سېنتەبىر . 28, 2024 02:09 Back to list

Creating a Fiber Masked Sheet for Enhanced Performance and Protection

The Importance of PP Fibre Masked Sheets in Modern Applications

In today's manufacturing and construction landscapes, the choice of materials can significantly affect product quality, efficiency, and sustainability. One emerging material that has gained notable attention is the PP fibre masked sheet, or polypropylene fibre masked sheet. This innovative product offers a range of benefits that make it suitable for various applications across diverse industries such as construction, automotive, packaging, and specialty textiles.

Understanding PP Fibre Masked Sheets

PP fibre masked sheets are composite materials made from polypropylene fibers, which are known for their durability, flexibility, and resistance to various environmental factors. These sheets typically consist of a non-woven substrate that is treated with a masking layer, providing enhanced performance characteristics. The uniqueness of this material lies in its ability to provide a protective barrier while maintaining a lightweight profile, making it an attractive option for manufacturers looking to optimize their processes.

Key Characteristics

One of the most significant features of PP fibre masked sheets is their superior moisture resistance. In applications where water exposure is a concern, these sheets prevent the ingress of moisture, thus protecting underlying materials and prolonging their lifespan. Moreover, they exhibit excellent chemical resistance, making them ideal for use in environments where they may come into contact with harmful substances or solvents.

Another vital characteristic of this material is its thermal stability. PP fibre masked sheets can withstand a range of temperatures without degrading, which is particularly valuable in industries like automotive manufacturing where extremes in heat and cold are commonplace. Additionally, the sheets are lightweight and easy to handle, reducing the overall weight of end-products—a crucial factor in sectors focused on energy efficiency and sustainability.

Applications in Construction

pp fibre masked sheet

In the construction industry, PP fibre masked sheets serve as an effective vapor barrier, ensuring that structures remain dry and protected from moisture-related damage. They are often employed in roofing systems, wall assemblies, and insulation applications. The lightweight nature of these sheets also contributes to easier installation processes, reducing labor time and costs on construction sites.

Moreover, these sheets can be used as protective layers in various interior applications. For instance, they can act as a shield against dust and debris during construction or renovation projects, preserving the cleanliness and integrity of existing surfaces.

Role in the Automotive Industry

The automotive sector also benefits significantly from PP fibre masked sheets. These materials are incorporated into vehicle interiors, providing not only aesthetic appeal but also functional advantages such as sound dampening and heat insulation. By utilizing these sheets, manufacturers can enhance the overall comfort and safety of vehicles while also complying with increasingly stringent environmental regulations.

Sustainable Manufacturing

As industries worldwide shift towards sustainability, the utilization of PP fibre masked sheets presents an opportunity for eco-friendly manufacturing. Polypropylene is a recyclable material, meaning that these sheets can be recycled at the end of their life cycle, reducing waste and environmental impact. Furthermore, the durability and longevity of PP fibre masked sheets contribute to a more sustainable approach by minimizing the need for frequent replacements.

Conclusion

In conclusion, the versatility and beneficial characteristics of PP fibre masked sheets make them an essential material in various industries, particularly in construction and automotive applications. Their moisture resistance, chemical stability, and lightweight nature offer significant advantages that can lead to improved product performance and efficiency. Furthermore, with an increasing focus on sustainability, the recyclability and durability of these sheets provide a pathway for industries to pursue eco-friendly practices. As technology evolves and manufacturing needs expand, PP fibre masked sheets will undoubtedly play a crucial role in shaping the future of material science and industrial applications.

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

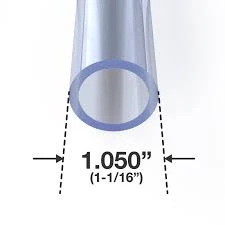

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025