জুন . 06, 2025 14:28 ফিরে তালিকায়

Pipe Fittings: Essential Components for Secure and Efficient Plumbing Systems

Whether you are building a residential plumbing system, constructing a chemical plant, or setting up agricultural irrigation, pipe fittings play an indispensable role. These small yet critical components are used to connect straight pipe or tubing sections, adapt to different sizes or shapes, and regulate the flow of fluids.

Among the wide range of options available, PVC pipe fittings এবং HDPE pipe fittings are two of the most popular choices for modern piping systems. Known for their durability, chemical resistance, and ease of installation, these fittings are suitable for both domestic and industrial applications.

What Are Pipe Fittings?

Pipe fittings are components used to join pipes together or to change the direction, flow rate, or configuration of a pipeline. Common types of fittings include:

Elbows (for changing direction)

Tees (for branching)

Reducers (for connecting different pipe sizes)

Couplings (for joining two pipes)

Caps and Plugs (to close pipe ends)

Unions (for quick disconnect)

Fittings are manufactured in a variety of materials to match the pipe type and meet specific pressure, temperature, and fluid handling requirements.

PVC Pipe Fittings: Lightweight and Versatile

PVC pipe fittings are made from polyvinyl chloride (PVC), a lightweight and durable plastic widely used in plumbing and drainage systems. These fittings are known for their:

Corrosion resistance

Low cost

Ease of assembly

Long service life

Common Applications of PVC Pipe Fitting

PVC fittings are commonly found in:

Residential water supply systems

Irrigation systems

Drainage and sewage infrastructure

Chemical processing plants (with special grades)

PVC pipe fittings come in both schedule 40 (standard strength) and schedule 80 (high-pressure applications) to suit different system demands. They are joined through solvent welding, threading, or mechanical connections.

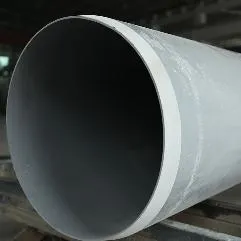

HDPE Pipe Fittings: Tough and Flexible

HDPE pipe fittings are made from high-density polyethylene, a thermoplastic with excellent impact resistance, flexibility, and corrosion resistance. These fittings are favored in industrial, agricultural, and municipal applications.

Key Benefits of HDPE Pipe Fitting

High durability: Resistant to cracking and impact

Corrosion-free: Immune to chemical and biological attacks

Flexible: Adapts well to underground installations and seismic movements

Leak-free joints: Through butt fusion, electrofusion, or compression fittings

Applications of HDPE Pipe Fittings

Water supply and distribution

Wastewater systems

Mining and slurry lines

Gas distribution

Agricultural irrigation systems

Because HDPE pipe fittings are typically joined through heat fusion, they create a joint that is as strong as the pipe itself, offering long-term reliability.

PVC vs HDPE Pipe Fittings: A Comparison

|

Feature |

PVC Pipe Fitting |

HDPE Pipe Fitting |

|

Material |

Polyvinyl Chloride |

High-Density Polyethylene |

|

Cost |

Lower |

Slightly higher |

|

Joining Method |

Solvent cementing or threading |

Heat fusion (butt/electrofusion) |

|

Flexibility |

Rigid |

Flexible |

|

Temperature Range |

Moderate |

Wider range |

|

Chemical Resistance |

Good |

Excellent |

|

Typical Use |

Residential, irrigation, drainage |

Industrial, gas, waterworks |

Your choice between PVC pipe fittings এবং HDPE pipe fittings should depend on the application, installation environment, budget, and long-term performance expectations.

How to Select the Right Pipe Fitting

When choosing the right pipe fitting, consider the following factors:

Pipe Material Compatibility – Always match the fitting material to the pipe (PVC-to-PVC, HDPE-to-HDPE).

Application Type – Determine if the system will carry water, chemicals, gas, or slurry.

Pressure and Temperature Ratings – Choose fittings that can withstand the system’s demands.

Joining Method – Confirm whether the system will use solvent weld, heat fusion, or mechanical connections.

Standards and Certifications – Make sure the fittings comply with regional or international standards (e.g., ASTM, ISO, DIN).

Advantages of Using Quality Pipe Fittings

High-quality pipe fittings help ensure:

Leak-free performance

Efficient flow management

Extended system life

Ease of maintenance

Safety in high-pressure environments

Substandard fittings can cause leaks, contamination, or system failure, leading to costly repairs and downtime.

Pipe Fittings FAQs

Q1: Can I use PVC pipe fittings for hot water?

A: Standard PVC is not suitable for hot water. Use CPVC (Chlorinated PVC) for higher temperature resistance.

Q2: Are HDPE fittings better than PVC for underground use?

A: Yes. HDPE pipe fittings are more flexible and resistant to ground movement, making them ideal for buried applications.

Q3: How are HDPE fittings joined?

A: Through heat fusion methods like butt welding or electrofusion, creating strong, leak-proof joints.

Q4: What are common sizes for pipe fittings?

A: They range from 1/2 inch to 48 inches or more, depending on the material and application.

Q5: Do pipe fittings come with pressure ratings?

A: Yes. Both PVC pipe fittings এবং HDPE pipe fittings are rated for specific pressure limits—check manufacturer specifications.

Pipe fittings are the silent heroes of any fluid transportation system. Whether you choose PVC pipe fittings for their affordability and ease of use or opt for HDPE pipe fittings for their strength and flexibility, making the right choice ensures your system runs efficiently and safely. By understanding the differences, applications, and benefits of each type, you can select the ideal solution for your next plumbing, industrial, or infrastructure project.

If you need help selecting or sourcing quality pipe fittings, reach out to a trusted supplier who can guide you based on your unique requirements.

-

Welding Rods: The Backbone of Plastic Welding Applications

খবরJun.06,2025

-

PVC Sheet: A Versatile Material for Modern Construction and Design

খবরJun.06,2025

-

PVC Rod: A Reliable and Versatile Material for Industrial Applications

খবরJun.06,2025

-

Pipe Fittings: Essential Components for Secure and Efficient Plumbing Systems

খবরJun.06,2025

-

HDPE Sheet: Durable, Versatile, and Eco-Friendly Plastic for All Applications

খবরJun.06,2025

-

HDPE Pipe Solutions: Durable, Versatile, and Built to Last

খবরJun.06,2025