Гру . 11, 2024 09:50 Back to list

Understanding Density Characteristics of HDPE Sheets for Various Applications

Understanding the Density of HDPE Sheets

High-density polyethylene (HDPE) is a type of thermoplastic made from petroleum. It is known for its high strength-to-density ratio, making it a popular choice in various industrial applications. When discussing HDPE sheets, one of the key physical properties to consider is density. Density is the measure of mass per unit volume, and it is crucial in applications where weight, buoyancy, and structural integrity are critical.

What is HDPE?

HDPE is a versatile plastic that is produced through the polymerization of ethylene. It is characterized by its density, which is generally around 0.93 to 0.97 grams per cubic centimeter (g/cm³). This relatively low density is one of the reasons HDPE is so widely used; it is lightweight, yet durable and strong. This combination allows HDPE sheets to be utilized in a wide array of environments—from household products to industrial applications.

Importance of Density

The density of HDPE sheets is an essential factor that influences their mechanical properties, thermal stability, chemical resistance, and overall usability. When designing or selecting HDPE materials for a specific application, understanding the density can help in predicting how the material will perform under different conditions.

1. Mechanical Strength The density of HDPE contributes to its mechanical strength. Heavier sheets are often perceived as being more robust, although other factors such as thickness and orientation of the material also play significant roles. Manufacturers can create sheets of varying densities to meet the requirements of specific applications.

2. Thermal Stability Density affects the thermal characteristics of HDPE. Higher-density HDPE tends to provide better resistance to heat and can withstand higher temperatures before deforming. Thus, when selecting an HDPE sheet for applications that involve exposure to high temperatures, density should not be overlooked.

hdpe sheet density

3. Chemical Resistance Density also influences the chemical resistance of HDPE. Thicker sheets typically provide better barriers against corrosive substances. This property makes HDPE sheets suitable for chemical storage tanks, liners, and other applications where chemical exposure is likely.

4. Weight Considerations In many applications, particularly in manufacturing and transportation, the weight of the material is paramount. Lower-density HDPE sheets can significantly reduce shipping costs and ease the handling of materials in assembly processes.

5. Customization Knowing the density of HDPE sheets allows manufacturers to customize their products for specific applications. For instance, a manufacturer may modify the density for applications that require buoyancy, lightweight construction, or increased strength.

Common Applications of HDPE Sheets

HDPE sheets are used across various industries, thanks to their favorable properties. Some common applications include

- Packaging HDPE is commonly used in the production of bottles, containers, and various packaging materials due to its lightweight and strength. - Construction In construction, HDPE sheets are used for roofing membranes, geomembranes for landfills, and insulation. - Automotive The automotive industry utilizes HDPE sheets for interior panels, fuel tanks, and other components that benefit from the material's lightweight and durable nature. - Agriculture HDPE is used in the production of various agricultural products, including liners for irrigation systems and durable storage containers.

Conclusion

The density of HDPE sheets plays a pivotal role in determining their suitability for various applications. By understanding the principles behind density and its effects on mechanical properties, thermal resistance, and overall performance, industries can better utilize HDPE to meet their specific needs. As technology advances, the ability to tailor the density of HDPE sheets will only enhance their versatility and expand their applications even further. Whether it’s for environmental sustainability, cost-effectiveness, or enhanced performance, the study of HDPE density continues to be a significant component of material science and engineering.

-

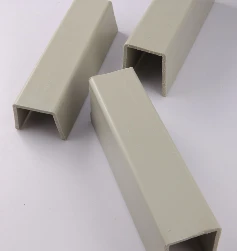

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025