Dec . 16, 2024 03:58 Back to list

welding rods for pvc

When it comes to welding plastic materials, particularly polyvinyl chloride (PVC), selecting appropriate welding rods is crucial for achieving high-quality welds. PVC is widely used in various applications, such as construction, plumbing, and electrical systems, due to its durability and versatility. However, to effectively join PVC components, one must understand the significance of welding rods and the factors that influence their selection.

Welding rods for PVC are specialized fillers that are used to create strong and reliable weld joints when thermally bonding PVC materials. These rods are usually made from the same or compatible material as the base PVC being welded. This compatibility is crucial because it ensures that the weld will have similar thermal and physical properties to the base material, providing an effective bond once cooled.

.

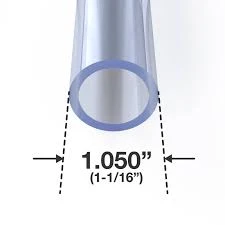

Another important aspect is the diameter of the welding rod. The diameter should be chosen based on the thickness of the PVC material being welded. Thicker materials generally require larger diameter rods to ensure adequate filler material is applied to the weld joint. On the other hand, thinner materials may necessitate smaller diameter rods to prevent excessive heat input that could potentially warp or damage the material.

welding rods for pvc

The welding process itself also influences the selection of welding rods. Common welding methods for PVC include hot air welding and ultrasonic welding. In hot air welding, specialized equipment heats the PVC surfaces and the welding rod simultaneously, allowing them to fuse together as they cool. On the other hand, ultrasonic welding utilizes high-frequency ultrasonic vibrations to generate localized heat at the joint, ensuring a quick and efficient weld. Each of these methods may require different types of welding rods, further emphasizing the need to understand the specific requirements of your welding process.

Moreover, the environmental conditions during the welding process cannot be overlooked. Factors such as temperature and humidity can affect the performance of both the PVC material and the welding rod. For instance, high humidity levels can lead to moisture absorption in the PVC, compromising weld integrity. It is advisable to conduct welding in an environment with controlled temperature and humidity levels to ensure optimal results.

Lastly, safety precautions should also be considered when working with PVC welding rods. Proper ventilation is essential, as the welding process can release fumes that may be harmful if inhaled. Using personal protective equipment (PPE) such as gloves, safety glasses, and respiratory protection can further ensure a safe working environment.

In conclusion, selecting the right welding rods for PVC is vital for achieving strong and durable welds. By considering factors such as the formulation, diameter, welding method, environmental conditions, and safety precautions, one can ensure successful welding projects that meet performance expectations. With the proper knowledge and tools, working with PVC can be a rewarding experience, leading to high-quality results that stand the test of time. Whether you are involved in industrial applications or DIY projects, understanding the nuances of PVC welding can significantly enhance your outcomes.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025