دېكابىر . 19, 2024 16:14 Back to list

Choosing the Right Welding Rods for PVC Projects and Applications

Welding Rods for PVC A Comprehensive Guide

Welding rods play a crucial role in the fabrication and repair of various plastic materials, especially Polyvinyl Chloride (PVC). As the demand for PVC applications continues to grow in industries such as construction, plumbing, and automotive, understanding the types of welding rods available for PVC and their respective uses is essential for achieving successful welding outcomes.

What Are PVC Welding Rods?

PVC welding rods are specialized materials used to join pieces of PVC through a process that involves heating the rod and the PVC to a melting point, causing them to fuse together upon cooling. These rods are typically composed of the same material as the PVC being welded, ensuring compatibility and a strong bond between the two surfaces.

Types of PVC Welding Rods

There are several types of welding rods available for PVC, each catering to specific applications and requirements

1. Extrusion Rods These rods are designed for the manual or automatic feeding into a welding machine. They are often used in the fabrication of larger PVC structures and can be formulated to match different grades of PVC.

2. Solid Rods Solid PVC welding rods are utilized in handheld welding processes. They are ideal for applications where precision and control are paramount, such as repairing tanks, pipes, and various PVC components.

3. Filler Rods These are used to fill gaps or defects in existing PVC structures. They are crucial in repair jobs where the base material may have been compromised.

4. Colored Rods Available in various colors, these rods are particularly useful when aesthetics are important, such as in displays or decorative items. The colored rods offer the same functionality as standard rods, but they can also enhance the visual appeal of the finished product.

Selecting the Right Welding Rod

Choosing the right PVC welding rod depends on several factors

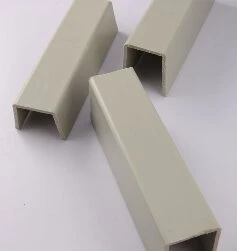

welding rods for pvc

- Material Compatibility It is essential to select a rod that matches the specific type of PVC being welded. This ensures a proper chemical bond and minimizes the risk of failure.

- Diameter and Length The size of the rod can influence the speed and efficiency of the welding process

. Longer rods may be required for larger projects, while shorter rods offer better control for fine detail work.- Welding Technique The method of welding also dictates the type of rod required. For instance, hot air welding requires specific rods optimized for such techniques, while solvent welding might call for a different formulation.

The Welding Process

Welding PVC generally involves several key steps

1. Preparation Clean the surfaces to be welded to remove any dirt, grease, or debris. This ensures a clean bond.

2. Heating Use a suitable welding tool to heat both the PVC surface and the welding rod.

3. Application Introduce the welding rod to the heated area, allowing it to melt into the joint.

4. Cooling Allow the welded area to cool naturally. Do not disturb the joint during this phase, as it is crucial for achieving a strong bond.

Conclusion

Welding rods for PVC are indispensable tools in the plastic fabrication industry. Understanding the various types and their specific applications can significantly improve the quality and durability of welded PVC joints. Whether for repair work or new constructions, selecting the right welding rod is essential for achieving a robust and aesthetically pleasing outcome. As technology advances, more specialized rods are becoming available, further enhancing the capabilities of PVC welding.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025