Dec . 14, 2024 02:32 Back to list

Choosing the Right Welding Rods for PVC Projects and Applications

Understanding PVC Welding Rods Applications and Advantages

Welding rods play an essential role in the fabrication and repair of plastic materials, and among them, PVC (Polyvinyl Chloride) welding rods have emerged as a crucial component in various industries. These rods are specifically designed for welding PVC materials, commonly used in plumbing, construction, and electrical applications. This article explores the benefits, applications, and considerations surrounding PVC welding rods.

What are PVC Welding Rods?

PVC welding rods are thermoplastic materials that are used to create strong, permanent joints between PVC components. These rods typically consist of a mixture of PVC resin and plasticizers, ensuring flexibility while providing robustness. When heated, the rod melts and fuses with the base material, allowing for the creation of a solid joint upon cooling.

Applications of PVC Welding Rods

1. Plumbing and Piping One of the most prevalent applications of PVC welding rods is in the plumbing industry. PVC pipes are widely used for water supply and drainage systems due to their resistance to corrosive chemicals and lower installation costs. Welding rods aid in making durable connections that can withstand pressure and temperature variations.

2. Construction In the construction sector, PVC materials are used for windows, doors, and siding. PVC welding rods are utilized to join sections of these components, providing superior strength and weather resistance. This is particularly important in regions subject to extreme weather conditions, ensuring structures remain intact.

3. Electrical Applications PVC is also a popular choice for insulation and protective coverings for electrical wiring. The welding rods can be employed to repair damaged sections of PVC insulation, maintaining the integrity of electrical systems, and preventing exposure to hazardous conditions.

4. Signage and Displays The advertising and signage industry frequently utilizes PVC sheets for their lightweight yet durable characteristics. Welding rods are used to construct custom signs, displays, and promotional materials, allowing for intricate designs and branding.

5. Automotive Components The automotive industry often uses PVC materials for interior components. PVC welding rods facilitate the assembly of parts like dashboards and panels, ensuring they can endure daily wear and tear.

Advantages of Using PVC Welding Rods

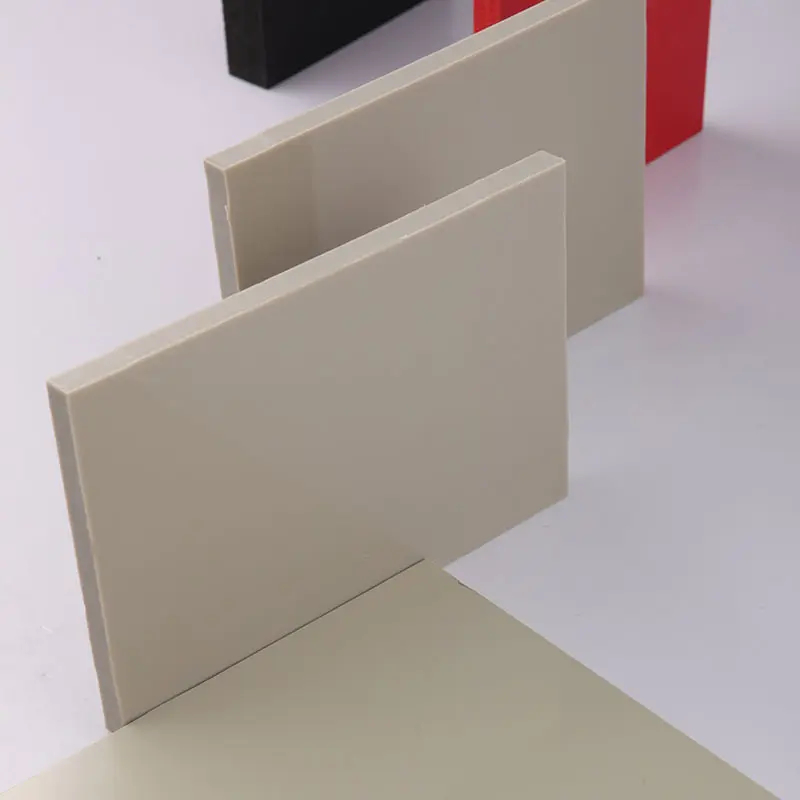

welding rod pvc

1. Durability One of the primary benefits of PVC welding rods is the durability of the joints they create. When properly welded, PVC joints can withstand high pressures and resist chemical exposure, which is critical in plumbing and industrial applications.

2. Cost-Effective Repairs Using PVC welding rods provides a cost-effective solution for repairs or modifications. Instead of replacing entire sections of a PVC structure, welding rods enable targeted repairs, saving time and resources.

3. Ease of Use PVC welding rods are relatively easy to use, making them accessible for DIY enthusiasts and professionals alike. Most welding processes involve heating the rod and the base material, allowing for straightforward applications.

4. Versatility PVC welding rods are compatible with various types of PVC materials, making them versatile for many applications across different industries.

5. Environmental Resistance PVC is known for its resistance to moisture, corrosion, and UV light, which enhances the longevity of anything constructed with it. Welding rods help maintain these qualities, ensuring the performance of the final product.

Considerations When Using PVC Welding Rods

While PVC welding rods have numerous advantages, certain considerations should be kept in mind

- Proper Equipment Using the right welding equipment is crucial for effective results. Whether using a hot air welder or a specific welding gun, the temperature and method of application must be carefully controlled to avoid damaging the materials.

- Safety Precautions Always prioritize safety. When welding PVC, ensure proper ventilation as fumes can be hazardous. Wearing protective gear is advisable to mitigate risks.

- Material Compatibility While PVC welding rods work well with PVC materials, ensure compatibility with other types of plastics if involved in multi-material constructions.

In conclusion, PVC welding rods are fundamental in a multitude of applications due to their strength, cost-effectiveness, and ease of use. Understanding their benefits and proper applications ensures optimal use in various industries, making them a valuable tool for professionals and DIY enthusiasts alike.

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025