Mar . 04, 2025 09:15 Back to list

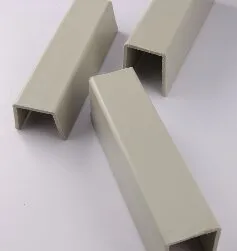

hdpe welding rod

In the realm of industrial manufacturing and construction, the role of materials and their joining techniques are crucial. Among the plethora of such materials, High-Density Polyethylene (HDPE) stands out due to its impressive attributes. The need for joining HDPE parts has brought HDPE welding rods into the spotlight. Understanding the intricacies of HDPE welding rods is essential for professionals interested in maximizing the potential of this versatile material.

In the arena of authority and trustworthiness, the choice of welding rods and equipment is significant. Reputable brands and manufacturers comply with industry standards that guarantee the material properties necessary for superior welding outcomes. Collaborating with renowned suppliers not only ensures optimum product quality but also enhances credibility in the eyes of clients and regulators. A common application of HDPE welding rods can be seen in the creation and repair of tanks, containers, and pipelines—environments where leak-proof seals are non-negotiable. The rods used must withstand the same environmental stresses as the HDPE components themselves, including exposure to chemicals and UV rays. Maintenance of welding equipment and the proper storage of HDPE welding rods are two factors that intersect expertise and trustworthiness. Equipment should be regularly calibrated and cleaned to avert inefficiencies or errors. Welding rods should be stored away from excessive heat or direct sunlight, as exposure can alter their properties, compromising their effectiveness. While HDPE welding rods provide a reliable solution in industrial settings, their success across applications heavily depends on the operator's familiarity with the material and its properties. New advances in HDPE formulations and welding technologies are constantly evolving, stressing the need for continuous learning and adaptation by professionals in the field. In conclusion, HDPE welding rods are an indispensable asset for high-quality HDPE joining solutions. Their success rests on expertise in the welding procedure, understanding the specific material properties, and ensuring the consistent application of best practices. Whether for new construction or repair, the knowledge and skill of the engineer or technician in charge lays the foundation for enduring, reliable outcomes in HDPE applications. The mastery of HDPE welding intricacies is not only a testament to professional competence but also enhances an organization's authority and trustworthiness in a competitive industrial landscape.

In the arena of authority and trustworthiness, the choice of welding rods and equipment is significant. Reputable brands and manufacturers comply with industry standards that guarantee the material properties necessary for superior welding outcomes. Collaborating with renowned suppliers not only ensures optimum product quality but also enhances credibility in the eyes of clients and regulators. A common application of HDPE welding rods can be seen in the creation and repair of tanks, containers, and pipelines—environments where leak-proof seals are non-negotiable. The rods used must withstand the same environmental stresses as the HDPE components themselves, including exposure to chemicals and UV rays. Maintenance of welding equipment and the proper storage of HDPE welding rods are two factors that intersect expertise and trustworthiness. Equipment should be regularly calibrated and cleaned to avert inefficiencies or errors. Welding rods should be stored away from excessive heat or direct sunlight, as exposure can alter their properties, compromising their effectiveness. While HDPE welding rods provide a reliable solution in industrial settings, their success across applications heavily depends on the operator's familiarity with the material and its properties. New advances in HDPE formulations and welding technologies are constantly evolving, stressing the need for continuous learning and adaptation by professionals in the field. In conclusion, HDPE welding rods are an indispensable asset for high-quality HDPE joining solutions. Their success rests on expertise in the welding procedure, understanding the specific material properties, and ensuring the consistent application of best practices. Whether for new construction or repair, the knowledge and skill of the engineer or technician in charge lays the foundation for enduring, reliable outcomes in HDPE applications. The mastery of HDPE welding intricacies is not only a testament to professional competence but also enhances an organization's authority and trustworthiness in a competitive industrial landscape.

Share:

Next:

Latest news

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025