Oct . 31, 2024 13:43 Back to list

Exploring the Features and Benefits of PP Plate Sheets in Various Applications

Understanding PP Plate Sheets Applications and Benefits

Polypropylene (PP) plate sheets have rapidly gained popularity across various industries due to their remarkable combination of properties. This versatile plastic material is derived from the polymerization of propylene monomers, resulting in a lightweight, robust option that can be custom-manufactured to meet diverse needs.

One of the standout features of PP plate sheets is their excellent chemical resistance. This attribute makes them suitable for a wide range of applications, particularly in environments where exposure to harsh chemicals is a concern. Industries such as pharmaceuticals, food processing, and chemical manufacturing often utilize PP sheets for storage tanks, containers, and equipment parts. Unlike many other materials, polypropylene does not corrode, ensuring longevity and reducing the need for frequent replacements.

Understanding PP Plate Sheets Applications and Benefits

Further enhancing their appeal, PP plate sheets are lightweight yet strong. This combination allows for easy handling and transportation, reducing shipping costs and labor intensity during installation. The strength-to-weight ratio ensures that structures and components made from PP sheets do not compromise on durability, even with their lightweight design.

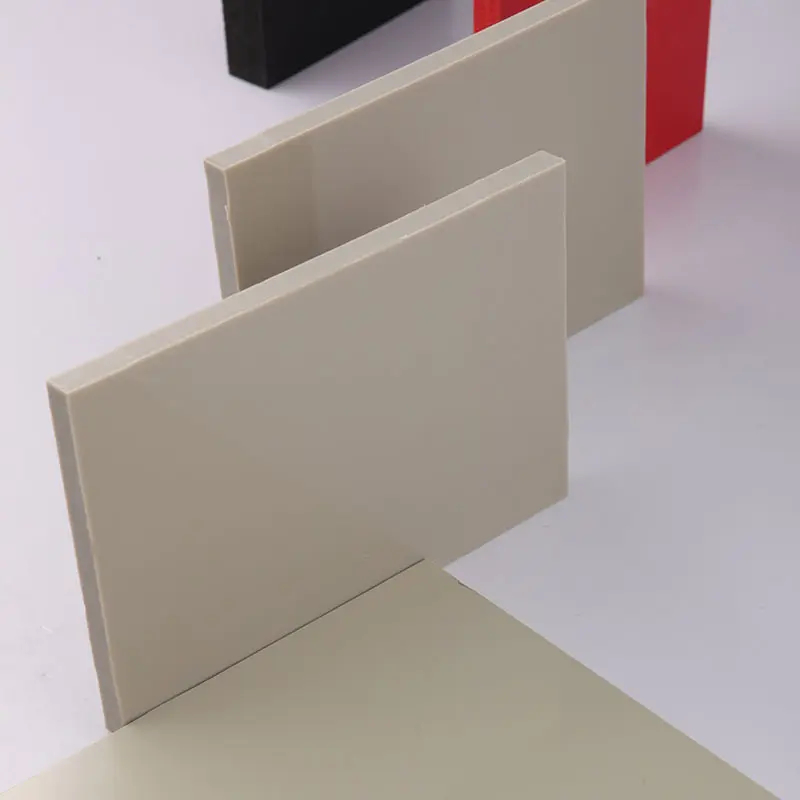

pp plate sheet

Another significant advantage is the ease of processing. PP sheets can be easily cut, welded, and shaped to meet specific design requirements. This flexibility makes them a popular choice for manufacturers who benefit from the ability to customize dimensions and functionalities. For those seeking aesthetic appeal, PP plates are available in various colors and can also be printed on, allowing for branding or decorative applications.

Moreover, PP plate sheets are environmentally friendly. They are recyclable and can be repurposed, reducing waste and supporting sustainable practices. As industries increasingly focus on minimizing their environmental impact, the use of materials like polypropylene is gaining traction.

Applications of PP plate sheets are diverse. In the construction industry, they can be used for interior wall panels, storage sheds, and even temporary partitions. In the automotive sector, PP sheets are utilized for interior components and dashboard coverings, contributing to weight reduction in vehicles, which is a critical aspect of enhancing fuel efficiency.

In conclusion, PP plate sheets offer a wide array of benefits, including chemical resistance, thermal stability, lightweight strength, processing versatility, and environmental sustainability. Their applications range from industrial to artistic, making them a valuable material in today's market. As technology and manufacturing processes advance, the potential for PP sheets will likely increase, opening doors for even more innovative uses in various sectors. For businesses and individuals alike seeking durable, flexible, and eco-friendly material solutions, PP plate sheets present an excellent option worth considering.

-

PVC Transparent Sheet Roll - Durable & Flexible PVC Plastic Sheet Roll for Industrial & Home Use

NewsJun.24,2025

-

High-Quality PVC PPR Pipes and Fittings Durable ERA PPR Solutions

NewsJun.10,2025

-

High-Quality Large HDPE Sheets & Large Diameter PVC Pipe Durable Large PVC Pipe Supplier

NewsJun.10,2025

-

High Density Polyethylene Cutting Board - Durable & Food Safe

NewsJun.09,2025

-

3 Inch PVC Pipe for Durable Irrigation Affordable & Reliable

NewsJun.09,2025

-

Premium PPR Plastic Water Pipe Fittings - Durable & Leak-Free

NewsJun.09,2025