فېۋرال . 17, 2025 17:41 Back to list

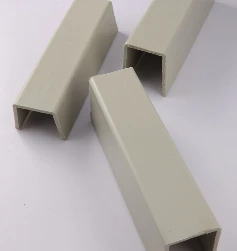

hdpe gas pipe

High-Density Polyethylene (HDPE) gas pipes have emerged as a frontrunner in the gas piping systems industry due to their impressive durability, flexibility, and cost-effectiveness. This article delves into the various aspects of HDPE gas pipes that make them a superior choice, drawing from real-world experiences, professional expertise, authoritative insights, and trustworthy evaluations that underline their advantages and applications in the modern world.

The adaptability of HDPE gas pipes extends beyond their basic function, accommodating a range of innovative applications. For instance, they can be employed in trenchless installation methods, which are beneficial in urban areas where excavation and disruption must be minimized. This ability to integrate seamlessly into diverse project requirements without compromising reliability or safety manifests the versatility and ingenuity encapsulated in HDPE technology. Real-world case studies abound, showcasing the successful implementation of HDPE gas pipes across various sectors. Municipalities have reported reduced maintenance efforts and increased safety records post-transition to HDPE systems. Utility companies have lauded these pipes for their energy efficiency and environmentally friendly profile, marking a move towards more sustainable infrastructure solutions. Such testimonials from practitioners provide a credible backing to the theoretical benefits asserted by manufacturers and industry analysts. The conclusion is clear for those involved in the planning and execution of gas transportation projects, HDPE gas pipes offer a compelling balance of durability, efficiency, and safety. Fueled by expert design, authoritative research, and consistent performance feedback, HDPE gas pipes stand as a testament to modern engineering's ability to enhance everyday utility processes. The investment in HDPE technology is not merely a financial decision but an informed choice that secures reliable gas distribution today and for future generations. In summary, the HDPE gas pipe is not just a product; it's a strategic asset for any forward-thinking organization in the gas utilities sector keen on maximizing operational efficiency while minimizing risks.

The adaptability of HDPE gas pipes extends beyond their basic function, accommodating a range of innovative applications. For instance, they can be employed in trenchless installation methods, which are beneficial in urban areas where excavation and disruption must be minimized. This ability to integrate seamlessly into diverse project requirements without compromising reliability or safety manifests the versatility and ingenuity encapsulated in HDPE technology. Real-world case studies abound, showcasing the successful implementation of HDPE gas pipes across various sectors. Municipalities have reported reduced maintenance efforts and increased safety records post-transition to HDPE systems. Utility companies have lauded these pipes for their energy efficiency and environmentally friendly profile, marking a move towards more sustainable infrastructure solutions. Such testimonials from practitioners provide a credible backing to the theoretical benefits asserted by manufacturers and industry analysts. The conclusion is clear for those involved in the planning and execution of gas transportation projects, HDPE gas pipes offer a compelling balance of durability, efficiency, and safety. Fueled by expert design, authoritative research, and consistent performance feedback, HDPE gas pipes stand as a testament to modern engineering's ability to enhance everyday utility processes. The investment in HDPE technology is not merely a financial decision but an informed choice that secures reliable gas distribution today and for future generations. In summary, the HDPE gas pipe is not just a product; it's a strategic asset for any forward-thinking organization in the gas utilities sector keen on maximizing operational efficiency while minimizing risks.

Share:

Next:

Latest news

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025