Oct . 19, 2025 14:00 Back to list

PP Rigid Sheet (Glossy Surface) – Food Safe, Thermoformable

A Practical Buyer’s Guide to PP rigid sheet(glossy surface)

If you fabricate tanks, build cleanroom partitions, or simply need a corrosion-proof panel that looks sharp under overhead lights, you’ve probably run into glossy PP. To be honest, polymer sheets can feel interchangeable until you touch them. The gloss finish here is not just about looks; it reduces dirt pickup and, many customers say, “wipes clean in one pass,” which matters in food and lab environments.

What’s driving demand right now

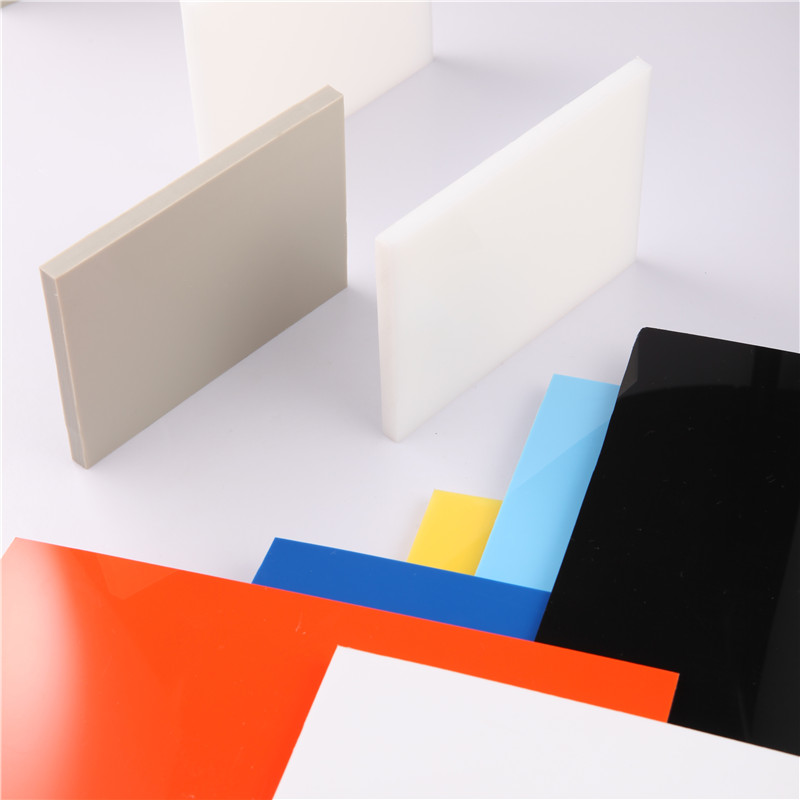

Three things: chemical processing upgrades, cleaner production lines, and a push for recyclable materials. Polypropylene is fully recyclable, and—surprisingly—fabricators are asking for color-coded panels (light blue for hygiene zones, grey for utilities) to streamline audits. The shiny surface helps with visual inspection. I guess that’s why glossy PP is winning tenders in plating plants and food secondary packaging.

