Oct . 13, 2025 14:35 Back to list

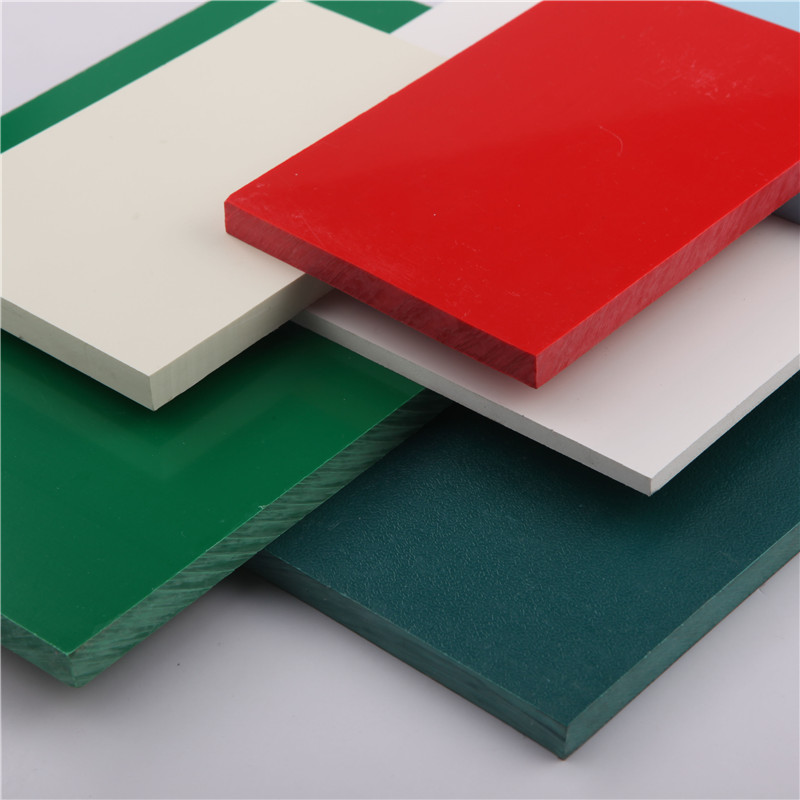

PVC Rigid Sheet(UV Stabilized) - Weatherproof, Printable

Field Notes on PVC Rigid Sheet(UV Stabilized): What Buyers Actually Care About in 2025

I’ve walked enough factory floors to know: not all rigid PVC is the same, and UV is the quiet killer. In outdoor signage, chemical enclosures, even farm infrastructure, sunlight can chalk and embrittle basic PVC in a year or two. That’s why buyers keep asking for PVC Rigid Sheet(UV Stabilized)—and, to be honest, for good reason. Below is a condensed insider’s guide based on current projects, lab data, and what many customers say after six months in the field.

Industry trends: durability over headline specs

Outdoor plastics buyers are pivoting from peak strength promises to retention metrics: how much tensile and color performance remains after UV exposure. Surprisingly, procurement teams now ask for QUV test curves, not just MSDS sheets. Also trending: Ca-Zn stabilization (RoHS-friendly), matte anti-glare surfaces for signage, and tighter color matching (RAL/Pantone) in small batches.

Key applications (from recent orders)

- Outdoor signage, display boards, wayfinding systems

- Facade cladding, equipment guards, rooftop duct skins

- Chemical tank liners, splash guards (acid/alkali areas)

- Cleanroom tool panels, electrical enclosures (low smoke/halogen concerns vary)

- Agriculture partitions, livestock housing panels

Product specifications (real-world ranges)

| Parameter | Typical values / options |

| Thickness | 1–30 mm standard; custom up to ≈50 mm on request |

| Width by thickness | 1–3 mm: 1000–1300 mm; 4–20 mm: 1000–1500 mm; 25–30 mm: 1000–1300 mm; 35–50 mm: ≈1000 mm (special-order) |

| Length / standard sizes | Any length; common: 1220×2440 mm, 1000×2000 mm, 1500×3000 mm |

| Surface / colors | Glossy, matt, embossed; dark grey (RAL7011), light grey, black, white, blue, green, red, custom colors |

| Density | ≈1.40 g/cm³ (PVC-U) |

| Mechanical (ref.) | Tensile 45–55 MPa (ASTM D638); Flexural 80–100 MPa (ASTM D790); Izod ≈4–8 kJ/m² (ASTM D256) — real-world use may vary |

| UV performance | QUV (ISO 4892-2 / ASTM G154): 1000 h, ΔE typically <5; tensile retention ≈85–95% depending on color/finish |

Process flow (how it’s made, briefly)

Materials: PVC resin (K≈57–67), Ca-Zn heat stabilizers, UV absorbers, rutile TiO₂, impact modifiers, lubricants, pigments. Methods: high-intensity compounding → twin-screw extrusion → calendaring/pressing → surface texturing (gloss/matt/emboss) → cooling → sizing → trimming. Tests: ASTM D638/D790/D256, ISO 62 (water absorption), ISO 4892-2 (UV), dimensional tolerance checks, color ΔE against RAL/Pantone. Service life: outdoors ≈5–10 years (temperate); tropical/high-UV zones trend lower unless thickness and TiO₂ loading are increased.

Why customers pick PVC Rigid Sheet(UV Stabilized)

- Better colorhold and less chalking versus standard PVC

- Rigid, easy to fabricate (cut, rout, bond, thermoform at modest temps)

- Chemical resistance against acids/alkalis commonly found in plants

- RoHS/REACH-friendly Ca-Zn systems available

Vendor snapshot (what to look for)

| Vendor | MOQ | Lead time | Tolerance | UV warranty | Certifications | Customization |

| Lida Plastic (Hebei) | ≈1–2 tons | 10–20 days | Thickness ±0.2–0.5 mm (by gauge) | Project-specific (ask for QUV data) | ISO 9001, RoHS/REACH statements | Color, emboss, cut-to-size |

| Generic importer | Varies | Stock-dependent | Mixed | Often unspecified | Basic CoC | Limited |

| Local fabricator | Low | Quick | Good on cut parts | Depends on source | Fabrication certs | Excellent post-processing |

Customization tips

- For coastal installs, ask for higher TiO₂ and darker greys; it seems that color drift is lower.

- Request QUV-B 313 nm and QUV-A 340 nm curves; different spectra matter.

- Matte/embossed surfaces reduce glare and scuff visibility on signage.

Micro case studies

- Transit signage, SE Asia: after 2000 h QUV-A, ΔE≈3.6 and tensile retention ≈90%; field check at 12 months showed no chalking.

- Plating room splash guards: alkaline mist exposure; panels held gloss and dimensional stability, weekly wipe-down only.

Compliance note: UL 94 V-0, food-contact, or specialized cleanroom grades can be supplied on request with supporting test reports; always verify per application.

References

- ISO 4892-2: Plastics — Methods of exposure to laboratory light sources (QUV-A/UV-B).

- ASTM D1784: Rigid PVC compounds and chlorinated PVC (cell classification guidance).

- ASTM D638/D790/D256: Standard tensile, flexural, and impact test methods for plastics.

- Directive 2011/65/EU (RoHS) and REACH Annex XVII — hazardous substance restrictions for materials.

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025

-

HDPE Water Pipe - Durable, Cost-Effective Water Solutions for Global Needs

NewsNov.22,2025