipe. To be honest, it’s not just hype. The combo of a smooth bore and a stiff, trapezoidal corrugated outer layer is quietly replacing a lot of legacy concrete and PVC in tough ground conditions.

Industry trend check: cities want faster installs, lower lifecycle cost, and resilience against ground movement. Structured-wall HDPE ticks those boxes. In fact, ring-stiffness-graded products (SN4–SN16) are now routinely specified under ISO/EN norms, and—surprisingly to some skeptics—are holding up very well in soft subgrades and high groundwater zones.

How it’s made (quick but technical)

The pipe uses high-density polyethylene resin (usually PE100) blended with carbon black and UV stabilizers. Two extruders co-extrude: inner layer smooth, outer layer vacuum-formed into a trapezoidal corrugation, leaving a hollow ribbed structure between walls. Sockets are formed inline; EPDM gaskets (EN 681-1) are fitted after cooling. Typical QA includes:

- Ring stiffness per ISO 9969 / EN 13476

- Watertightness (air/water) per ISO 13259

- Impact resistance per ISO 3127

- MFI (ISO 1133), density (ISO 1183), OIT (ISO 11357-6)

Service life? With proper embedment and UV-protected storage, ≈50 years underground is a conservative baseline; many customers say their lines look “as-installed” after a decade of CCTV surveys.

Product snapshot

| Spec | Typical Value (≈/range) |

|---|---|

| Nominal diameters | DN110–DN1200 (custom larger on request) |

| Ring stiffness classes | SN4 / SN8 / SN12.5 / SN16 (kN/m²) |

| Inner roughness (Manning n) | ≈0.010–0.011 (real-world use may vary) |

| Joint | Socket + rubber ring (EN 681-1), watertightness per ISO 13259 |

| Chem. resistance | pH ~1–14 (intermittent), common salts/acids/alkalis |

| Standard lengths | 6 m typical; cut-to-length available |

Where it’s used: municipal sewage and stormwater, under-road culverts, industrial outfalls, irrigation, landfill leachate lines, and (increasingly) cable ducting. The HDPE double wall corrugated pipe handles settlement thanks to high impact strength and flexible bell-spigot joints.

Real test data (shop-floor notes)

- SN8 DN400 ring stiffness: ≥8.5 kN/m² (ISO 9969, lab avg; sample lot)

- Air test at 0.5 bar: pass, no bubbles at 15 min (ISO 13259)

- Impact at 0 °C: no crack in 10/10 samples (ISO 3127)

Vendor comparison (quick glance)

| Vendor | Certs/Standards | Customization | Lead time |

|---|---|---|---|

| Lida Plastic (Hebei, CN) | ISO 9001; EN 13476/ISO 21138 alignment; GB/T 19472.1 | DN110–1200, color stripe, SN4–SN16, EPDM/NBR gaskets | ≈10–20 days (seasonal) |

| Vendor A | ISO 9001; AASHTO M294 (partial) | Limited SN classes | ≈20–30 days |

| Vendor B | ASTM F2306; local compliance only | Few molds above DN800 | ≈25–35 days |

Customization and logistics

From No.316 Pingan West Street, Shunping County, Baoding, Hebei, the plant ships bundles with end caps and barcode traceability. Options include colored inner wall (blue/white for CCTV visibility), co-ex resin grades, extra UV package for desert storage, and special gaskets for hydrocarbons. For tricky geology, ask for higher SN with thicker corrugation ribs—engineers like that margin.

Case notes

- Coastal storm drain retrofit (DN600–800): install rate improved ~35% vs. RC pipe; joints stayed tight through two monsoon seasons, according to the contractor.

- Industrial estate sewer (DN400 SN12.5): CCTV at year 5 showed minimal abrasion; operators liked the low headloss. I guess smooth bores do pay off.

Compliance touchpoints: EN 13476 / ISO 21138 families for structured-wall plastics, GB/T 19472.1-2019 in China, ASTM F2306 and AASHTO M294 for comparable North American corrugated HDPE. The HDPE double wall corrugated pipe is squarely in that ecosystem.

Citations

- ISO 21138 (Structured-wall pipes and fittings for drainage and sewerage).

- EN 13476 (Plastics piping systems for non-pressure underground drainage and sewerage).

- ISO 9969 (Thermoplastics pipes – Determination of ring stiffness).

- ISO 13259 (Elastomeric-sealed thermoplastic piping – Infiltration/exfiltration tests).

- GB/T 19472.1-2019 (Buried polyethylene structured-wall pipes – Part 1).

- AASHTO M294 / ASTM F2306 (Corrugated HDPE pipe for drainage applications).

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025