Sep . 06, 2024 01:59 Back to list

High-Density Polyethylene (HDPE) Pipe Fittings - Durable and Reliable Solutions

Understanding HDPE Pipe Fittings A Comprehensive Overview

High-Density Polyethylene (HDPE) pipe fittings play a crucial role in modern piping systems, especially in industries dealing with water, gas, and wastewater management. HDPE is recognized for its excellent properties, including high strength-to-density ratio, resistance to corrosion, and longer service life, making it an ideal choice for various applications. In this article, we will explore the benefits, applications, and types of HDPE pipe fittings.

The Importance of HDPE Pipe Fittings

One of the primary advantages of HDPE pipe fittings is their flexibility. Unlike traditional piping materials like metal or PVC, HDPE can bend and flex without breaking, reducing the risk of damage during installation or in response to ground movement. Additionally, HDPE’s resistance to chemicals ensures that the fittings can handle a wide range of substances, making it suitable for use in both industrial and residential applications.

Another significant benefit is the resistance to environmental stress cracking. HDPE fittings can endure varying temperatures and are less likely to fail under harsh conditions compared to alternatives. This durability leads to lower maintenance costs over time, making HDPE a financially sound investment for businesses and homeowners alike.

Applications of HDPE Pipe Fittings

HDPE pipe fittings are utilized across various sectors. In the water supply industry, they are commonly used for transporting potable water due to their non-toxic nature and resistance to biological growth. Wastewater management systems also benefit from HDPE fittings as they provide a leak-free environment, preventing contamination of surrounding soil and groundwater.

Moreover, HDPE has gained popularity in the natural gas distribution sector. The material's ability to maintain structural integrity under pressure and its resistance to corrosion make it an excellent choice for gas pipelines. Furthermore, HDPE fittings are increasingly used in agricultural applications, such as irrigation systems, where they facilitate efficient water distribution to crops.

Types of HDPE Pipe Fittings

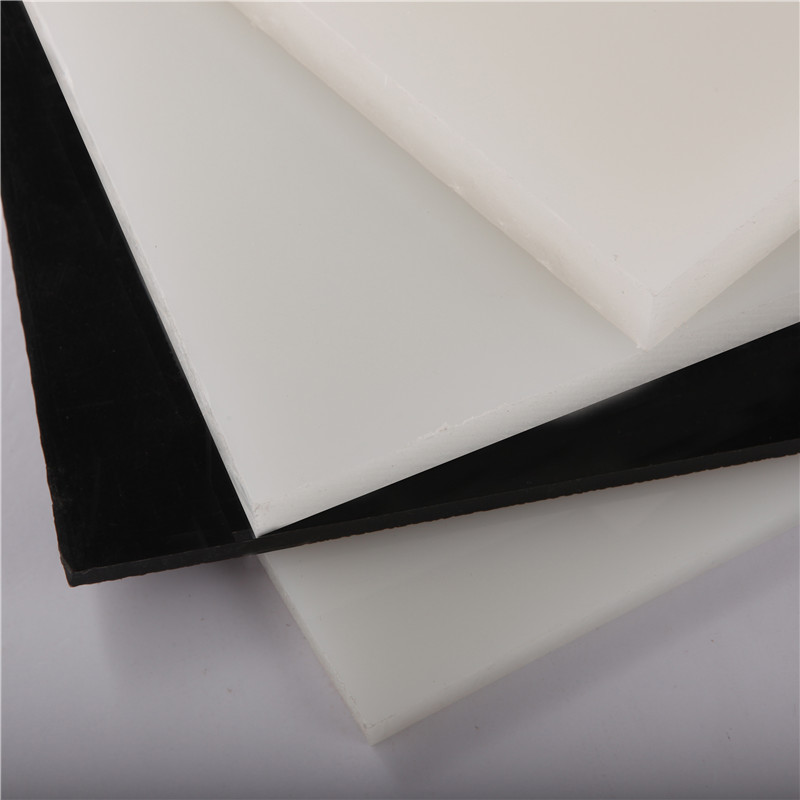

hdpe pipe fittings

There are several types of HDPE pipe fittings, each designed for specific functions. Some of the most common types include

1. Elbows These fittings change the direction of the pipe, allowing for more complex piping layouts. Standard angles include 45 and 90 degrees.

2. Tees Tees are used to connect three pipes, enabling a branch line to be connected to the main pipe. They are essential in both supply and drainage systems.

3. Reducers These fittings transition between different pipe sizes, accommodating various flow requirements in a piping system.

4. Couplings Used to connect two pipes end-to-end, couplings ensure a seamless flow of fluids. They can also serve as repair fittings for damaged pipes.

5. Flanges Flanged fittings provide an easy means of connecting or disconnecting sections of pipe, allowing for efficient maintenance and repairs.

Conclusion

In summary, HDPE pipe fittings are an indispensable component of modern piping systems. Their durability, flexibility, and resistance to corrosion make them suitable for a multitude of applications, from water supply to gas distribution. Understanding the benefits and various types of HDPE pipe fittings can help industry professionals and homeowners make informed decisions about their piping systems. As industries continue to evolve, the use of HDPE fittings is expected to grow, further solidifying their importance in infrastructure development and environmental sustainability.

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025