Дек . 13, 2024 00:38 Back to list

hdpe pipe jointing

The Importance of HDPE Pipe Jointing in Modern Infrastructure

High-Density Polyethylene (HDPE) pipes have revolutionized the way we approach piping solutions in various industries, including water, gas, sewage, and telecommunications. One of the critical aspects of utilizing HDPE pipes is the method of jointing, which ensures that the system remains leak-proof, durable, and efficient. In this article, we will discuss the significance of HDPE pipe jointing, the various methods employed, and the advantages it holds for modern infrastructure.

Understanding HDPE Pipes

HDPE is a thermoplastic polymer made from petroleum, known for its high strength-to-density ratio. These pipes are highly resistant to various chemicals and environmental stresses, making them ideal for transporting liquids and gases. The flexibility and lightweight nature of HDPE pipes enable easier handling and installation, significantly reducing labor costs. However, the performance of these pipes heavily relies on the integrity of their joints.

Importance of Proper Jointing

Proper jointing of HDPE pipes is crucial for several reasons

1. Leak Prevention A well-executed joint minimizes the risk of leaks, which can lead to significant water loss, environmental damage, or service disruptions. Water leaks can also contribute to soil erosion and reduce the structural integrity of surrounding infrastructure.

2. Structural Integrity Jointing methods must withstand internal pressure and external loads. Poorly executed joints can lead to pipe sagging or collapse, compromising the entire system.

3. Longevity HDPE pipes are designed to last for decades. However, improper jointing can significantly reduce their lifespan. Ensuring that joints are solid and resistant to wear and tear is vital for long-term reliability.

4. Ease of Maintenance Well-joined HDPE pipe systems are easier to inspect and maintain. Accessing poorly joined sections can be troublesome, leading to higher maintenance costs and downtime.

Methods of Jointing HDPE Pipes

There are several methods for jointing HDPE pipes, each with its own advantages and suitability based on the application

1. Electrofusion This method involves the use of an electric current to heat the pipe fittings, causing them to fuse together. Electrofusion is known for creating strong, permanent joints and is widely used in water and gas distribution systems.

hdpe pipe jointing

2. Butt Fusion In this process, the ends of two pipes are heated until they reach the appropriate temperature for fusion. This method is often used for larger diameters and is valued for its cost-effectiveness and reliability.

3. Socket Fusion This technique involves heating the outside of one pipe and the inside of a fitting so that they can be fused together. Socket fusion works well for smaller diameter pipes and offers a simple installation process.

4. Mechanical Joints While not as commonly used as fusion methods, mechanical joints can be employed for temporary connections or in situations where fusion methods are impractical. These joints utilize clamps, bolts, and gaskets to create a seal.

Advantages of HDPE Pipe Jointing

The jointing of HDPE pipes presents numerous advantages, contributing to the overall effectiveness of a piping system

- Flexibility HDPE pipe jointing allows for flexibility in design, accommodating various layouts and installations.

- Resilience The joints formed are highly resistant to stress, environmental degradation, and temperature fluctuations.

- Cost-Effectiveness Considering the durability and longevity of well-joined HDPE pipes, the overall cost of ownership is significantly lower compared to traditional materials.

- Minimal Maintenance Once established, properly jointed HDPE systems require minimal maintenance, allowing for more efficient resource allocation.

- Environmental Safety HDPE pipes and proper jointing techniques minimize the risk of spills and leaks, protecting the environment and promoting sustainability practices.

Conclusion

The jointing of HDPE pipes is a fundamental aspect of modern piping solutions, influencing the efficiency, durability, and environmental impact of infrastructure systems. As industries continue to adopt HDPE technology, understanding the importance of effective jointing methods will remain crucial. By utilizing the most appropriate techniques, engineers and contractors can ensure that HDPE installations are reliable, safe, and sustainable for generations to come.

-

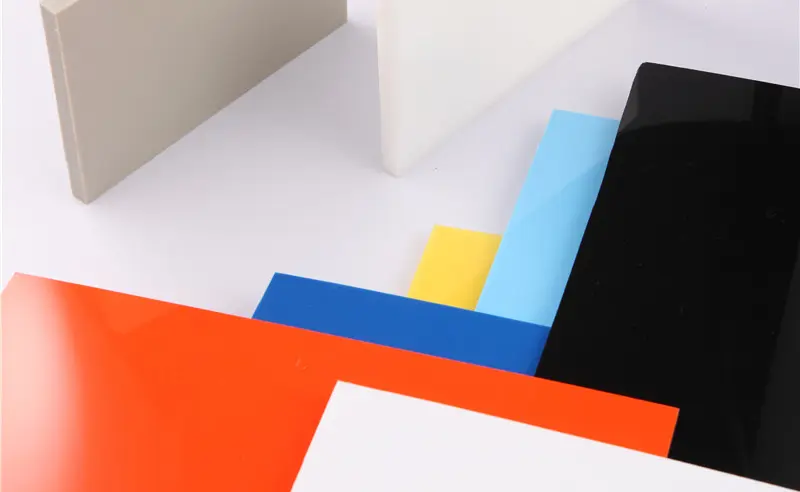

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025