Sep . 03, 2024 06:31 Back to list

High-Quality Plastic Welding Rods for Reliable Repairs

Understanding Plastic Welding Rods A Key Component in Joining Plastic Materials

Plastic welding rods are essential tools in the realm of plastic fabrication and repair. These rods serve as fillers that create strong joints between thermoplastic materials, facilitating the construction and maintenance of a variety of plastic products. With a wide range of applications, understanding the types, uses, and advantages of plastic welding rods can greatly enhance effectiveness in both industrial and DIY projects.

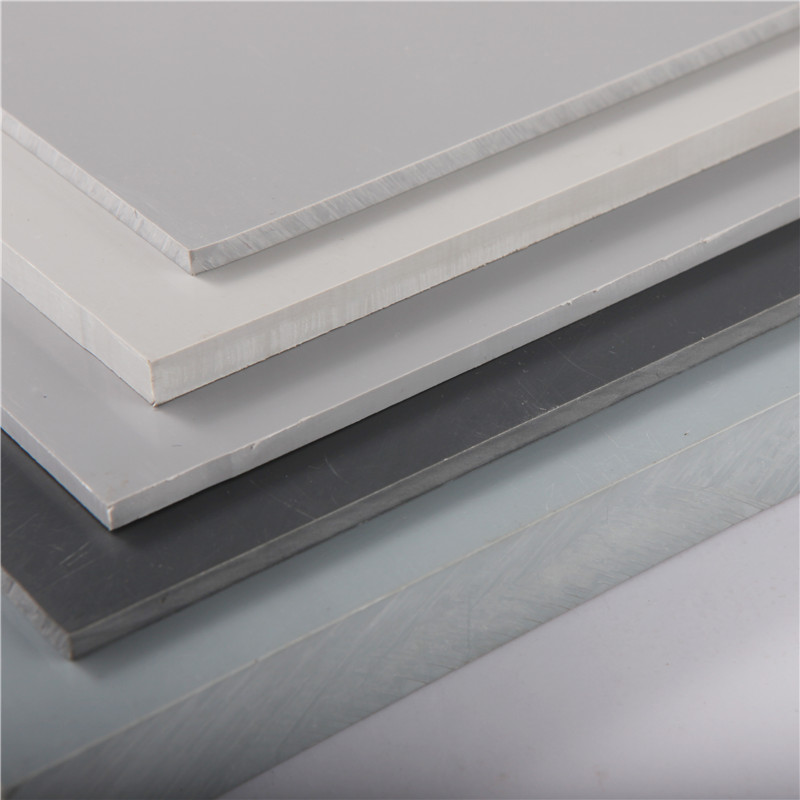

First and foremost, plastic welding rods are made from the same material as the plastics they are intended to join. Common types include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and others. When selecting a plastic welding rod, it's crucial to match the rod material with the base plastics to ensure compatibility, as this allows for a proper fusing process that maintains the integrity and strength of the weld.

The welding process itself involves heat application, which melts both the rod and the plastic substrate. Once melted, the materials bond together as they cool, forming a solid joint. Various techniques can be employed in plastic welding, including hot air welding, extrusion welding, and ultrasonic welding. Each method has its own advantages depending on the specific materials involved and the desired outcome.

plastic welding rod

Plastic welding rods are widely utilized in various industries, including automotive, construction, and marine applications. For instance, in the automotive industry, they are often used for repairing plastic parts, such as bumpers and dashboards, ensuring that vehicles maintain both functionality and aesthetics. Similarly, in construction, plastic welding rods support the assembly of items such as water tanks and pipelines.

One of the biggest advantages of using plastic welding rods is the ability to restore the structural integrity of plastic items, which can lead to significant cost savings. Rather than replacing a damaged component, welding provides a more economical solution while also contributing to sustainability. By repairing rather than disposing of products, businesses and individuals alike can minimize waste and promote environmentally friendly practices.

In conclusion, plastic welding rods are a vital component in the field of plastic welding. Their versatility and effectiveness make them indispensable for various applications, whether in a professional setting or for personal DIY projects. As technology advances, the techniques and materials associated with plastic welding continue to evolve, ensuring that this process remains a reliable method for joining plastics for years to come.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025