Nov . 27, 2024 21:48 Back to list

Applications and Advantages of Polyethylene Pipe Fittings in Various Industries

Understanding Polyethylene Pipe Fittings Types, Applications, and Benefits

Polyethylene pipe fittings play an essential role in various plumbing, irrigation, and industrial applications. Made from high-density polyethylene (HDPE) and low-density polyethylene (LDPE), these fittings offer various advantages over traditional materials like metal and PVC due to their flexibility, corrosion resistance, and overall durability. In this article, we will explore the types, applications, and numerous benefits of polyethylene pipe fittings.

Types of Polyethylene Pipe Fittings

Polyethylene pipe fittings come in several types, each designed for specific functions. The most common fittings include

1. Elbows Used to change the direction of a pipe. The most common angles are 90 degrees and 45 degrees. 2. Tees Allow for the connection of three sections of pipe, creating a T-shape that can divert flow in multiple directions.

3. Reducers Used to connect pipes of different diameters, allowing for a smooth transition in fluid systems.

4. Couplings Deliver a simple method for connecting two sections of pipe to extend the length of the line.

5. Caps and Plugs Used to seal the ends of pipes, either to terminate a run of piping or to prevent the flow of fluid.

6. Adapters Allow for the transition between polyethylene pipes and different materials like metal or PVC.

7. Flanges Used for connecting pipes to equipment or other piping systems, these fittings enable easy maintenance and removal.

Applications of Polyethylene Pipe Fittings

Due to their versatility and reliability, polyethylene pipe fittings find applications across various sectors, including

2. Irrigation Systems In agriculture, these fittings are used to connect irrigation systems, allowing for efficient water distribution across large fields, especially in drip irrigation setups.

polyethylene pipe fittings

3. Natural Gas Distribution High-density polyethylene is used in natural gas piping systems, making use of its ability to withstand the high pressures associated with gas distribution.

4. Sewage Systems In sewerage systems, polyethylene pipe fittings are used extensively due to their resistance to corrosion and chemical interactions with waste materials.

5. Industrial Applications Various industries use HDPE fittings for transporting chemicals, where corrosion resistance and durability are crucial.

Benefits of Polyethylene Pipe Fittings

The advantages of using polyethylene pipe fittings over traditional materials include

1. Corrosion Resistance Unlike metal fittings, polyethylene does not corrode, making it ideal for environments that expose the fittings to harsh chemicals or moisture.

2. Flexibility Polyethylene fittings offer a degree of flexibility, allowing them to be installed in tight spaces and adapting to ground movement without cracking or breaking.

3. Lightweight Polyethylene fittings are significantly lighter than metal fittings, resulting in reduced shipping and handling costs, as well as easier installation.

4. Cost-Effectiveness The long service life of polyethylene fittings, combined with their durability and low maintenance needs, results in cost savings over time.

5. Ease of Installation Many polyethylene fittings utilize heat fusion techniques for seamless connections, which can reduce installation time and eliminate the need for glue or solvents.

6. Environmental Impact Many polyethylene fittings are made from recyclable materials, contributing to a more sustainable construction and manufacturing process.

Conclusion

Polyethylene pipe fittings are a vital component in modern plumbing and industrial applications, offering flexibility, durability, and cost-effectiveness. As industries continue to look for materials that meet environmental and regulatory standards, the use of polyethylene fittings is likely to increase. With their myriad benefits, it's no wonder that they are becoming the preferred choice for many applications in diverse sectors. Understanding the types of fittings available and their respective applications can help in making informed decisions for any plumbing or industrial project.

-

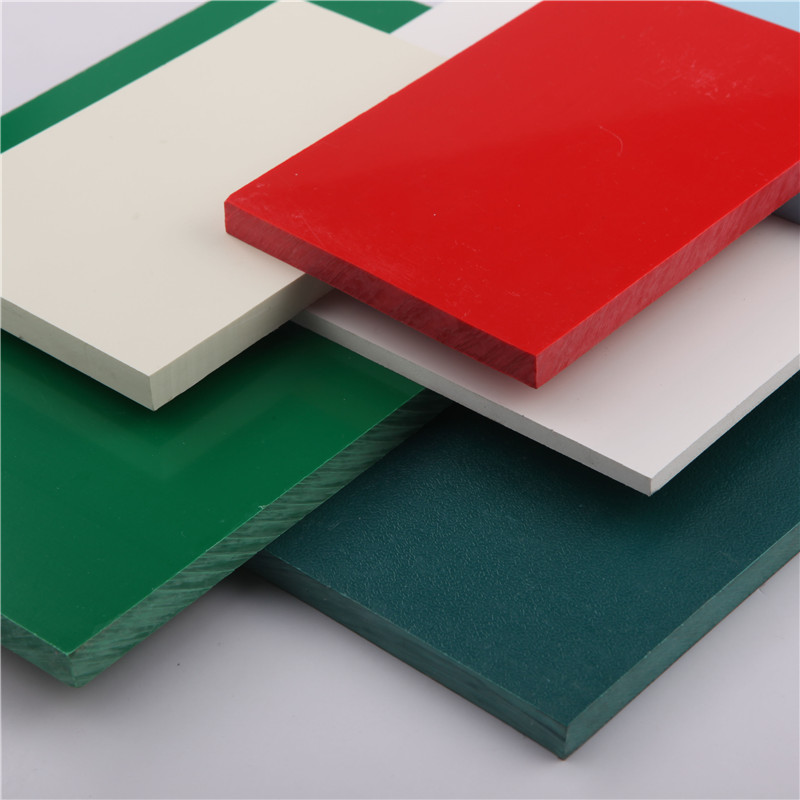

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025