Key specs at a glance

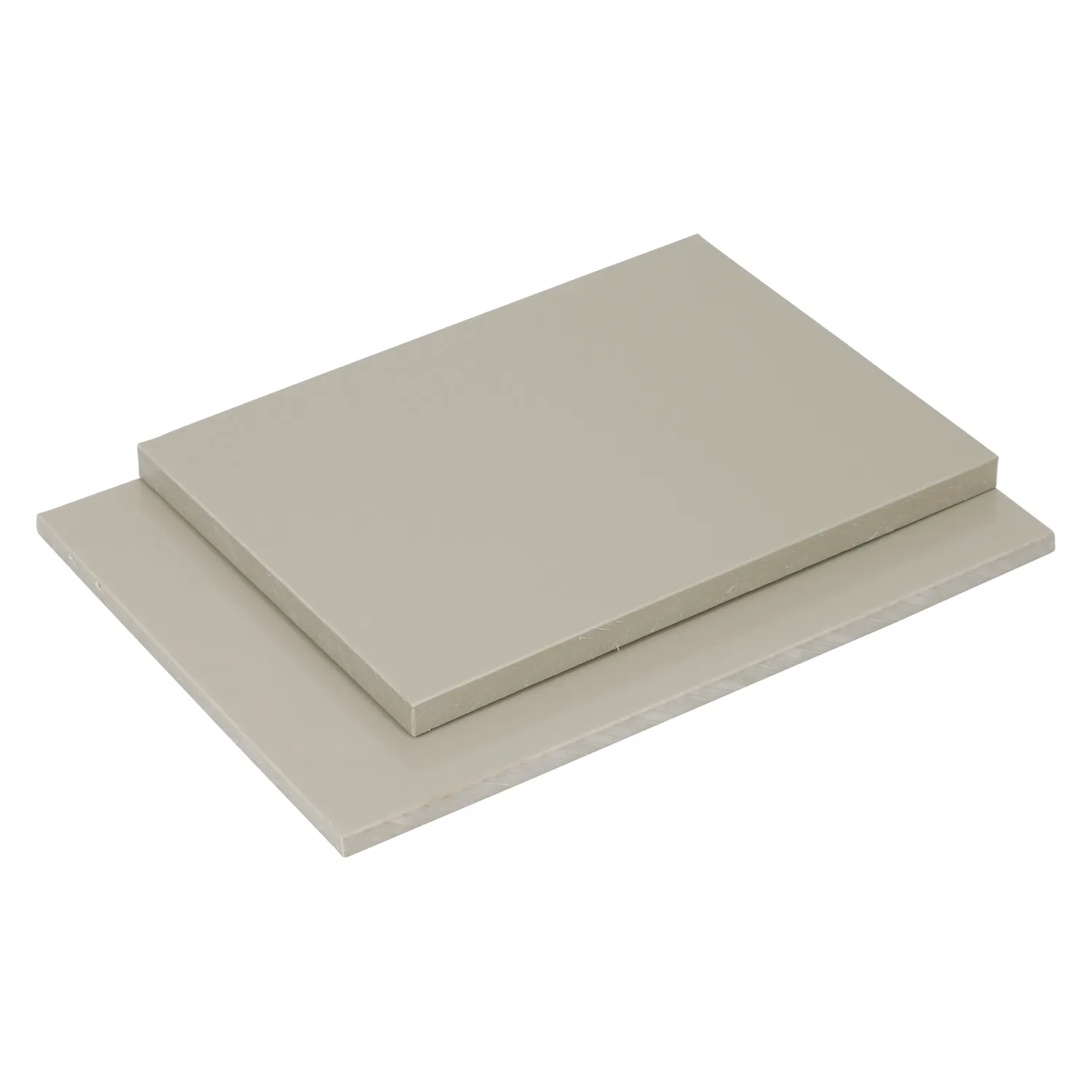

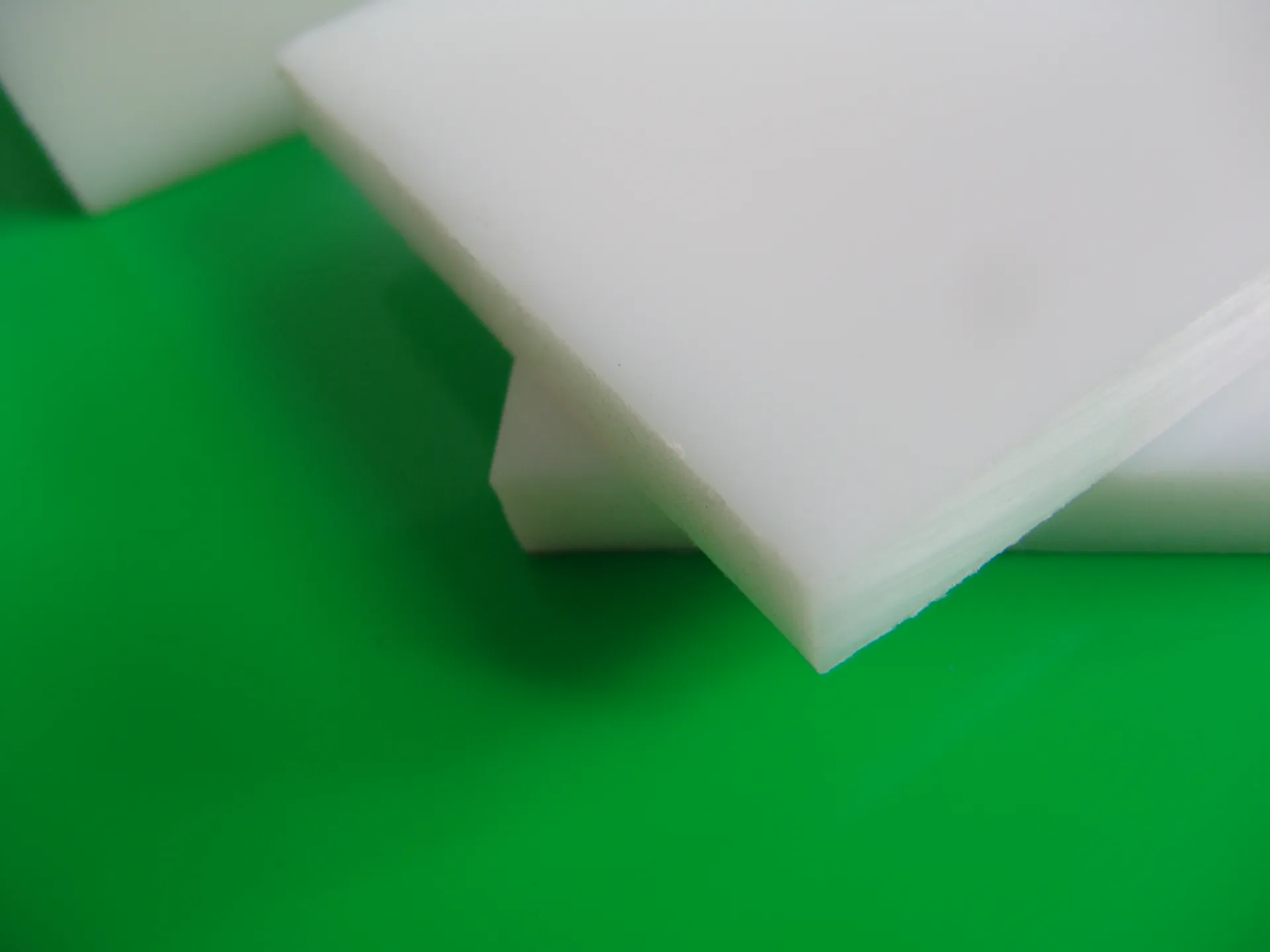

PP rigid sheet(glossy surface) is a semi-crystalline polypropylene, typically a homopolymer tweak with ≈1–4% ethylene to curb brittleness above 0°C. Cut-to-size service is common, which saves scrap on-site.

| Thickness | 2–40 mm |

| Width | 2–20 mm: 1000–2400 mm; 25–40 mm: 1000–1500 mm |

| Length | Any; cut-to-size available |

| Density | ≈0.90 g/cm³ |

| Tensile strength (ISO 527) | 28–35 MPa (real-world use may vary) |

| Flexural modulus (ISO 178) | ≈1200–1500 MPa |

| Vicat softening (ISO 306) | ≈150 °C |

| HDT (ISO 75) | ≈100–110 °C |

| Surface gloss (60°) | ≈75–95 GU |

| Colors | Natural, grey (RAL7032), black, light blue, yellow, custom |

How it’s made (and tested)

Resin selection (homo PP with ethylene copolymer), drying, then extrusion through a flat die. The glossy face is calendered on a polished chill roll; thickness is laser-monitored. Optional corona treatment boosts printability. Afterwards: edge-trim, anneal (reduces internal stress), protective film, palletize. QA pulls samples for ISO 527 tensile, ISO 178 flex, ISO 306 Vicat, ISO 868 hardness, and ISO 62 water absorption. Typical service life: 8–15 years indoors; outdoors needs UV-stabilized grades (3–5 years, climate-dependent).

Where it’s used

- Chemical tank linings, fume hood panels, ductwork cladding.

- Cleanroom walls and machine guards (gloss helps housekeeping).

- Food secondary processing tables and splash guards (FDA-grade on request).

- Wet benches, plating lines, acid/alkali environments.

Vendor snapshot (indicative)

| Vendor | Thickness | Colors | Certs | Lead time | Notes |

|---|---|---|---|---|---|

| Lida Plastic (Hebei, CN) | 2–40 mm | Std + custom | ISO 9001, RoHS/REACH | ≈7–12 days | Cut-to-size, CNC |

