Dec . 05, 2024 10:47 Buyela ohlwini

Welding Rod Safety: Protecting Yourself and Your Work Environment

Welding is a versatile and essential skill in industries ranging from construction to manufacturing. However, the process involves risks, especially when handling various types of welding rods. This article explores essential guidelines to ensure safety without compromising welding quality.

Understanding Welding Rod Types and Their Hazards

Different Welding Rod Types serve various purposes, but they also come with unique risks. For instance, flux-coated rods used in shielded metal arc welding can emit hazardous fumes when exposed to high temperatures. Specialty rods like Hard Facing Welding Rods, designed for wear resistance, require higher heat levels, increasing the potential for burns.

Proper storage is critical to maintaining welding rod integrity and safety. Store rods in a dry, temperature-controlled environment to prevent moisture absorption, which can cause rod degradation and lead to defects in the weld. Handling rods with clean gloves reduces contamination and ensures better arc stability during welding.

Managing Fumes from Plastic Welding Rods

Plastic Welding Rods are used for repairing and fabricating thermoplastic materials. However, welding plastic can produce toxic fumes, especially when working with materials like PVC or polypropylene.

To minimize exposure, always weld in a well-ventilated area or use an exhaust ventilation system. A properly fitted respirator designed for welding applications can provide additional protection. Monitor the temperature carefully; overheating Plastic Welding Rods not only produces harmful fumes but also weakens the bond strength of the weld.

Simplifying Safety with Simple Welding Rods

Simple Welding Rods, often used for general-purpose repairs and smaller projects, are less hazardous than some specialized rods but still require caution. These rods are frequently applied in home workshops, where safety measures are sometimes overlooked.

Ensure that your workspace is clear of flammable materials. Even a stray spark can ignite fires. Always wear protective clothing, including a welding helmet with the appropriate shade lens, fire-resistant gloves, and a flame-retardant jacket. For added safety, consider keeping a fire extinguisher nearby and inspecting it regularly.

Handling High-Temperature Applications with Hard Facing Welding Rods

Hard Facing Welding Rods are designed to withstand extreme wear and tear, making them ideal for heavy-duty industrial applications. However, the intense heat required for their use presents specific safety challenges.

Preheating the base metal before welding can enhance the bond strength but also raises the risk of burns. Use insulated gloves and handle materials with tongs or other tools to avoid direct contact. Inspect your welding equipment regularly to ensure it can handle the demands of hard-facing applications without failure. Always ground the welding machine properly to avoid electrical shocks.

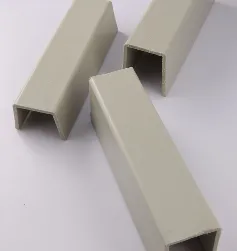

Specialized Applications of PVC Square Rods

PVC Square Rods are versatile components in fabrication projects, often used for structural reinforcement or decorative purposes. While they may seem less risky compared to traditional metal rods, working with PVC still requires attention to safety.

Cutting or welding PVC Square Rods generates fine dust and fumes that can irritate the respiratory system. Use a dust mask and goggles to protect yourself from airborne particles. When bonding PVC, avoid using excessive adhesives or solvents, as these can release volatile organic compounds (VOCs). Following the manufacturer's guidelines for safe handling ensures optimal results without compromising safety.

Welding is a powerful tool for creating and repairing structures, but safety must always remain a top priority. Whether using general-purpose Welding Rod Types, specialized Hard Facing Welding Rods, or innovative materials like PVC Square Rods, understanding and implementing safety measures is essential. By investing in proper protective equipment, maintaining a clean and organized workspace, and staying informed about the specific risks associated with each type of welding rod, you can ensure both the quality of your work and the well-being of everyone involved. Let safety be the foundation of every welding project you undertake.

-

Welding Rods: The Backbone of Plastic Welding Applications

IzindabaJun.06,2025

-

PVC Sheet: A Versatile Material for Modern Construction and Design

IzindabaJun.06,2025

-

PVC Rod: A Reliable and Versatile Material for Industrial Applications

IzindabaJun.06,2025

-

Pipe Fittings: Essential Components for Secure and Efficient Plumbing Systems

IzindabaJun.06,2025

-

HDPE Sheet: Durable, Versatile, and Eco-Friendly Plastic for All Applications

IzindabaJun.06,2025

-

HDPE Pipe Solutions: Durable, Versatile, and Built to Last

IzindabaJun.06,2025