| EU brand | 2–30 mm | Std palette | ISO/EN, food grades | ≈2–4 weeks | Premium pricing |

| Local fabricator | Cut from stock | Limited | Varies | Same-week | Convenient small MOQ |

Customization

PP rigid sheet(glossy surface) can be CNC-cut, butt-welded, thermoformed, and supplied with matching PP welding rods. Options: UV-stabilized grade, anti-static, protective PE film, embossed back, and RAL-matched colors for line zoning.

Quick case notes

Electroplating OEM (SEA): swapped fiberglass panels for PP rigid sheet(glossy surface). Result: 22% faster wipe-downs, fewer micro-cracks near bolt holes after 8 months (ISO 527 pull tests on retained samples stayed within spec).

Food packaging site (EU): installed light-blue PP rigid sheet(glossy surface) splash guards. QA liked the visible cleanliness; RoHS/REACH declarations and optional FDA 21 CFR 177.1520 compliance supported the audit. Lead time was, actually, nine days door-to-door.

Factory origin: No.316 Pingan West Street, Shunping County, Baoding City, Hebei, China 072250

Compliance on request: ISO 9001, RoHS, REACH SVHC screening; food-contact grades available where applicable. Always validate with your end-use standard.

References

- ISO 527-1:2019 Tensile testing of plastics. https://www.iso.org/standard/75824.html

- ISO 178:2019 Flexural properties. https://www.iso.org/standard/76177.html

- ISO 306:2013 Vicat softening temperature. https://www.iso.org/standard/51989.html

- ASTM D638-22 Standard Test Method for Tensile Properties of Plastics. https://www.astm.org/d0638-22.html

-

Efficient HDPE Pipe Drip Irrigation Systems for Sustainable Farming

NewsNov.21,2025

-

HDPE Rain Pipe Solutions: Durable & Sustainable Rainwater Management

NewsNov.20,2025

-

HDPE Pipe for Drip Irrigation – Sustainable Water Solutions for Agriculture

NewsNov.20,2025

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025